Active control system and control method for radiation noise of vibration structure

A technology for radiating noise and control systems, applied in control/adjustment systems, mechanical oscillation control, non-electric variable control, etc., can solve the problem of sound radiation reduction, and achieve the effect of compact structure, easy implementation, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

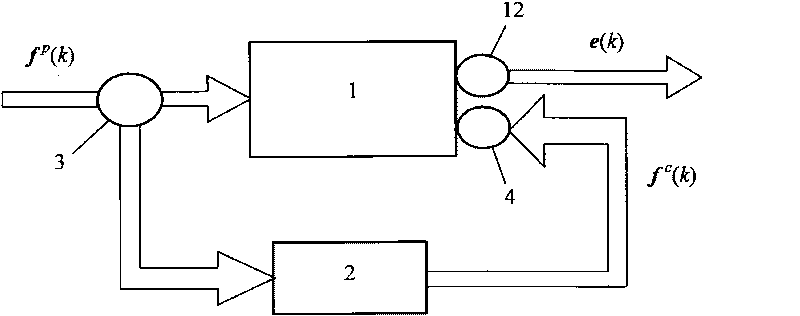

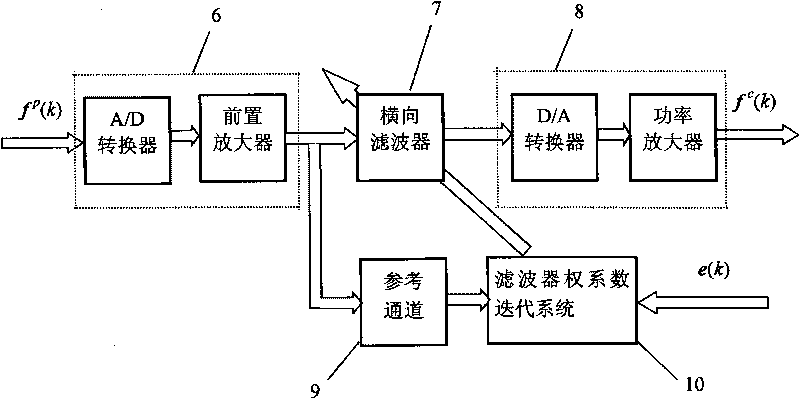

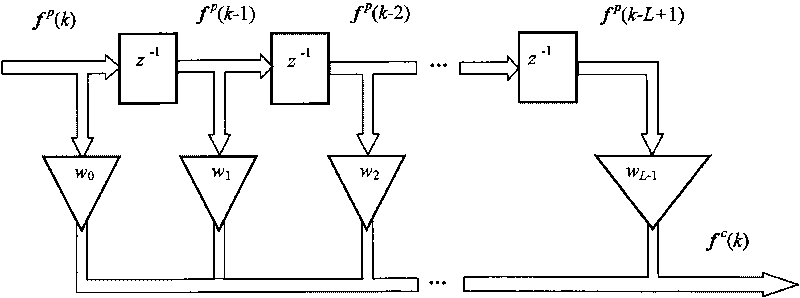

[0022] Such as figure 1 , the active control system of the present invention is installed on the vibrating structure 1, including K piezoelectric sensors 3, adaptive feedforward controller 2, N piezoelectric actuators 4, and error sensor 12. where f p (k) is the K external disturbance forces acting on the vibrating structure 1, the external disturbance forces cause the vibration of the vibrating structure 1, and then radiate noise, and K piezoelectric sensors 3 are installed on the K external disturbance forces f p At the action point of (k), K piezoelectric sensors 3 are used to measure K external disturbance forces f acting on the vibrating structure 1 that cause the structure to vibrate and radiate noise p (k) Reference signal. The adaptive feedforward controller 2 is connected to the output ends of K piezoelectric sensors 3 . The amplified K external disturbance forces f from K piezoelectric sensors 3 p (k) The reference signal is input to the adaptive feedforward cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com