Silicon material substrate and construction method thereof

A construction method and technology of silicon materials, applied in the direction of metal material coating technology, microstructure technology, microstructure devices, etc., to achieve the effects of easy acquisition, stable hydrophobic performance, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

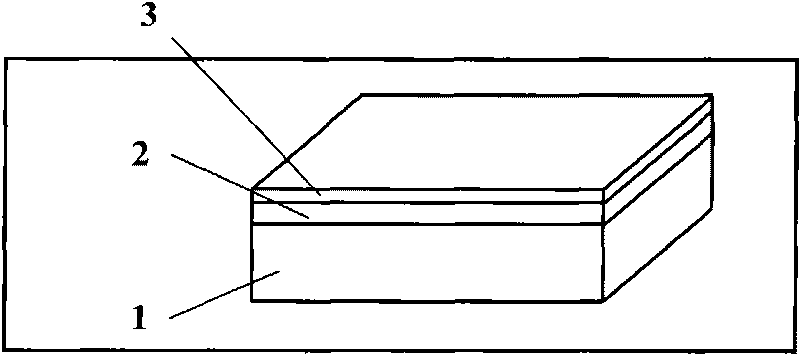

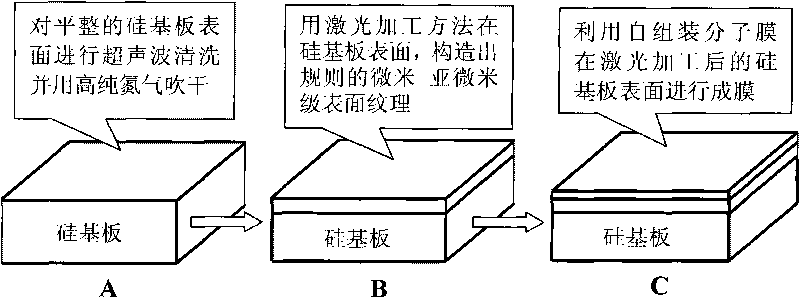

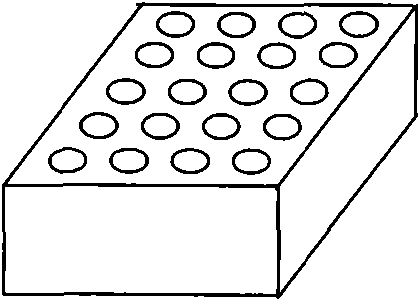

[0030] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-5 As shown, a silicon material substrate includes a silicon substrate 1 , a texture layer 2 and a film-forming layer 3 , and the texture layer 2 is between the silicon substrate 1 and the film-forming layer 3 . The texture layer 2 is obtained by laser processing the surface of the silicon substrate 1 , and the film-forming layer 3 is obtained by forming a self-assembled molecular film on the texture layer 2 . The texture layer 2 has a micron-submicron surface texture structure. The texture structure is dot matrix texture, linear texture or grid texture. The self-assembled molecular film is 1H, 1H, 2H, 2H-perfluorooctyltrichlorosilane with a purity of 97%, FOTS for short.

[0031] Such as figure 2 Shown, a kind of construction method of the silicon material substrate with superhydrophobic property comprises the following steps:

[0032] A. Pretreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com