Method for processing percolation liquid of domestic garbage

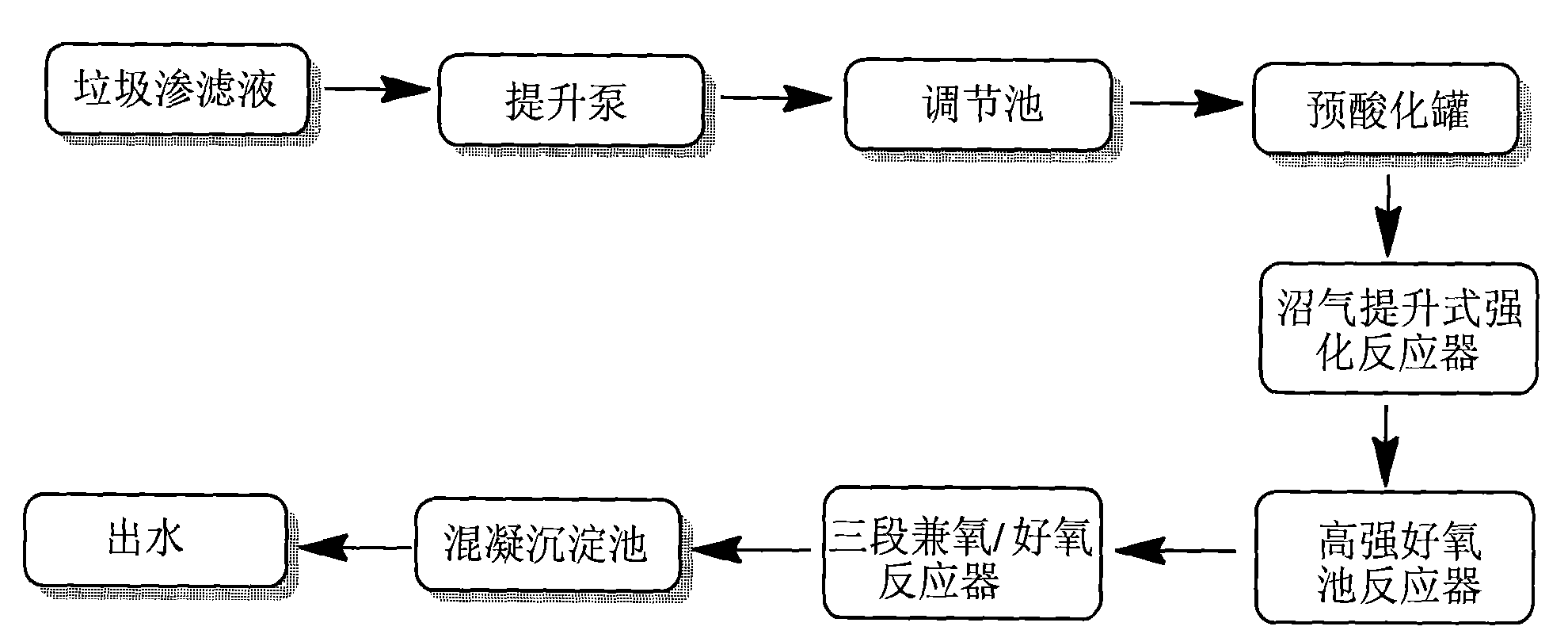

A domestic waste and treatment method technology, which is applied in the field of domestic waste leachate treatment, can solve the problems of large fluctuations in leachate water quality, difficulty in maintaining stability in the system, and high heavy metal content, and achieve optimal connection combination and optimal control technology, and strengthen phosphorus removal. High denitrification effect and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

