Method for preparing ethylene diamine from ethanolamine and ammonia serving as raw materials under hydrogen condition

A technology of ethanolamine and ethylenediamine, applied in the field of hydroxyethylpiperazine and hydroxyethylethylenediamine, aminoethylpiperazine, piperazine, and co-production of diethylenetriamine, can solve the problem of high energy consumption and equipment corrosion serious problems, to achieve the effect of improving selectivity, reducing reaction pressure and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

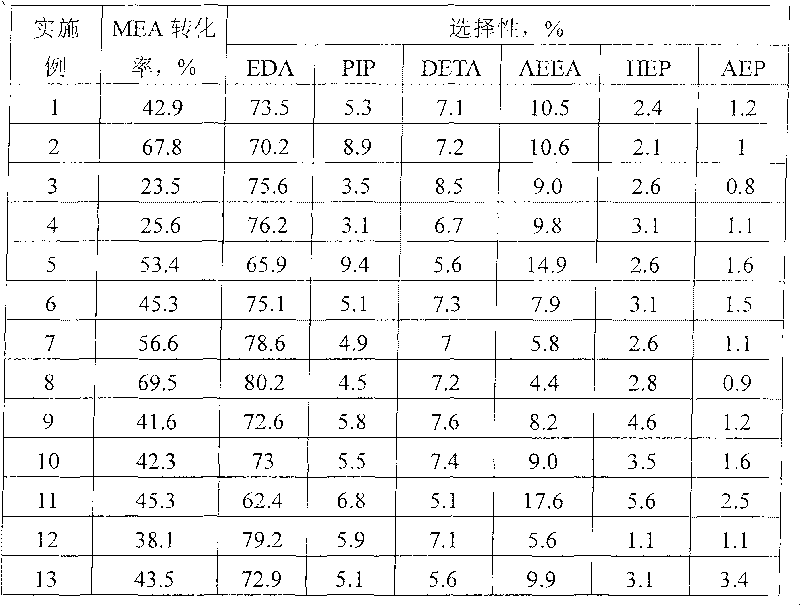

Examples

Embodiment 1

[0018] The catalyst used is Ni-Re-B / Al 2 o 3 . The weight composition of the catalyst is: Ni=15%, Re=1.6%, B=1.2%, and the rest is carrier Al 2 o 3 . The carrier adopts commercial Al 2 o 3 , and the catalyst active component Ni and additives Re and B were loaded on the carrier Al by conventional impregnation method 2 o 3 (Al 2 o 3 The particle size is 20-40 mesh). 8.0 grams (about 10ml) of the catalyst was activated by hydrogen before the reaction, and the activation conditions were: GHSV=2400h -1 , Atmospheric pressure, 375°C, reduction time 5 hours. Choose a fixed bed reactor. The reaction temperature is 155°C, the hydrogen pressure is 8.0MPa, the ammonia / ethanolamine molar ratio is 10, and the H 2 / ethanolamine molar ratio is 0.015 ethanolamine liquid space velocity is 0.5h -1 , the reaction time is 50h, sampling analysis. Samples were analyzed by gas chromatography, HP-15 capillary column, and FID detector. Dimethylformamide (DMFA) was used as internal stan...

Embodiment 2

[0020] The liquid space velocity of ethanolamine is 0.3h -1 , other conditions are identical with embodiment 1.

Embodiment 3

[0022] The liquid space velocity of ethanolamine is 0.7h -1 , other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com