Basalt fiber and carbon fiber compound geogrid with electric heating function

A basalt fiber and composite geotechnical technology, applied in the direction of roads, pavement details, road construction reinforcements, etc., can solve the problems of difficulty in dispersing conductive fillers, weakening the mechanical properties of asphalt, weakening the strength of the pavement, etc., so as to delay the occurrence of cracks and prolong the Fatigue life, deflection reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

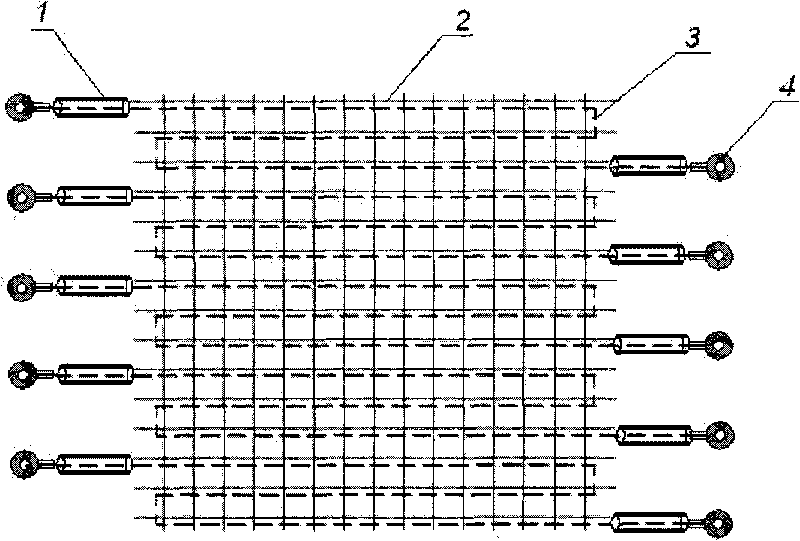

[0020] Embodiment 1: Adopt Taili continuous carbon fiber produced by Formosa Plastics Group, first coat epoxy resin (grade: E-44) on the surface of the carbon fiber bundle, and paste it on the mesh with a mesh size of 25mm×25mm when the epoxy resin is not completely cured On the weft yarn of the basalt fiber geogrid (produced by Zhejiang Shijin Basalt Fiber Co., Ltd.). And put a braided plastic sleeve with a length of about 5cm on the place where the carbon fiber bundle protrudes from the grid, so as to prevent the carbon fiber from breaking when it protrudes from the grid. Finally, copper lugs are connected to both ends of the carbon fiber and fixed on the copper plate electrodes.

[0021] The structure of the electric heating pavement used for manufacturing is as follows: the composite pavement lower layer is prepared according to C30 concrete, and the mix ratio is: cement: water: sand: gravel=1:0.4:1.23:3. The cement is 42.5 ordinary Portland cement produced by Huaxin Ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com