Method for synthesizing high-purity polysorbate-80

A technology of polysorbate and synthesis method, which is applied in the directions of chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problem of poor color of polysorbate-80 (I), low purity of polysorbate-80, and product quality Difficult to control and other problems, to achieve perfect emulsification and solubilization performance, good safety in clinical use, and less harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

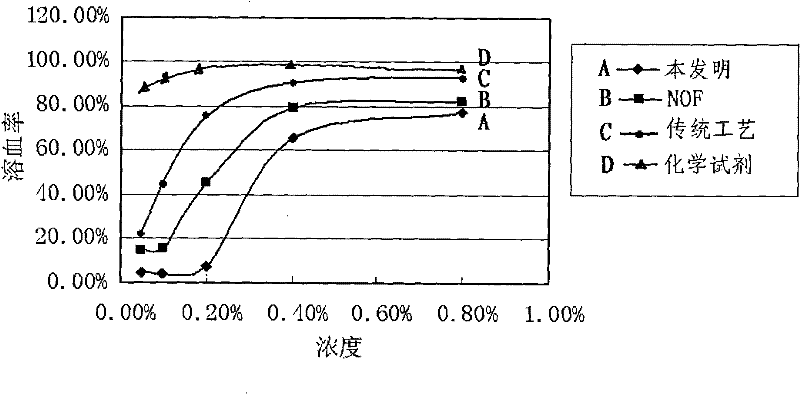

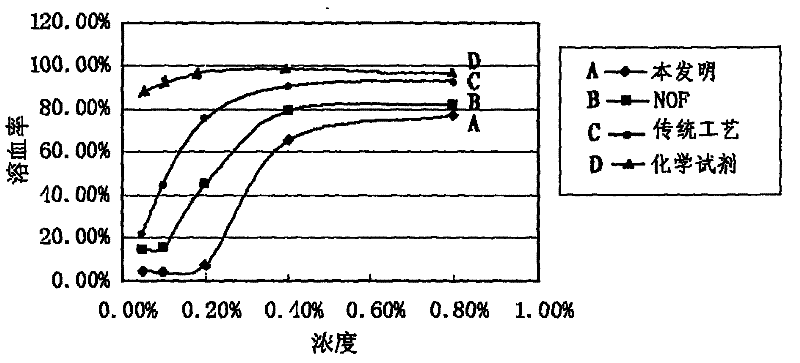

Image

Examples

Embodiment 1

[0044] The synthesis of embodiment 1 sorbitan

Embodiment 11

[0045] Example 1.1 Put 3500g of 70% sorbitol into the kettle, dehydrate at 100-120°C for 3 hours, when the temperature is lowered to 80°C, add 120ml of 20% sulfuric acid aqueous solution, and stir the reaction for 5 hours under 750mmHg vacuum and 105-110°C; use 20% The aqueous solution of sodium hydroxide was neutralized to neutral, decolorized with activated carbon, filtered, evaporated to dryness under reduced pressure, and dried in vacuo to obtain white solid sorbitan with a hydroxyl value of 1100 mgKOH / g.

Embodiment 12

[0046] Example 1.2 is basically the same as Example 1.1, but with the following changes, 120ml of 20% sulfuric acid aqueous solution is replaced by 24.5g of phosphorous acid, and the hydroxyl value of the obtained sorbitan is 1092mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com