System for trapping carbon dioxide in flue gas of coal-fired power plant and corresponding treatment method

A technology for carbon dioxide and coal-fired power plants, which is applied in the directions of direct carbon dioxide emission reduction, indirect carbon dioxide emission reduction, chemical instruments and methods, etc., can solve the problems of restricting the promotion and application of carbon dioxide emission reduction technology in coal-fired power plants, and achieves reduction of losses and emissions. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

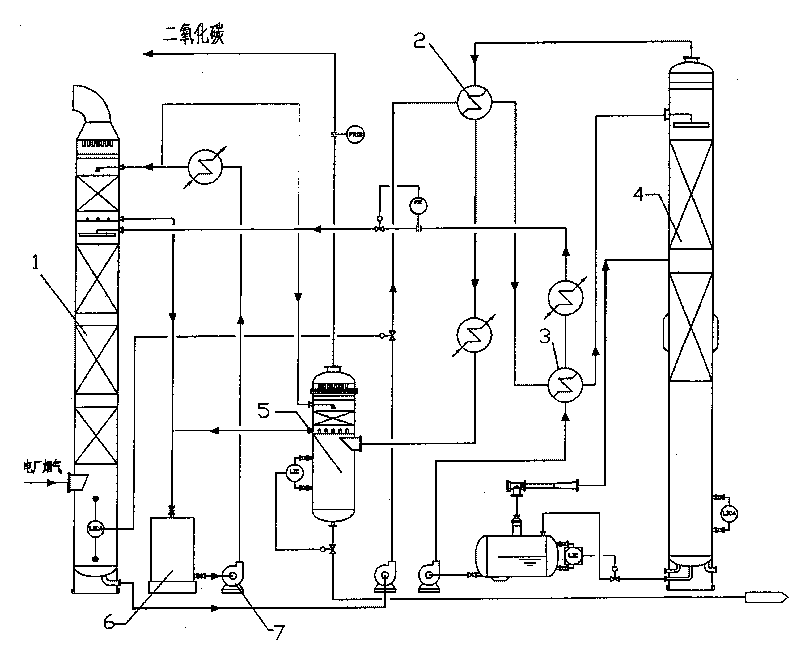

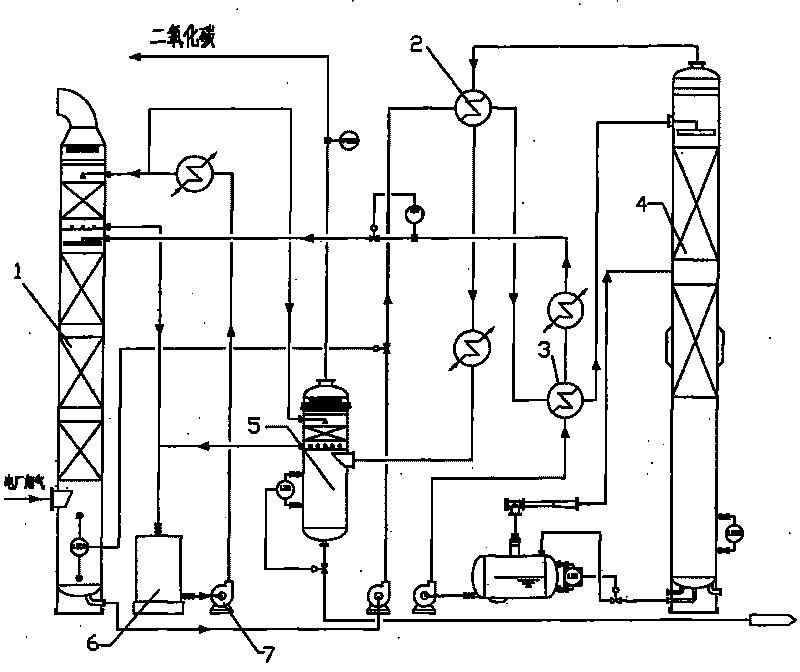

[0025] Such as figure 1 As shown, the carbon dioxide capture system in the flue gas of a coal-fired power plant of the present invention includes an absorption tower 1 and a regeneration tower 4, a regeneration gas condenser 2, a lean-rich liquid heat exchanger 3, a carbon dioxide separator 6 and a carbon dioxide compressor;

[0026] The flue gas outlet of the coal-fired power plant is boosted by the induced draft fan and connected to the bottom of the absorption tower 1. The flue gas moves from bottom to top and forms countercurrent contact with the ethanolamine solution for absorbing carbon dioxide that enters the tower from the upper part of the absorption tower 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com