Process for quickly and demicontinuously extracting bergenin

A technology of petgenin and extraction process, which is applied in the field of medicine, can solve the problems of large consumption of organic solvents, influence on competitiveness, long production cycle, etc., and achieve reduction of organic solvent consumption, cost and energy consumption, and shortened production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

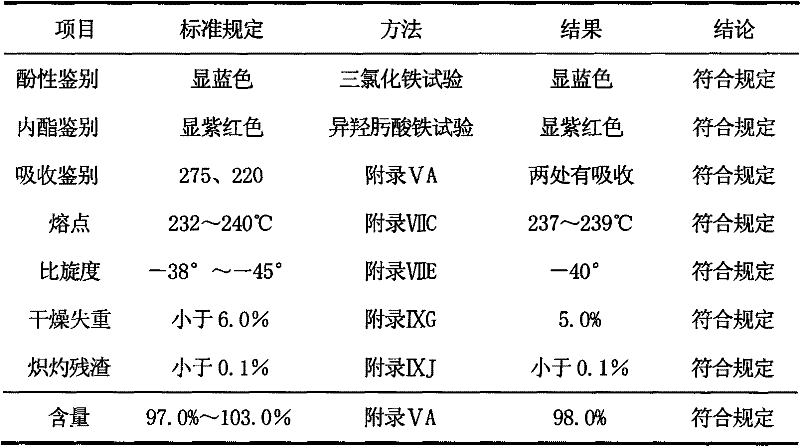

Image

Examples

Embodiment 1

[0020] 1) Pre-treatment: Remove the sundries and non-medicinal parts from the collected fresh medicinal materials, rinse them with water, drain off the free water on the surface, cut them into thin slices, and dry them at below 70°C to obtain the pure medicinal materials;

[0021] 2) Pulverization treatment: the clean medicinal materials are made into coarse powder by a circular pulverization process;

[0022] 3) Rapid semi-continuous extraction: take the medicinal material powder and place it in an airtight container, add 3 times the amount of solvent, infiltrate at 40°C for 1 hour, then use 40°C solvent to extract at a leaching speed of 20ml / kg-min until the extraction is complete;

[0023] 4) Concentration: Concentrate the extract under reduced pressure below 60°C to a density of 1.10-1.15 (60°C); adjust the pH to 2-3 with concentrated hydrochloric acid, stir, heat at about 70°C for 15 minutes, place, filter with Wash the filter cake with water until it is colorless, and dr...

Embodiment 2

[0026] 1) Pre-treatment: remove the sundries and non-medicinal parts of the collected fresh rock cabbage, rinse with water, drain off the free water on the surface, cut into thin slices, and dry below 60°C to obtain the clean medicinal material;

[0027] 2) Pulverization treatment: the clean medicinal materials are made into medium powder by a circular pulverization process;

[0028] 3) Rapid semi-continuous extraction: take the medicinal material powder and place it in a closed container, add 1.5 times the amount of solvent, infiltrate at 50°C for 0.5h, then use 50°C solvent to extract at a leaching speed of 35ml / kg-min until the extraction is complete;

[0029] 4) Concentration: Concentrate the extract under reduced pressure below 60°C to a density of 1.10-1.15 (60°C); adjust the pH to 2-3 with concentrated hydrochloric acid, stir, heat at about 70°C for 15 minutes, place, filter with Wash the filter cake with water until it is colorless, and dry it to obtain crude crystals ...

Embodiment 3

[0032] 1) Pre-treatment: remove the sundries and non-medicinal parts from the collected fresh astilbe medicinal materials, rinse them with water, drain the free surface water, cut them into thin slices, and dry them at below 60°C to obtain the pure medicinal materials;

[0033] 2) Pulverization treatment: the clean medicinal materials are made into medium powder by a circular pulverization process;

[0034] 3) Rapid semi-continuous extraction: take the medicinal material powder and place it in an airtight container, add 2 times the amount of solvent, infiltrate at 35°C for 2 hours, then use 35°C solvent to extract at a leaching speed of 20ml / kg-min until the extraction is complete;

[0035] 4) Concentration: Concentrate the extract under reduced pressure below 60°C to a density of 1.10-1.15 (60°C); adjust the pH to 2-3 with concentrated hydrochloric acid, stir, heat at about 70°C for 15 minutes, place, filter with Wash the filter cake with water until it is colorless, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com