Method for preparing ZnO nanometer powder by ultrasonic ball milling

A nano-powder and ultrasonic technology, which is applied in the preparation of ZnO nano-powder and the field of ultrasonic ball milling of ZnO nano-powder, can solve the problems of limiting the use range of ZnO nano-powder and affecting the nano-scale performance of ZnO nano-powder, and achieves cheap equipment. , low cost, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

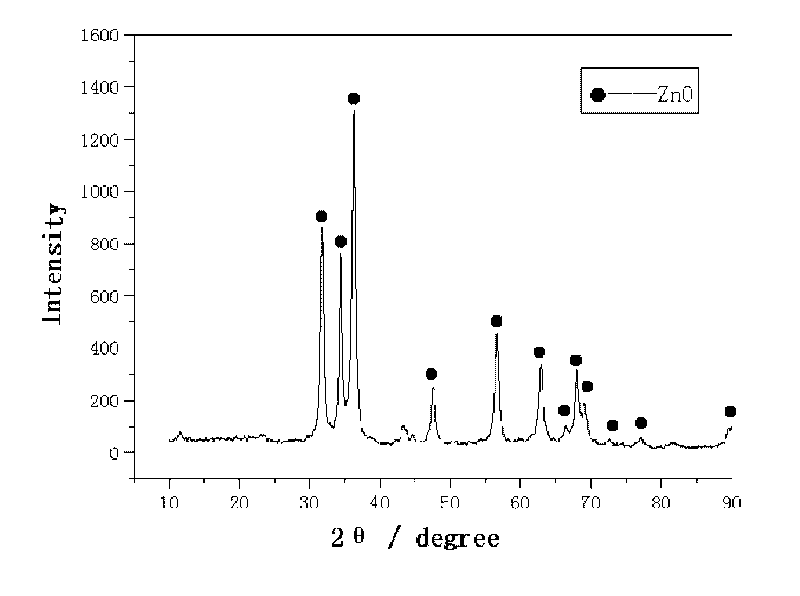

[0033] First, take 40 grams of metal zinc particles with an average particle size of 1 to 3 mm, 1200 grams of grinding balls with a diameter of 8 cm, and a ball-to-material ratio of 30:1. Ionized water is used as the ball milling fluid; then, the input frequency to the ultrasonic energy converter in the ball mill bucket is: 60KHz, and the power density is: 0.56W / cm 2 At the same time, start the ball mill, and control the speed to be 150r / min for ball milling; after 40 hours, sampling inspection, powder particle size has reached the process design requirements, stop ball milling; suction filtration, filter residue at 30 ℃, vacuum degree is 10 -1 Pa, drying, that is, to obtain pure ZnO nano powder. After testing, the obtained ZnO nano powder has a particle size of less than 100 nm and a purity of 100%, as shown in Table 1.

[0034] Table 1

[0035]

Embodiment 2

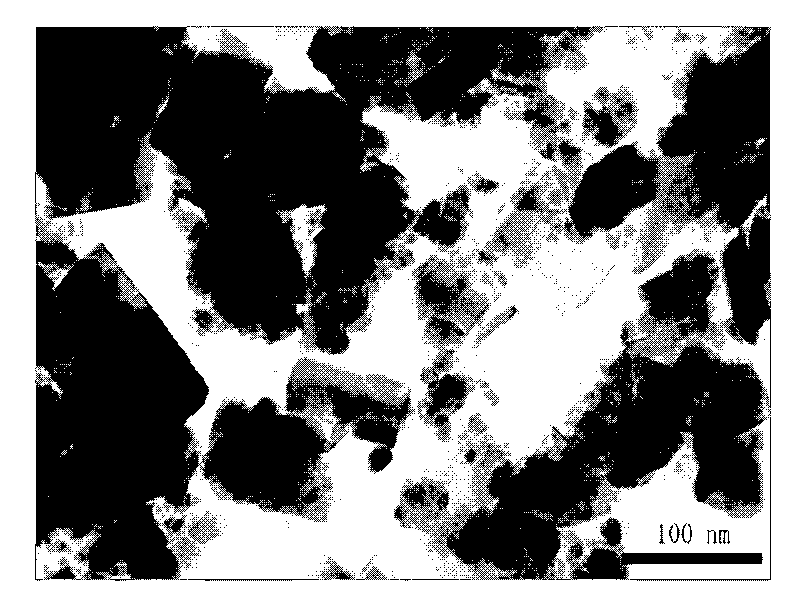

[0037] First, take 40 grams of metal zinc particles with a particle size of 1-3 mm, 1600 grams of grinding balls with a diameter of 10 cm, and a ball-to-material ratio of 40:1. Water is used as the ball mill liquid; then, the input frequency to the ultrasonic energy converter in the ball mill bucket is: 40KHz, and the power density is: 1.12W / cm 2 At the same time, start the ball mill, and control the speed to 250r / min for ball milling; after 25 hours, sampling inspection, the powder particle size has reached the process design requirements, stop the ball milling; suction filtration, filter residue at 40 ℃, vacuum degree is 10 -2 Pa, drying, that is, to obtain pure ZnO nano powder. After testing, the obtained ZnO nano powder has a particle size of less than 50nm and a purity of 100%, as shown in Table 2.

[0038] Table 2

[0039]

Embodiment 3

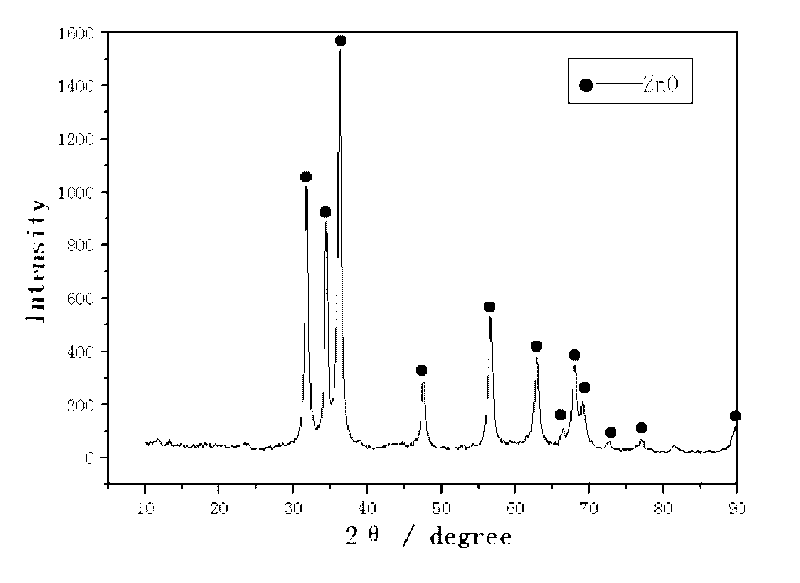

[0041] First, take 40 grams of metal zinc particles with a particle size of 1 to 3 mm, 2000 grams of grinding balls with a diameter of 12 cm, and a ball-to-material ratio of 50:1. Water is used as the ball milling fluid; then, the input frequency to the ultrasonic energy converter in the ball mill barrel is: 28KHz, and the power density is: 1.70W / cm 2At the same time, start the ball mill, and control the speed to be 350r / min for ball milling; after 20 hours, sampling inspection, the powder particle size has reached the process design requirements, stop the ball milling; suction filtration, filter residue at 40 ℃, vacuum degree is 10 -2 Pa, drying, that is, to obtain pure ZnO nano powder. After testing, the obtained ZnO nano powder has a particle size of about 20nm and a purity of 100%, as shown in Table 3.

[0042] table 3

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com