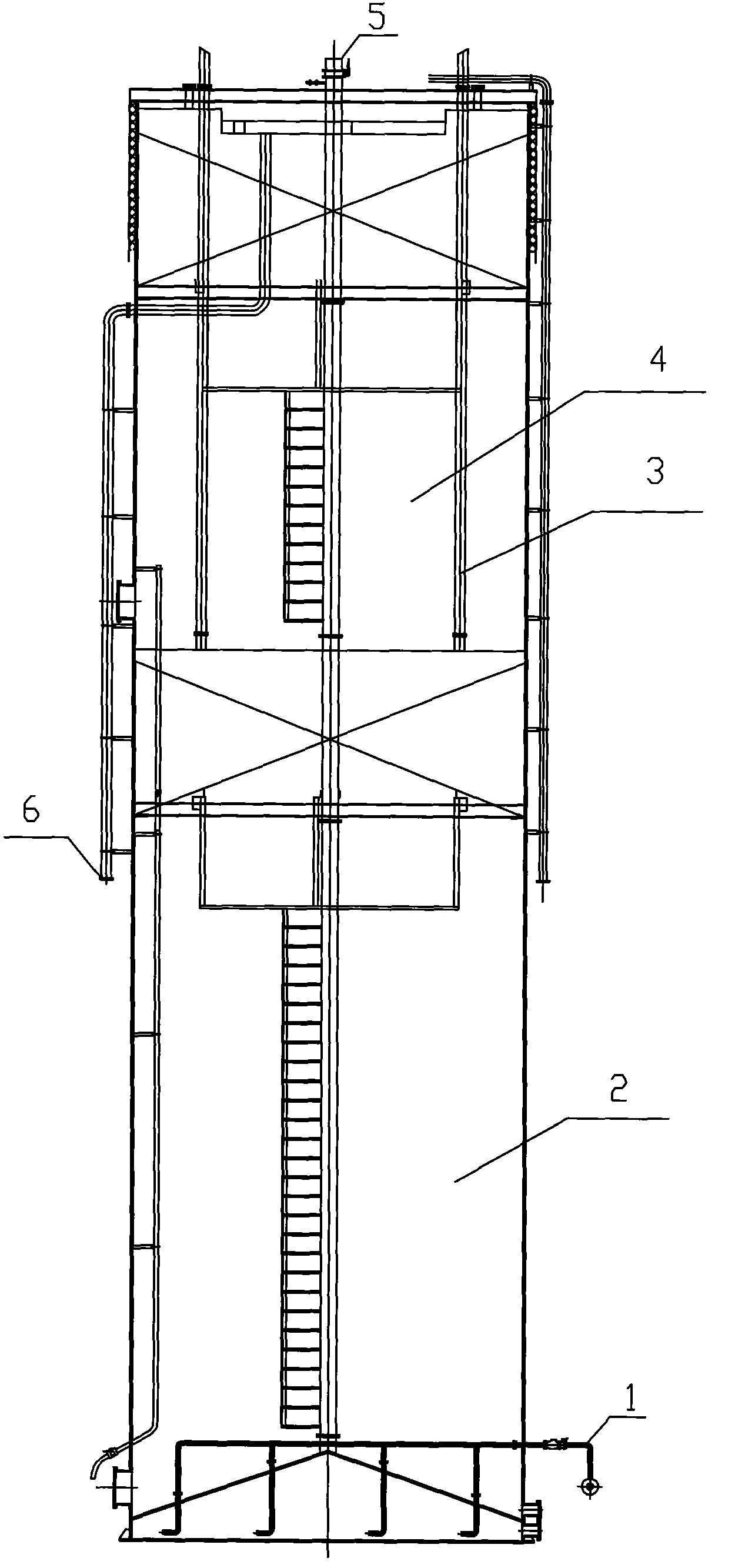

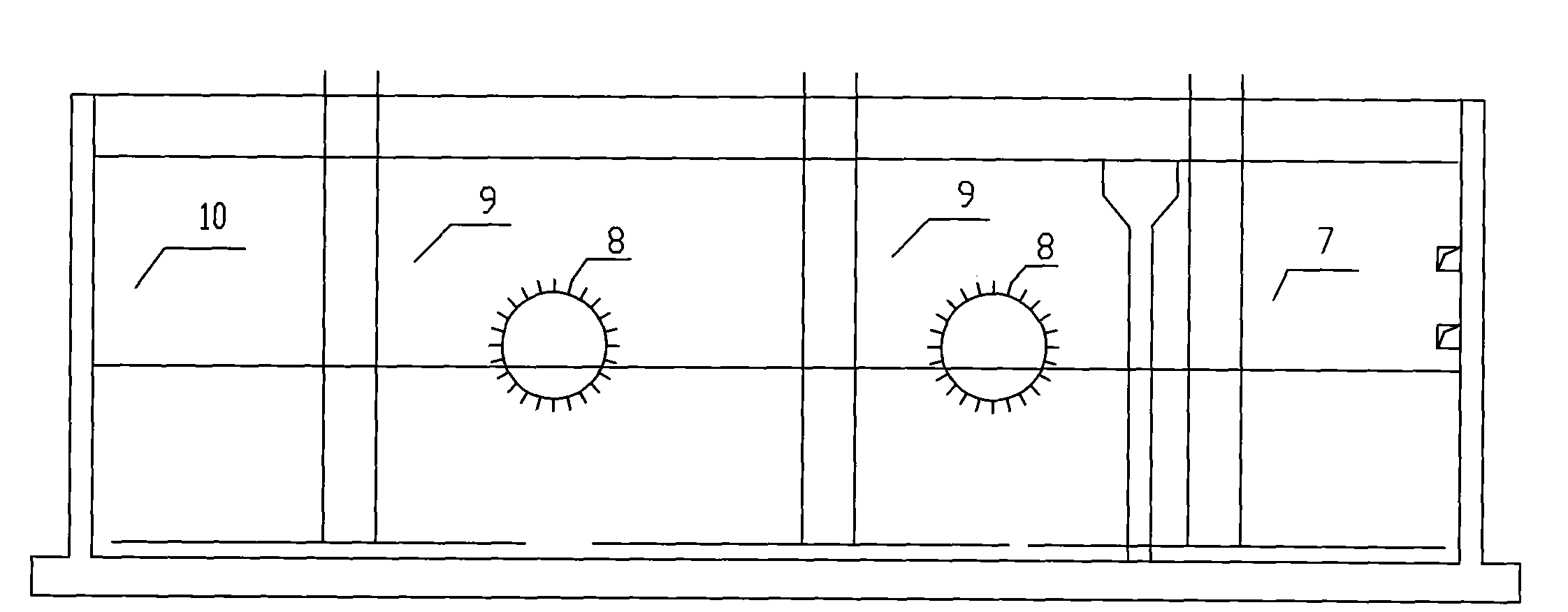

[0030] (1) Start-up of the anaerobic reactor: take the biogas lifting reactor as the anaerobic reactor, first inoculate the biogas lifting reactor with sludge, the volume of the sludge is 1 / 2 of the volume of the anaerobic reactor, according to the gradient Gradually increase the load of the anaerobic reactor, carry out sludge domestication, control the temperature at 32°C, and start-up process takes 30 days;

[0031] (2) Inject the leachate of the waste incineration plant into the adjustment tank by the lift pump, and after stirring evenly, adjust the pH to 6.0;

[0032] (3) Inject the leachate in the adjustment tank into the pre-acidification tank for pre-acidification treatment for 6 hours;

[0033](4) Anaerobic fermentation: The leachate after pre-acidification treatment is injected into the biogas lifting reactor by a circulating water pump, and anaerobic fermentation is carried out at a temperature of 32°C, with a residence time of 20 hours and a flow rate of 3 cubic met...

Embodiment 2

[0041] Embodiment 2: a kind of domestic waste incineration plant leachate treatment method, comprises the following treatment process:

[0042] (1) Start-up of the anaerobic reactor: the biogas lifting reactor is used as the anaerobic reactor, and the biogas lifting reactor is first inoculated with sludge. The volume of the sludge is 1 / 3 of the volume of the anaerobic reactor. Gradually increase the load of the anaerobic reactor, carry out sludge domestication, control the temperature at 35°C, and start-up process takes 35 days;

