Optical element, titanium oxide glass used for the optical element, and light emitting method and light amplifying method using titanium oxide glass

A technology of oxide glass and optical components, applied in the direction of optical components, optical, electrical components, etc., can solve the problems of low durability and easy deterioration of fluoride glass, and achieve the effect of high-intensity up-conversion luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

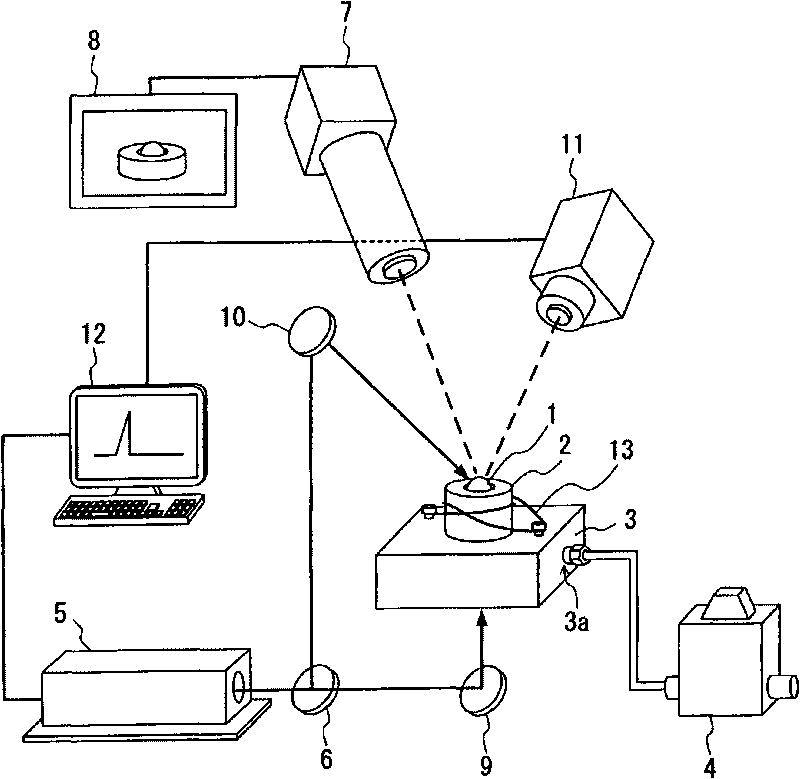

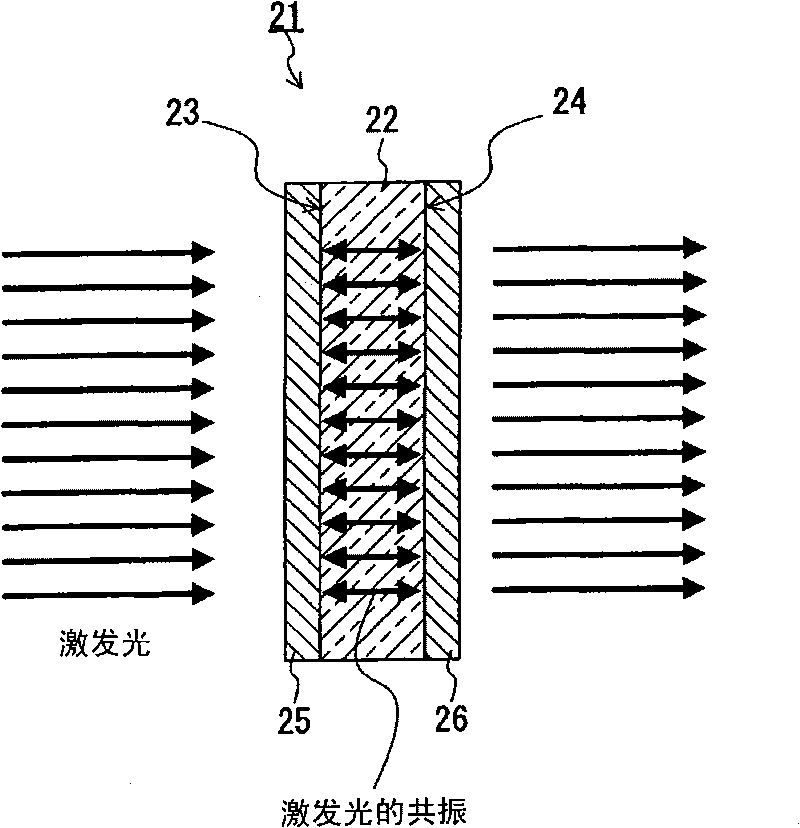

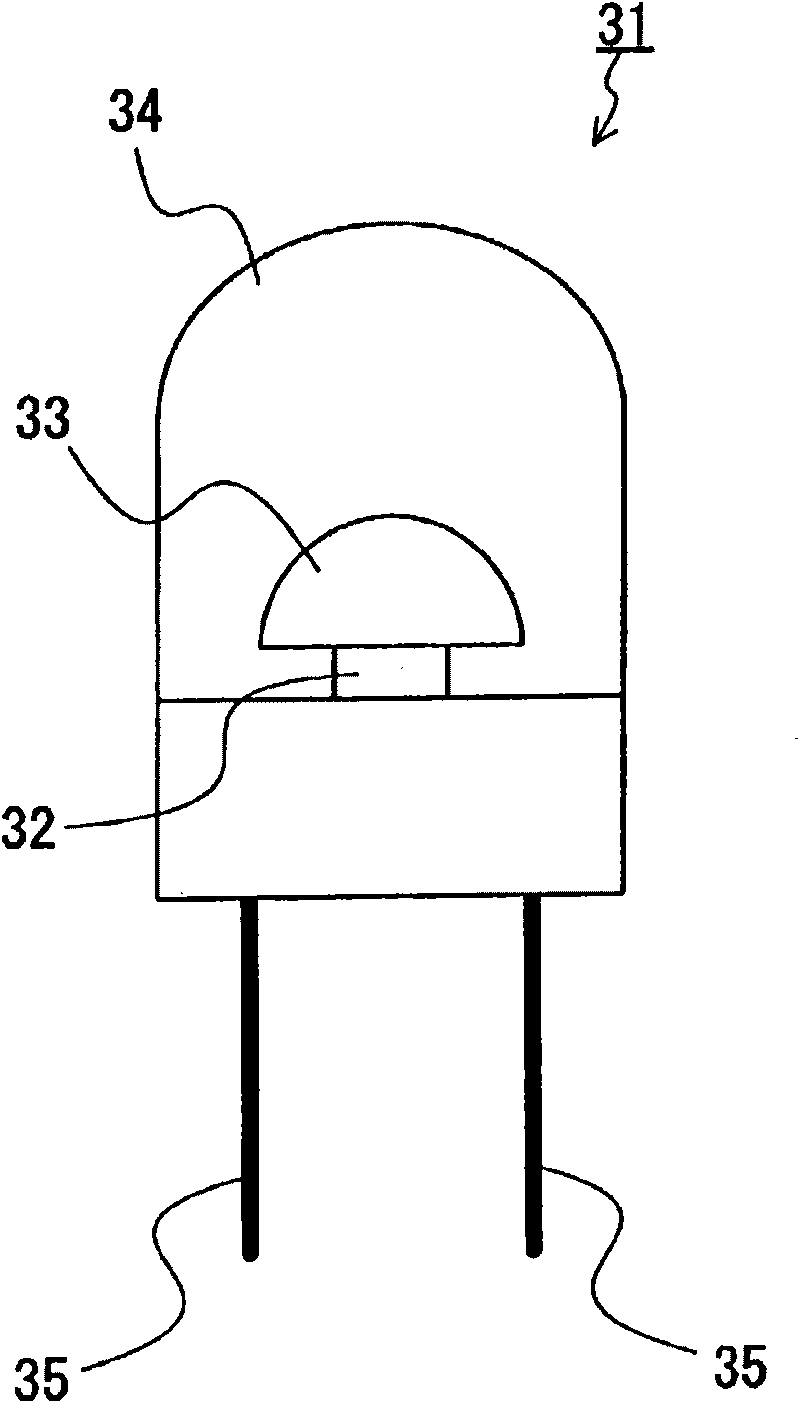

Method used

Image

Examples

Embodiment 1

[0077] By suspension method, made of BaTi 2 o 5 A spherical glass sample with a basic composition and further addition of rare earth elements. The sample manufactured in this embodiment has the formula Ba 1-x1-x2-x3 Er x1 Yb x2 Ti y o z Glasses of the composition indicated. As shown in Table 1, samples 1-1 to 1-4 are samples in which Er is added as a rare earth element in the basic composition, and samples 1-5 to 1-11 are samples in which Er and Yb are added as rare earth elements in the basic composition sample.

[0078] (Procedure for manufacturing spherical glass by suspension method)

[0079] First, the raw material powders were weighed and mixed to obtain the respective compositions shown in Table 1. Next, the weighed oxide powder and ethanol were put into an agate mortar, wet-mixed (the first wet-mixing), and calcined. Specifically, the dried mixed powder was put into an electric furnace and calcined at 1000° C. for 12 hours to sinter the mixed powder. Thereaf...

Embodiment 2

