Transductor used for direct-current current transformation valve

A DC converter valve and reactor technology, applied in the field of saturable reactors, can solve the problems of complex electrical design and mechanical strength design of saturable reactors, achieve structural design and industrialized production, simplify structure, and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

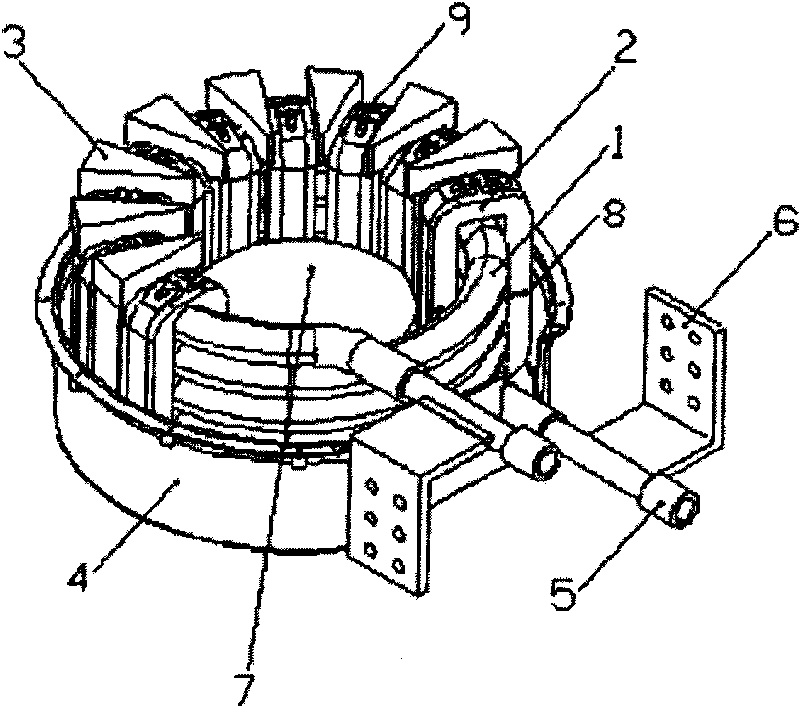

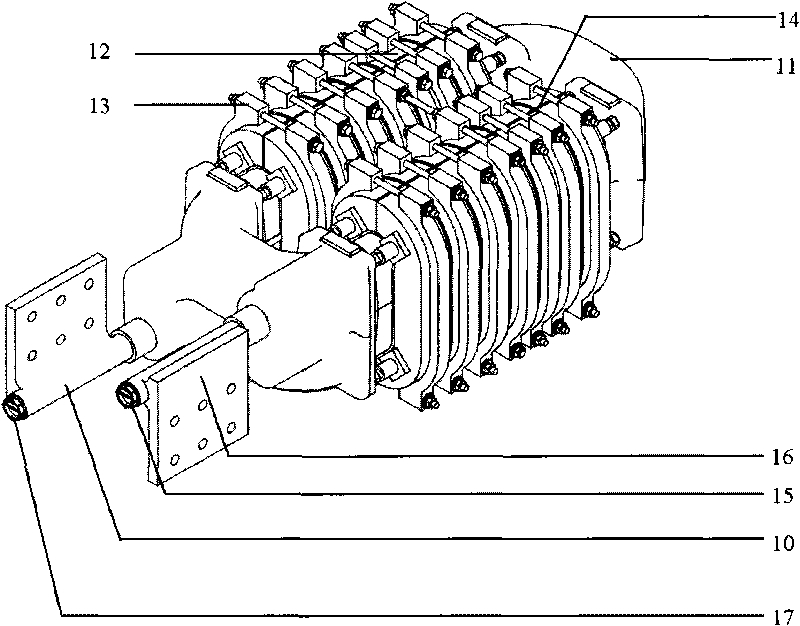

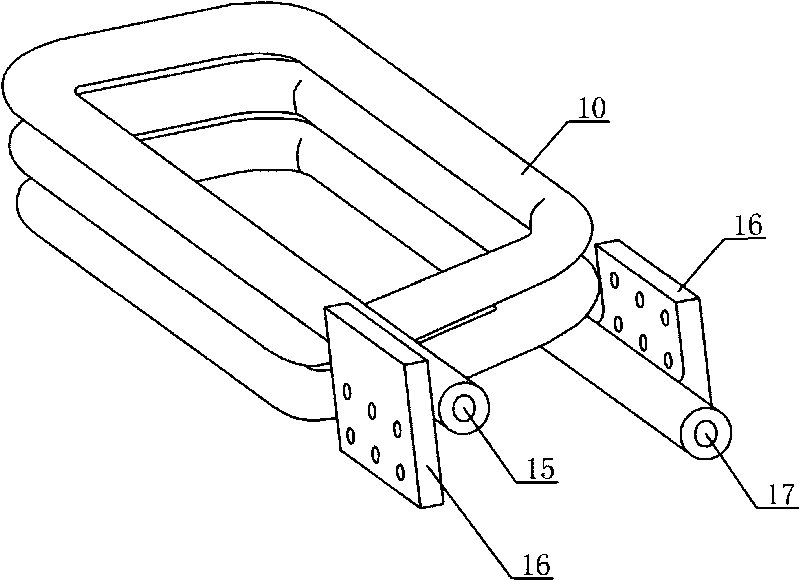

[0021] The saturable reactor of the present invention will be further described in detail with reference to the accompanying drawings.

[0022] Such as figure 2 , image 3 As shown, a saturable reactor for a DC transmission converter valve includes a coil 10, an epoxy resin 11, an iron core 12, a metal clip 13, an air gap 14, and a copper bar 16. The coil 10 is wound into an elliptical track shape, and the coil There are two sections of linear structures with a certain length along the circumferential direction, which are convenient for fixing and hoisting. The coil is made of aluminum with low copper content; the turns are reliably fixed and insulated by epoxy resin 11, and epoxy resin has certain elasticity. , can reduce the vibration of the reactor during operation and reduce the noise. The surface of the epoxy resin is filled with a conductive metal layer, and the C-shaped structure iron core 12 is attached to the surface of the conductive metal layer, and is fastened i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com