Device and method for deeply treating mine water for underground coal mine

A technology for advanced treatment and mine water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc., can solve hidden safety hazards, complex overall structure, time-consuming repair and maintenance work and other problems, to achieve the effect of good completeness and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

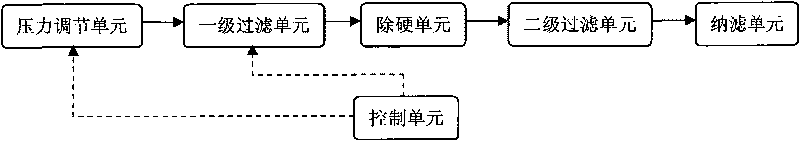

[0030] Such as figure 2 As shown, a coal mine underground mine water advanced treatment device, the device is arranged in the underground, including successively connected through pipelines: pressure adjustment unit 1-1, primary filter unit 2-2, dehardening unit 3-3, two stage filtration unit 4-4 and nanofiltration unit 5-5. It meets the advanced treatment of mine water with an inlet pressure of 0.7-2.0Mpa, and the treatment capacity is 1-2t / h.

[0031] The pressure regulating unit 1 - 1 mainly includes a filter 2 and a pressure reducing valve 3 . The feedwater inlet located at the front end of the pressure regulating unit 1-1 is connected to the filter 2, the pressure reducing valve 3, and the flow regulating valve 5 through pipelines in turn, and a shut-off valve 1, a pressure reducing valve 3 and A safety valve 4 is provided between the flow regulating valves 5, and the safety valve 4 is used to ensure safe pressure relief when the aforementioned pressure reducing valve fa...

Embodiment 2

[0041] A mine water advanced treatment device for underground coal mines, the specific scheme is the same as that of embodiment 1, the difference is that: figure 1 As shown, on the basis of the device described in Embodiment 1, the control unit 6-6 based on the hydraulic control system is added, and the pressure adjustment unit is improved; the number of primary filter units is increased, and the backwashing form is changed; the nanofiltration is changed Unit type and quantity. The added hydraulic control system realizes functions such as automatic start-stop and remote control of the equipment, which can meet the advanced treatment of mine water with an inlet water pressure of 2.0-3.5Mpa, with a processing capacity of 5t / h and a recovery rate of more than 70%. Such as image 3 As shown, the specific improvements are as follows:

[0042] The pressure regulating unit 1-1 is changed from the original one-stage decompression to the two-stage decompression, so that the incoming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com