Device and method for processing waste firedamp liquid

A treatment device and biogas slurry technology, applied in fertilization equipment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of high cost of waste biogas slurry, secondary pollution, etc., achieve less land occupation and zero discharge , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

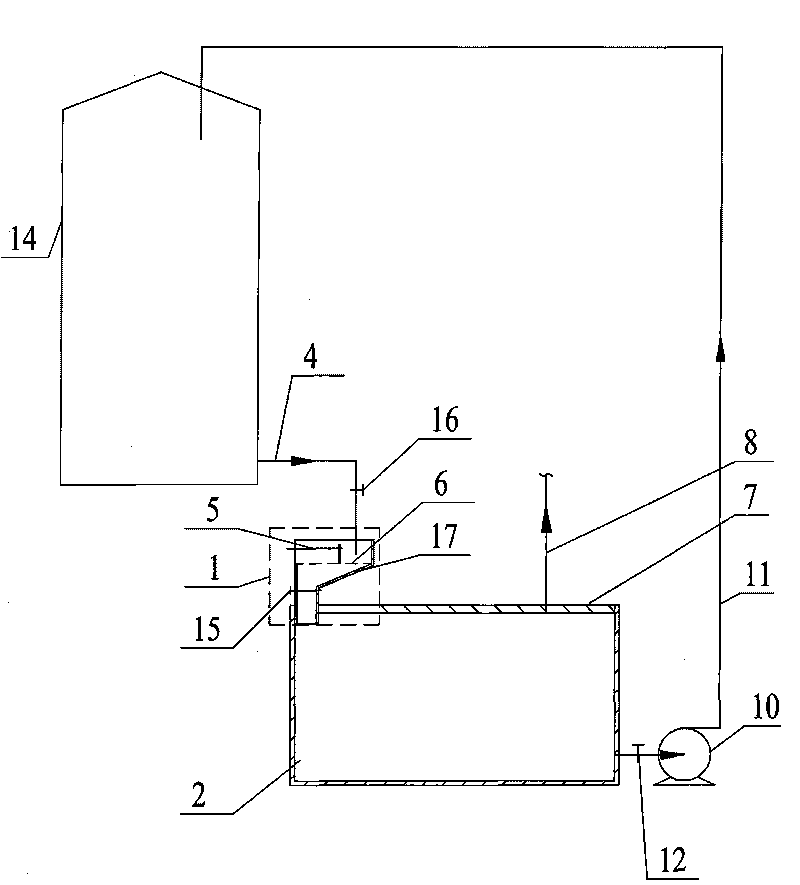

[0009] Specific implementation manner one: such as figure 1 As shown, the waste biogas slurry treatment device in this embodiment includes a sewage pump 10, an outlet pipe 11, a waste biogas slurry outflow pipe 4, a separation device 1, a fermentation tank 2 and a cover plate 7. The separation device 1 consists of a funnel. A shaped shell 17, a slag cleaner 5 and a filter screen 6. The slag cleaner 5 and the filter screen 6 are arranged in the upper cylindrical cavity of the funnel-shaped shell 17 from top to bottom, and the cover plate 7 is arranged in the fermentation tank 2. The upper end surface of the biogas fermentation tank 14 is hermetically connected with the fermentation tank 2; the separation device 1 is arranged below the biogas fermentation tank 14. The lower end side wall of the biogas fermentation tank 14 communicates with the separation device 1 through the waste biogas liquid outflow pipe 4, and the funnel-shaped shell 17 The lower end is installed on the cover ...

