Fat emulsion injection and production method thereof

A production method and injection technology, which are applied in the field of fat emulsion injection and its production, can solve the problems of high content of methoxyaniline, affecting output, production capacity, and large emulsion particles of the drug solution, so as to reduce the value of methoxyaniline , Improve production capacity, reduce the effect of milk particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Fat emulsion injection production method of the present invention:

[0016] Under the protection of nitrogen, add the prescription amount of soybean oil into the container, heat it in a water bath to 65-70°C, add lecithin and oleic acid, and disperse it by high-speed shearing for 10 minutes to prepare an oil phase; in addition, appropriate amount of water for injection (60 ~65°C) in the container, add the prescribed amount of glycerin (for injection) and stir to make a water phase, add an appropriate amount of 1mol / L sodium hydroxide solution, and circulate and filter through a 0.45μm filter membrane for 15 minutes to make water Mutually. Mix the oil phase and the water phase in a certain proportion through a high-speed shearing machine, add water for injection to the full amount, and then pass through the high-speed shearing machine for 10 minutes of shearing cycle, stir well to form the initial emulsion, and the temperature of the initial emulsion is controlled at 50-...

Embodiment 2

[0018] Effects of different oleic acid dosages on emulsion stability:

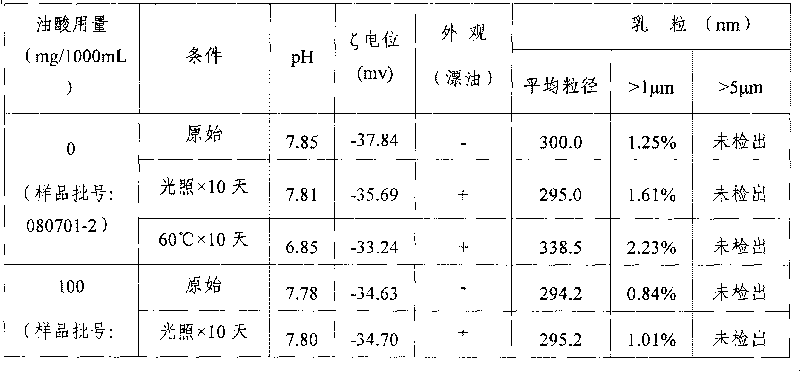

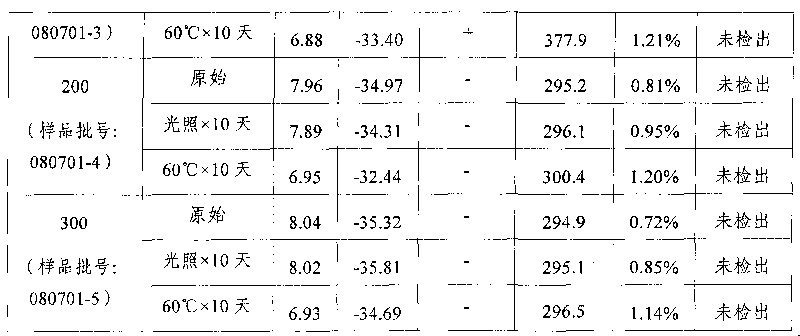

[0019] Experimental method: Taking the pH value of the emulsion, the particle size of the emulsion, the zeta potential, and the appearance (floating oil) as the evaluation indicators, the German lecithin (Lipoid-E80) was selected as the emulsifier, and different amounts of oleic acid were added as the co-emulsifier , according to the above-mentioned new process preparation fat emulsion injection, the gained sample is placed under light (4500 ± 500lx) and 60 ℃ conditions respectively for 10 days, investigates the change of each index, the results are shown in Table 1.

[0020] Table 1 Effect of different amounts of oleic acid on the stability of milk particles

[0021]

[0022]

[0023] Note: *Floating oil "+" means there is floating oil, "+" means the degree of floating oil, "-" means no floating oil

[0024] Results and discussion: After the prepared samples were subjected to light or accelerated a...

Embodiment 3

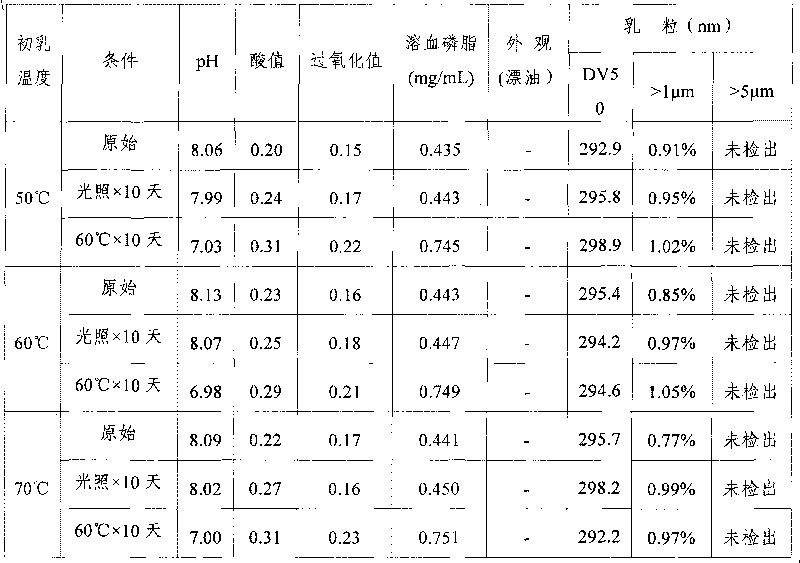

[0028] Effect of different colostrum temperature on emulsion stability:

[0029] The colostrum preparation temperature of fat emulsion injection is closely related to the quality and stability of the product. Therefore, we used pH, acid value, peroxide value, lysophospholipid, appearance, and milk particle size as evaluation indicators to investigate different See Table 2 for the effects of colostrum temperature (50, 60, 70°C) on the stability of fat emulsion injection.

[0030] Sample batch number: 080721-1 (colostrum temperature 50°C), 080721-2 (colostrum temperature 60°C), 080721-3 (colostrum temperature 70°C).

[0031] Table 2 Effect of different colostrum temperature on the stability of fat emulsion injection

[0032]

[0033] Note: *DV50 means the average particle size

[0034] *Floating oil "+" means there is floating oil, "+" means the degree of floating oil, "-" means no floating oil

[0035] The results in Table 2 show that different colostrum preparation tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com