Method for comprehensively utilizing waste gas and waste liquid in production of biurea

A biuret, waste liquid technology, applied in the preparation of urea derivatives, the preparation of organic compounds, alkali metal chlorides and other directions, can solve the problems of difficult recovery and purification process, high economic value of by-products, low added value, etc. Extensive, significant economic benefits and environmental protection significance, the effect of high concentration increase rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

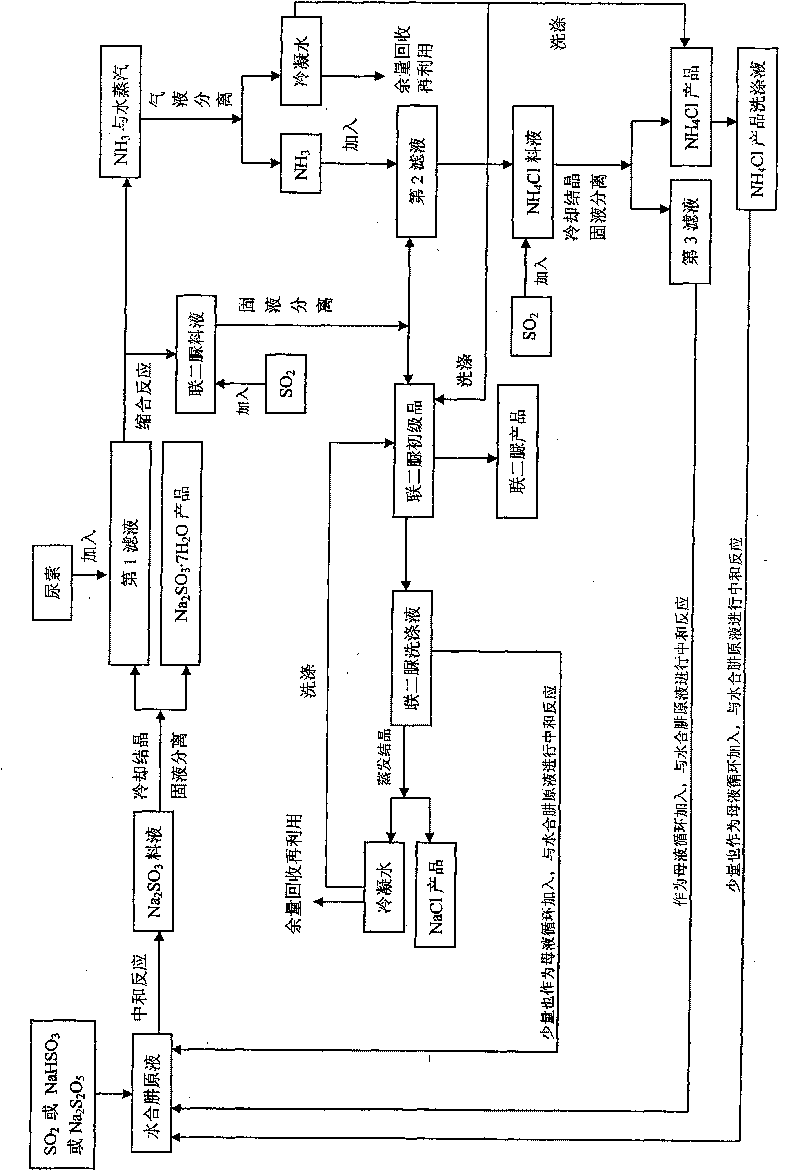

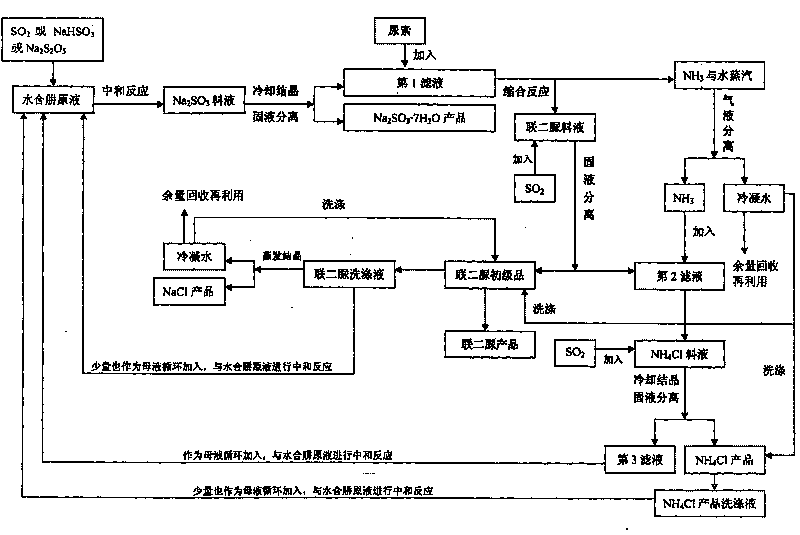

Image

Examples

Embodiment 1

[0027] Technical Features:

[0028] (1) According to the traditional process, urea and sodium hypochlorite are used to react to generate hydrazine hydrate stock solution, and the hydrazine hydrate stock solution is passed into SO 2 Gas, NaHSO 3 or Na 2 S 2 o 5 One of them, the pH value of the hydrazine hydrate solution is 6.0-7.0, the hydrazine hydrate solution is cooled and crystallized, and the solid-liquid separation is obtained to obtain Na 2 SO3 ·7H 2 O product and the 1st filtrate containing hydrazine hydrate;

[0029] NaOH, NaCO in hydrazine hydrate 3 with SO 2 Gas absorption reaction to form Na 2 SO 3 , The pH of the reaction end point is 6.0~7.0, and the reaction temperature is maintained at 30~55°C during the absorption process.

[0030] 2NaOH+SO 2 →Na 2 SO 3 +H 2 O ----------------(5)

[0031] Na 2 CO 3 +SO 2 →Na 2 SO 3 +CO 2 ↑-----------(6)

[0032] or hydrazine hydrate with NaHSO under stirring conditions 3 Neutralization reaction produces N...

Embodiment 2

[0059] Hydrazine hydrate and the third filtrate carry out neutralization reaction to generate Na 2 SO 3 Feed liquid, Na 2 SO 3 The feed liquid is cooled and crystallized, and Na is obtained after solid-liquid separation. 2 SO 3 7H 2 O product and 1st filtrate.

[0060] Add urea according to the amount of hydrazine hydrate in the first filtrate for condensation reaction, and the condensation reaction process produces NH 3 Pumped together with water vapor for gas-liquid separation, NH 3 Perform absorption reaction with the second filtrate, and remove a small amount of condensed water for the primary product of biurea, NH 4 Except for the washing water of Cl products, the rest are all recycled and comprehensively utilized.

[0061] A small amount of biurea primary product, NH 4 After the neutralization reaction of the Cl product washing solution and the hydrazine hydrate stock solution, it is used as a supplementary solution in the condensation reaction process.

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com