specific Embodiment approach 2

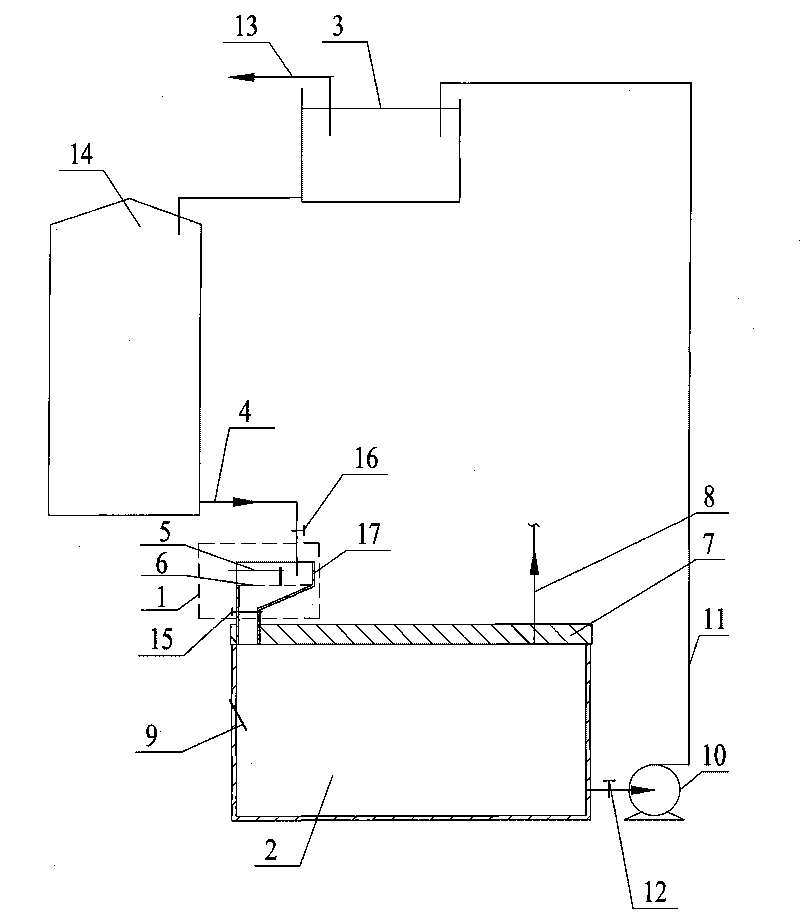

[0012] Specific implementation manner two: such as figure 2 As shown, the processing device of this embodiment further includes a batching tank 3, and the other end of the outlet pipe 11 is in communication with the upper end of the biogas fermentation tank 14 through the batching tank 3. The batching tank 3 is also provided with a feed pipe 13. The other components and connection relationships are the same as in the first embodiment.

[0013] The batching tank 3 in this embodiment can be constructed with a brick-concrete structure, with anti-corrosion treatment inside and waterproof protection outside, which has good corrosion resistance and reduces production costs.

[0014] Specific implementation manner three: such as figure 1 with 2 As shown, the processing device of this embodiment further includes a temperature sensor 9 which is arranged on the side wall of the fermentation tank 2 and the measuring end of the temperature sensor 9 is located in the fermentation tank 2. Othe...

specific Embodiment approach 8

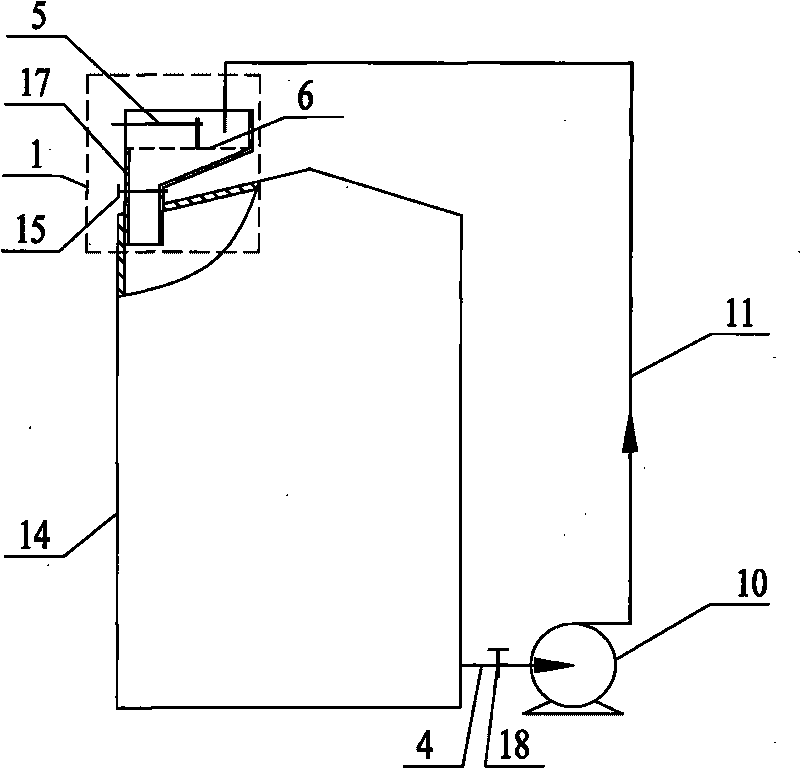

[0020] Specific implementation manner eight: such as image 3 As shown, the processing device of this embodiment further includes a separation device control valve 15 and a first waste biogas slurry flow control valve 18. The separation device control valve 15 is arranged on the cone of the funnel-shaped shell 17 and is located in the fermentation tank. 2 outside; the first waste biogas slurry flow control valve 18 is set on the waste biogas slurry outflow pipe 4. The other composition and connection relationship are the same as in the seventh embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com