[0093] Same as Example 1, by suspension method, make BaTi 2 o 5 A spherical glass sample with a basic composition and further addition of rare earth elements. The sample that present embodiment manufactures has formula Ba 1-x2-x3 Yb x2 T m x3 Ti y o z Glasses of the composition indicated. As shown in Table 1, samples 2-1 and 2-2 are samples in which only Tm is added as a rare earth element, and sample 2-3 is a sample in which both Tm and Yb are added as rare earth elements.

[0094] Differential thermal analysis (DTA) measurements were performed on the various samples produced by the method described above. From this result, it can be confirmed that these samples have a glass transition point and a crystallization temperature. That is, it was confirmed that all samples 2-1 to 2-3 of this example were glassy at room temperature. In addition, among samples 2-1 to 2-3, the DTA measurement results of sample 2-2 are as follows: Figure 8 shown.

[0095] Using the same ap...

Embodiment 3

[0097] Same as Example 1, by suspension method, make BaTi 2 o 5 A spherical glass sample with a basic composition and further addition of rare earth elements. The sample that present embodiment manufactures has formula Ba 1-x2 Yb x2 Ti y o z Glasses of the composition indicated. That is, spherical glasses of samples 3-1 to 3-3 in which only Yb was added as a rare earth element were manufactured and evaluated (see Table 1).

[0098] Differential thermal analysis (DTA) measurements were performed on the various samples produced by the method described above. Measurement results such as Figure 9 shown. From this result, it can be confirmed that these samples have a glass transition point and a crystallization temperature. That is, it was confirmed that all samples 3-1 to 3-3 of this example were glassy at room temperature.

[0099] Using the same apparatus and conditions as in Example 1, the spherical glass was irradiated with excitation light to study up-conversion lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com