Method for producing propylene glycol mono-methyl ether with energy conservation

A technology of propylene glycol methyl ether and methanol, applied in ether preparation, chemical industry, organic chemistry and other directions, can solve the problem of not considering the recovery of reaction heat, and achieve the effects of overcoming quality differences and service life, reducing energy consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Step 1. Purchasing and acceptance. A certain batch of pure methanol 100.125T with a water content of 0.043% is obtained, put into the catalyst preparation kettle 1, and 200kg of solid sodium methoxide catalyst is added through the funnel, so that the mass fraction of the catalyst is 0.2%;

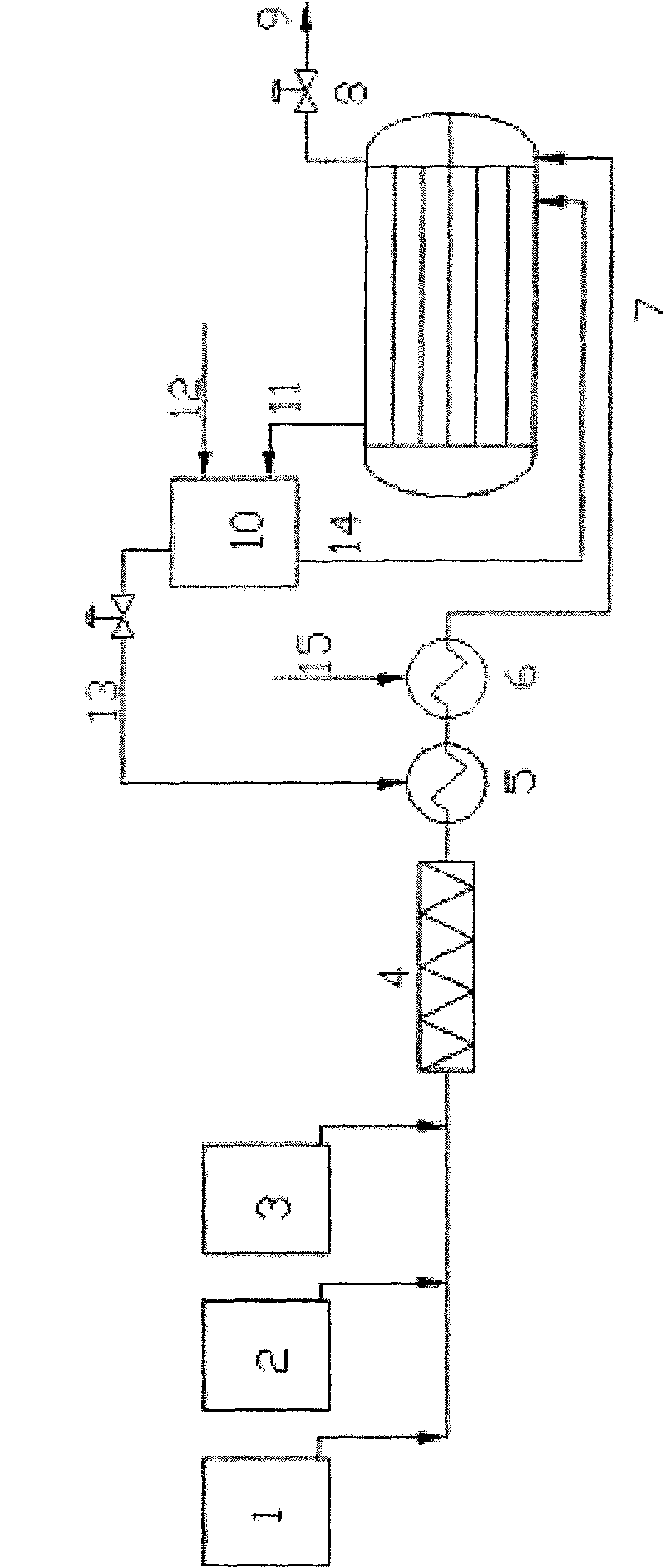

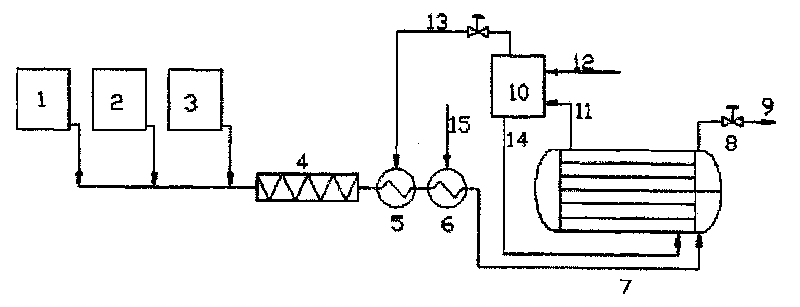

[0044] Step 2, the methanol with the catalyst dissolved, the reused methanol and propylene oxide are pumped into the static mixer 4 with a molar ratio of 2.5:2.5:1 for mixing, and then enter the preheater 5 by the impetus of the subsequent incoming raw materials , preheating the raw material to 120°C by using the steam generated after absorbing the heat of reaction described in the following step 4;

[0045] Step 3, the preheated mixed raw material enters the heater 6, and is heated to 135° C. by external steam 15 with a temperature of 180° C., so that the etherification reaction begins to take place;

[0046] Step 4. The pre-reacted material enters the tube side of the shell-and-tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com