Method for preparing sodium sulfite by utilizing total alkali in hydrazine hydrate

A technology of sodium sulfite and hydrazine hydrate, applied in the field of hydrazine hydrate, can solve the problems of high added value of products, high cost, low energy consumption and the like, and achieve the effects of low price, low energy consumption and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

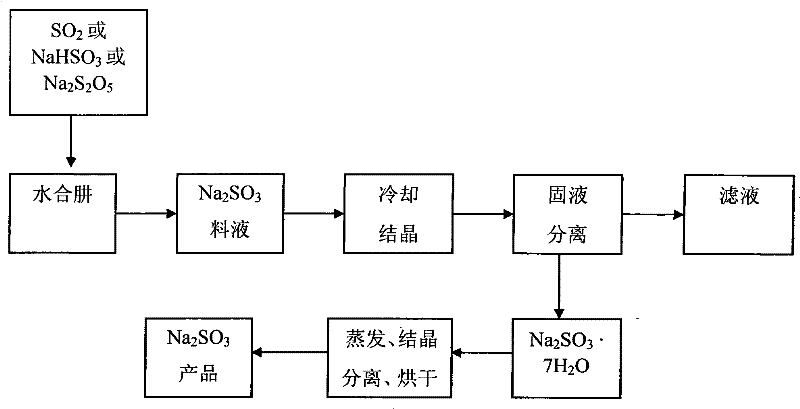

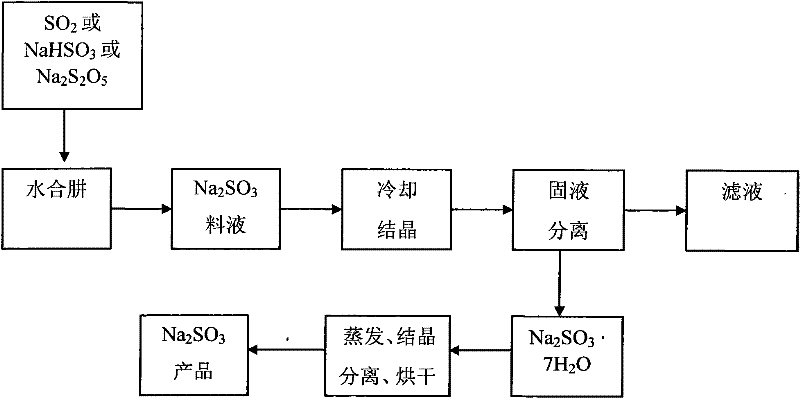

Image

Examples

Embodiment 1

[0030] Inject 1200ml of hydrazine hydrate solution in a 2000ml three-necked flask, its concentration of hydrazine hydrate is 3.9%, and its total alkalinity is 12%.2 The gas undergoes an absorption reaction, and the end point of the reaction is pH 6.5. Under the condition of stirring, move the three-necked flask into an enamel basin filled with ice water, cool the temperature to 15-20°C for 1 hour, and precipitate Na 2 SO 3 ·7H 2 O 435 grams, filtrate 975ml, hydrazine hydrate concentration 5.3% in the filtrate.

Embodiment 2

[0032] Inject 1200ml of hydrazine hydrate solution into a 2000ml three-necked flask with a hydrazine hydrate concentration of 3.9% and a total alkalinity of 12%. Under stirring conditions, sodium metabisulfite products are gradually added for reaction. In the basin, cool the temperature to 15-20°C for 1 hour to precipitate Na 2 SO 3 ·7H 2 O 420 grams, filtrate 1015ml, hydrazine hydrate concentration 5.1% in the filtrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com