Preparation method of gas purification material

A gas purification, solid technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., to achieve the effects of high reactivity, convenient operation, and fast chemical reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

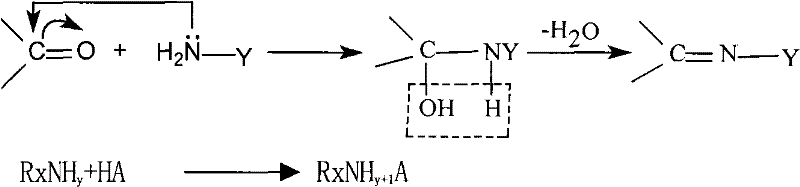

Method used

Image

Examples

Embodiment 1

[0018] With 2g of solid organic amine, adopt chemical coating method to make solid organic amine active component. Then, the solid organic amine active component was ground into 100-mesh powder, 183 g of aqueous pressure-sensitive adhesive solution was added, and fully stirred to form an active component emulsion. Burn 17g of 4mm columnar coal-based activated carbon at 105-110°C for 1 hour for pretreatment, then completely impregnate the activated carbon into the active component emulsion, and stir while adding. After being fully impregnated, filter out the activated carbon and dry it at 60°C.

Embodiment 2

[0020] 10g of solid organic amine was prepared into solid organic amine active component by chemical coating method. Then the solid organic amine active component was ground into 300-mesh powder, 183g of aqueous pressure-sensitive adhesive solution was added, and fully stirred to form an active component emulsion. Use a high-pressure spray gun to spray the active ingredient emulsion at 5 g / dm 2 Spray evenly on a 0.5cm thick sponge filter and dry at 70°C.

Embodiment 3

[0022] 10g of solid organic amine was prepared into solid organic amine active component by chemical coating method. Then the solid organic amine active component was ground into 300-mesh powder, 183g of aqueous pressure-sensitive adhesive solution was added, and fully stirred to form an active component emulsion. Use a high-pressure spray gun to spray the active ingredient emulsion at 2g / dm 2 Spray evenly on a 0.2cm thick synthetic fiber filter, and dry at 60°C. Fold the filter screen into a V-shaped structure to make a filter, increase the ventilation area per unit area of the filter structure, reduce wind resistance, and improve purification efficiency.

[0023] test

[0024] It is 120m that the V-shaped structure filter that embodiment 3 is made is packed into air volume 3 / h air purification device, put 25m 3 Tested in an airtight cabin (equivalent to an ordinary bedroom). The initial formaldehyde gas concentration is 1.00mg / m 3 , the hydrogen chloride gas concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com