Fully automatic gas explosion proof equipment

An explosion-proof equipment and fully automatic technology, which is applied in the direction of gas discharge, mining equipment, dust prevention, etc., can solve the problems of equipment withdrawal, spending a lot of time, equipment damage, etc., and achieve the effect of rapid response, simple structure, and reduced gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

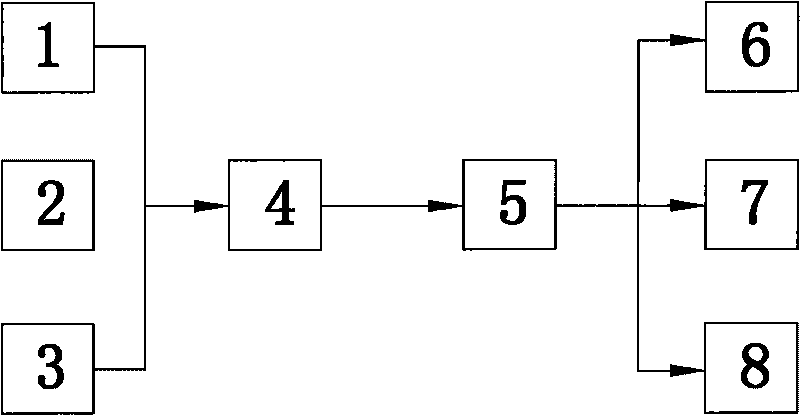

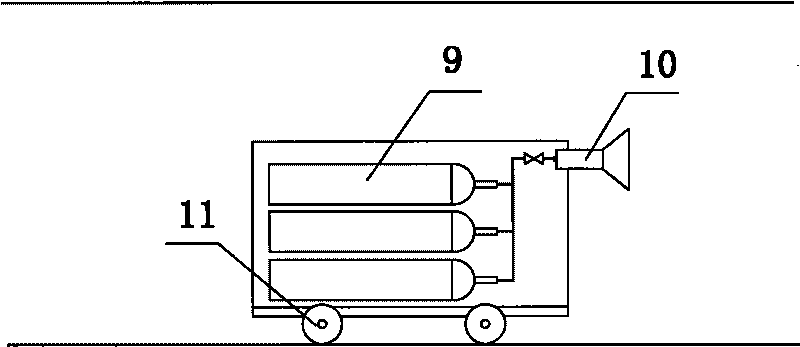

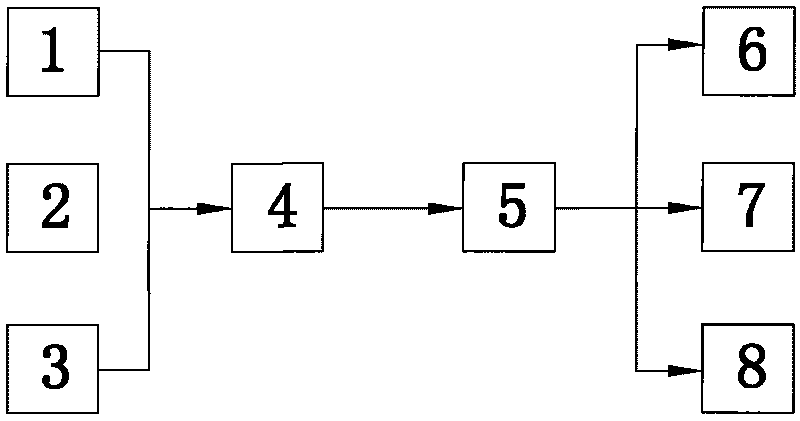

[0019] figure 1 It is a structural schematic diagram of the utility model, figure 2 It is a schematic structural diagram of the utility model; as shown in the figure: the fully automatic gas explosion-proof equipment of this embodiment includes a gas monitoring system, an explosion-proof system, an alarm system and a control system; the gas monitoring system is used to monitor the gas concentration and Temperature; including a gas sensor 1, a temperature sensor 2, a pressure sensor 3 and a signal processing unit 4; the explosion-proof system is used to rapidly release a large amount of inert gas when there is a danger of explosion, so as to reduce the concentration of gas, and can assist in the explosion or fire. Fire extinguishing; including an electric valve 6, an inert gas compression container 9 controlled by the electric valve 6; the inert gas compression container 9 is arranged in the casing, and is connected with the injection port 10 through the electric valve 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com