ph controlling technology for converting municipal sludge into acetic acid

A municipal sludge and acetic acid technology, applied in the field of waste recycling, can solve the problems of insufficient SCOD degradation capacity, increased wastewater treatment costs, and high SCOD index, and achieve the effects of reducing SCOD index, low cost, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

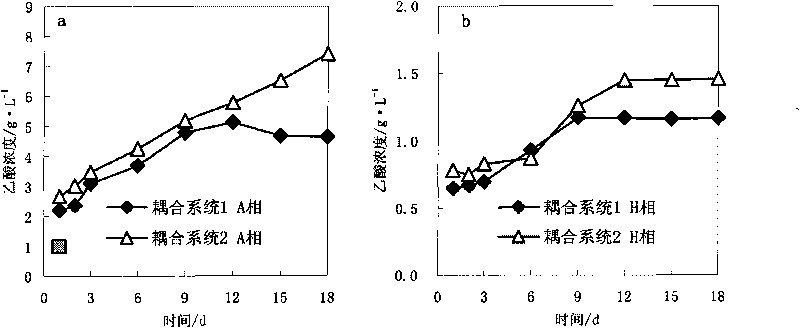

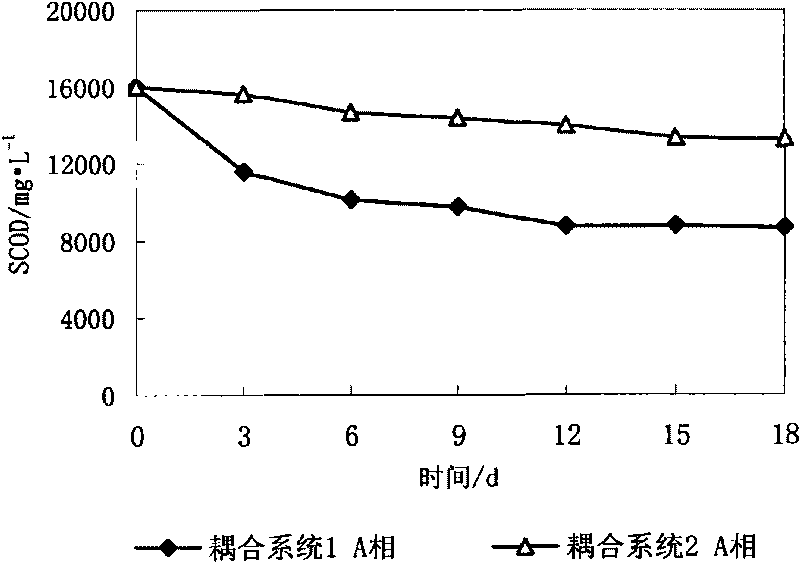

[0020] Method 1: Coupled system without process pH control

[0021] The initial SCOD value of waste municipal sludge in phase A is 16000mg / L.

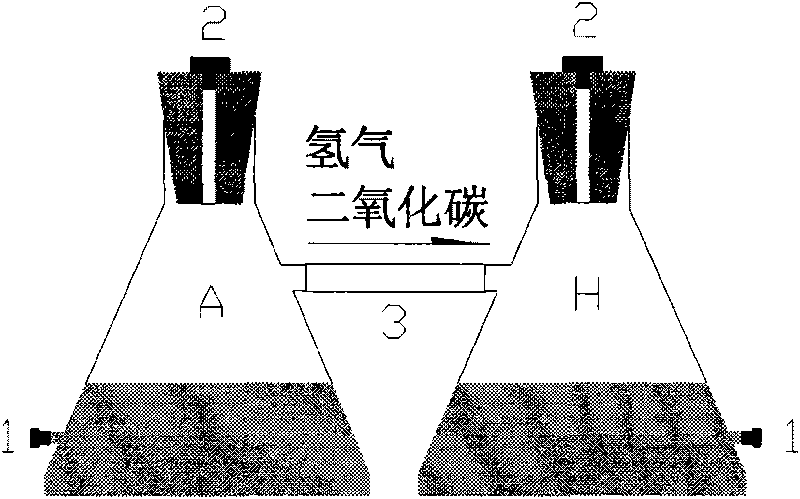

[0022] Hydrogen-producing acetic acid phase (phase A): Seed sludge with a concentration of 4gVS / L (VS refers to volatile solids), sludge pretreatment liquid, the initial pH is adjusted to 10, and the pH is not controlled during the fermentation process.

[0023] Hydrogen consuming and acetogenic phase (H phase): seed sludge, concentration 6gVS / L, initial pH 6.5, pH is not controlled during the fermentation process.

[0024] Fermentation conditions: fill with nitrogen for 10-40 minutes, seal, ferment at 30-40°C, mix the seed mud and substrate by magnetic stirring or other methods.

[0025] Method 2: Coupled system to control process pH

[0026]The initial SCOD value of waste municipal sludge in phase A is 16000mg / L.

[0027] Hydrogen and acetic acid production phase (phase A): Seed sludge, concentration 4gVS / L, sludge pretreatment li...

Embodiment 2

[0033] Embodiment 2: Adopt the coupling system of pH control technology (A phase initial pH9.0)

[0034] The initial SCOD value of waste municipal sludge in phase A is 16000mg / L.

[0035] Hydrogen and acetic acid production phase (Phase A): seed sludge, concentration 4gVS / L, sludge pretreatment liquid, initial pH is adjusted to 9, and pH is adjusted to 9 once a day starting from 13 days of fermentation.

[0036] Hydrogen consuming and acetogenic phase (H phase): Seed slime with a concentration of 6gVS / L and an initial pH of 6.5. During the fermentation process, the pH was adjusted once a day to keep the pH at 6.5.

[0037] Fermentation conditions: fill with nitrogen for 10-40 minutes, seal, ferment at 30-40°C, mix the seed mud and substrate by magnetic stirring or other methods.

[0038] Table 1 Coupling system using pH control process (phase A initial pH9.0)

[0039] time (d)

Embodiment 3

[0040] Embodiment 3: Adopt the coupling system of pH control technology (A phase initial pH10.0)

[0041] The initial SCOD value of waste municipal sludge in phase A is 16000mg / L.

[0042] Hydrogen and acetic acid production phase (phase A): the concentration of the seed sludge is 4gVS / L, the initial pH is adjusted to 10, and the pH is adjusted once a day from the 13th day of fermentation, and the pH is adjusted to 10.

[0043] Hydrogen consuming and acetogenic phase (H phase): the seed sludge concentration is 6gVS / L, the initial pH is 6.5, and the pH is adjusted once a day during the fermentation process to keep the pH value at 6.5.

[0044] Fermentation conditions: fill with nitrogen for 10-40 minutes, seal, ferment at 30-40°C, mix the seed mud and substrate by magnetic stirring or other methods.

[0045] Table 2 Coupling system adopting pH control process (initial pH of phase A is 10.0)

[0046] time (d)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com