[0043] (2) Inject the leachate of the waste incineration plant into the adjustment tank by the lift pump, and after stirring evenly, adjust the pH to 8.0;

[0044] (3) Inject the leachate in the adjustment tank into the pre-acidification tank for pre-acidification treatment for 8 hours;

[0045] (4) Anaerobic fermentation: The leachate after pre-acidification treatment is injected into the biogas lifting reactor by a circulating water pump, and anae...

Embodiment 3

[0050] Embodiment three: a kind of leachate treatment method of domestic waste incineration plant, comprising the following treatment process:

[0051] (1) Start-up of the anaerobic reactor: the biogas lifting reactor is used as the anaerobic reactor, and the biogas lifting reactor is first inoculated with sludge. The volume of the sludge is 2 / 5 of the volume of the anaerobic reactor. Gradually increase the load of the anaerobic reactor, carry out sludge domestication, control the temperature at 34°C, and start-up process takes 32 days;

[0052] (2) Inject the leachate of the waste incineration plant into the adjustment tank by the lifting pump, and after stirring evenly, adjust the pH to 7.0;

[0053] (3) Inject the leachate in the adjustment tank into the pre-acidification tank for pre-acidification treatment for 7 hours;

[0054] (4) Anaerobic fermentation: The leachate after pre-acidification treatment is injected into the biogas lifting reactor by a circulating water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com