Instrument composite magnet with magnetic temperature compensation

A magnetic temperature compensation and composite magnet technology, applied in the direction of magnets, magnetic objects, magnetic materials, etc., can solve the problems of no magnetic temperature compensation description, no magnetic temperature compensation effect, etc., to achieve improved magnetic utilization and high magnetic stability performance, reducing the effect of reluctance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step is to separately prepare the magnet powder and the magnetic temperature compensation part (iron-nickel alloy) powder separately, and the required particle size of the raw material is -150 mesh. The percentage by weight of the magnet powder is 24% of cobalt powder, 14% of nickel powder, 3% of copper powder, 17% of iron-aluminum alloy powder (1:1), 1% of niobium-iron alloy powder (1:1), and 41% of iron powder %; The percentage of powder for magnetic temperature compensation is 70% for iron powder and 30% for nickel powder. Mixing adopts a three-dimensional motion high-efficiency motion mixer, model GH-100, manufactured by Wenling Donghai Powder Equipment Manufacturing Factory. The mixing time is 100 minutes, and the mixing is required to be uniform.

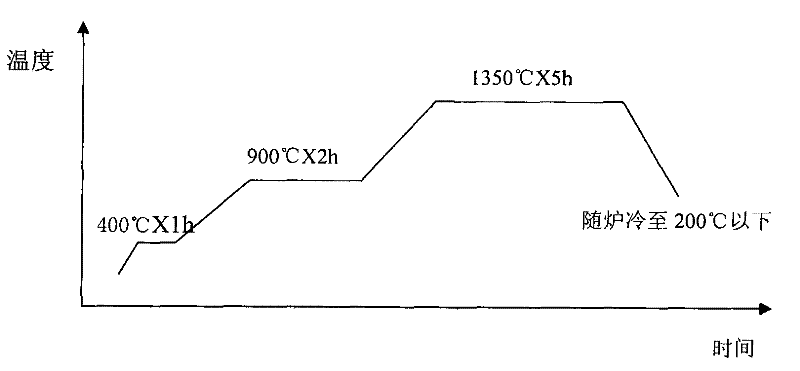

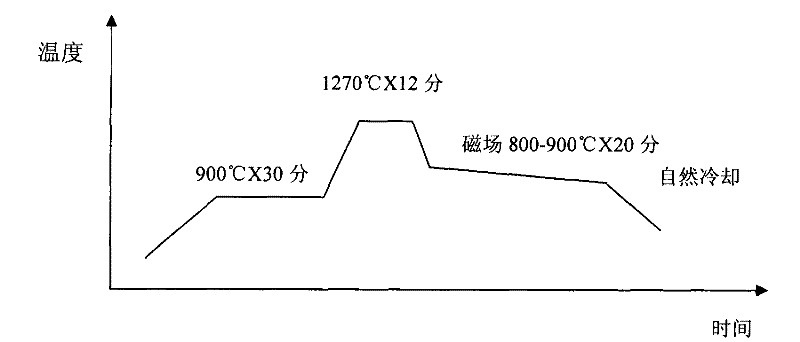

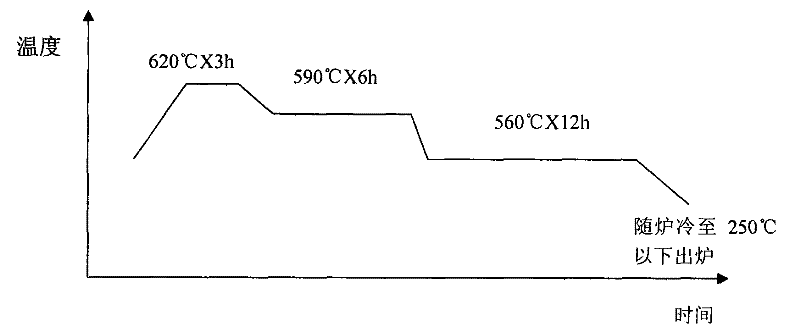

[0031] Second, the compression molding of the composite magnet, the equipment adopts a dry powder press, model Y41-400, the manufacturer Tianjin No. g magnet powder, and then add 2.8g of magnetic temperature ...

Embodiment 2

[0037] The magnet material is AlNiCo33 / 11, and the magnetic temperature compensation material is 1J30.

[0038] The manufacturing method is as follows:

[0039] The first step is to separately prepare the magnet powder and the magnetic temperature compensation part (iron-nickel alloy) powder separately, and the required particle size of the raw material is -150 mesh. The weight percentage of magnet powder is 35% of cobalt powder, 14% of nickel powder, 3.5% of copper powder, 15% of ferro-titanium (3:7), 15% of iron-aluminum alloy powder (1:1), ferroniobium powder (1:1) 2%, iron powder 15.5%; the percentage of magnetic temperature compensation powder is 70% iron powder and 30% nickel powder. Mixing adopts a three-dimensional motion high-efficiency motion mixer, model GH-100, manufactured by Wenling Donghai Powder Equipment Manufacturing Factory. The mixing time is 100 minutes, and the mixing is required to be uniform.

[0040] Second, the compression molding of the composite m...

Embodiment 3-12

[0046] Prepare product of the present invention as method and step described in embodiment 1, raw material is calculated according to the following table:

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com