Dry-cold grinding device for grinding machine

A grinding and dry cooling technology, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that cannot meet the needs of production, increase the amount of cutting fluid, and intensify the impact on the environment. , to reduce production costs, save resources, and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

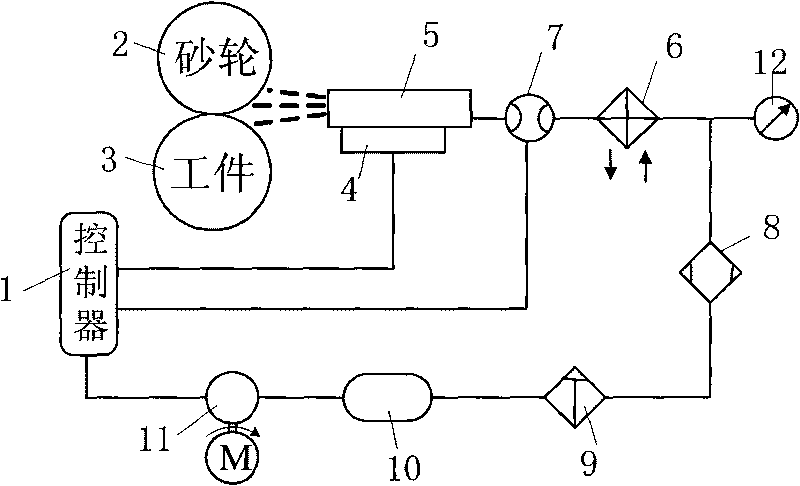

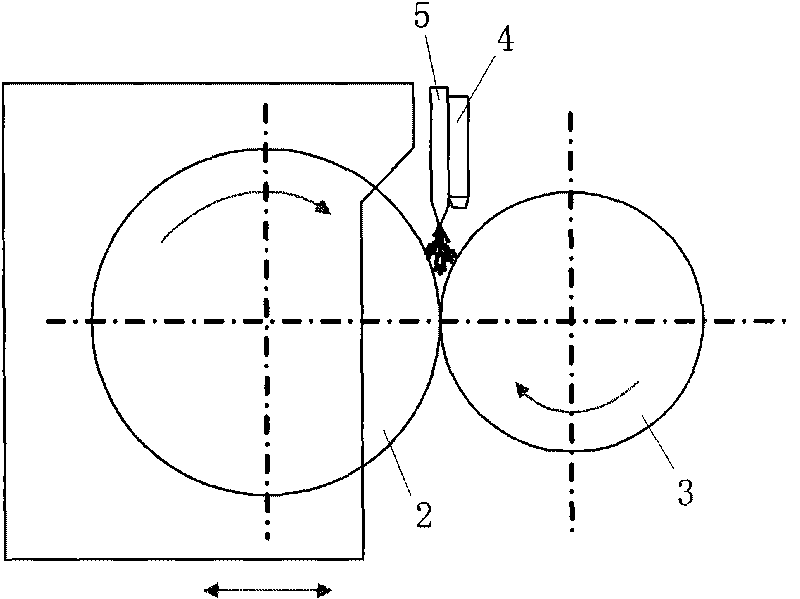

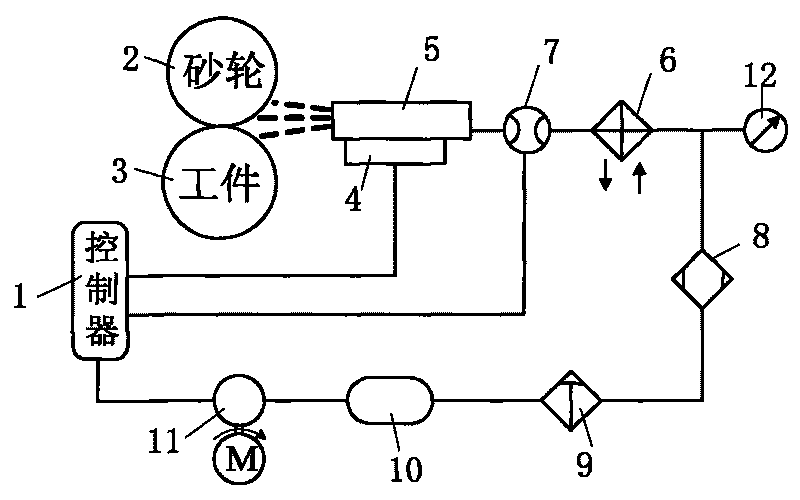

[0014] see figure 1 , figure 2 , a dry-cooling grinding device for a grinder, comprising an infrared thermometer 4, a controller 1, a nozzle 5 and an air cooling mechanism, the infrared thermometer 4 and the nozzle 5 are installed on the grinding wheel 2 and the workpiece 3 are engaged with each other Directly above the working area, the nozzle 5 is connected to the air cooling mechanism. The output signal of the infrared thermometer 4 is processed and converted into a voltage signal and then connected to the controller 1. The controller 1 controls the flow rate output by the air cooling mechanism to the nozzle 5.

[0015] Described air cooling mechanism comprises air refrigeration unit 6, flow control valve 7, air purifier 8, air drier 9, air storage tank 10 and air compressor 11; Air compressor 11, air storage tank 10, air drier 9 , air pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com