Staphylococcus saprophyticus and application thereof in producing fermented segmental pork

A technology for staphylococcus saprophyticus and pork, applied in application, microorganism-based methods, bacteria, etc., can solve the problems of large volume, unfavorable carrying, subsequent processing, long processing cycle, etc., and achieve easy packaging and carrying, smooth and delicate cut surface, and muscle textured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Screening, Identification and Preservation of Staphylococcus saprophyticus CGMCC 3475

[0027] MSA medium: peptone 10g, mannitol 10g, NaCl 25g, beef extract 1g, 1g / L phenol red solution 25mL, distilled water 1000mL, pH 7.4, 121°C for 15min. Solid medium is supplemented with 1.8% agar on the basis of liquid medium.

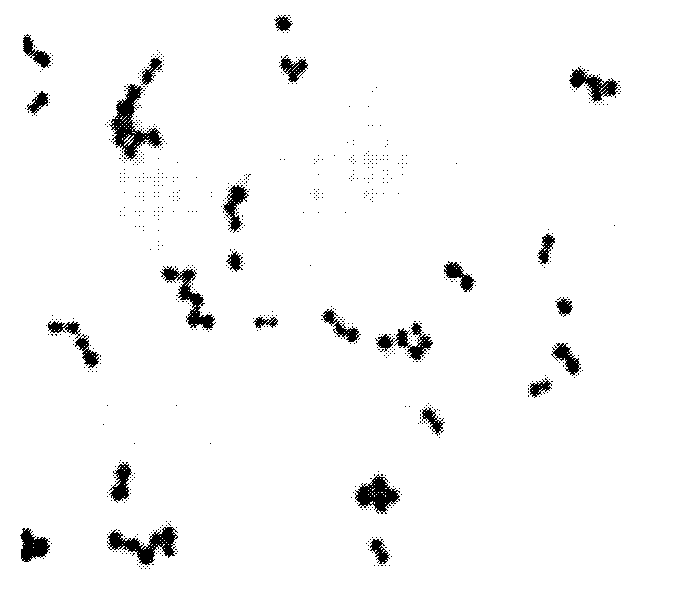

[0028] Isolation of strains: take the deep part (2.5cm) of ham with aseptic operation, cut it into pieces under aseptic conditions, place it in MSA liquid medium, cultivate it at 30°C for 48 hours, streak, pick a single colony, and continue to streak on the plate line until purification. Pure bacteria were subjected to Gram staining and cell morphology inspection, and Gram-positive bacteria were preserved for further inspection.

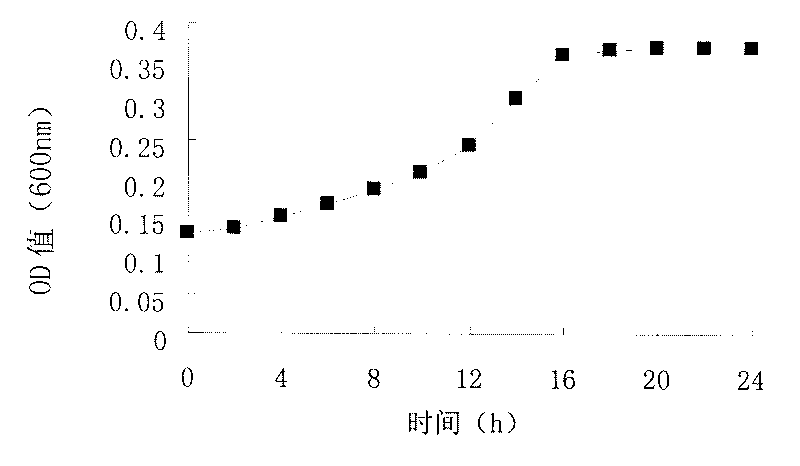

[0029] Primary screening of strains: Activate the isolated strains for two generations, adjust the number of bacteria, and make the concentration of bacteria reach 1×10 7 cfu / mL, respectively inoculated in the same am...

Embodiment 2

[0040] Embodiment 2: produce fermented pork with Staphylococcus saprophyticus CGMCC 3475

[0041] The specific features of the manufacturing process of the present invention's production of segmented fermented pork are further described below:

[0042] The processing technology mainly includes: cutting pork → pre-cooling → pickling → soaking and cleaning → drying → activation of bacteria → enrichment of bacteria → inoculation → fermentation → trimming → packaging.

[0043] The main points of operation are as follows:

[0044] (1) Pork cut into pieces: cut pork tenderloin with skin into pieces of 0.5-3Kg, preferably 1.0-1.5Kg.

[0045] (2) Pre-cooling: rapid cooling of pork at 5-8°C for 14-18 hours.

[0046] (3) Pickling: Pre-salt 1-3%, preferably 2% (mass percentage), temperature 2.0-5.0°C, humidity 75%-95%, pickle 2-4d; add salt 5 for the second time -7%, preferably 6% (mass percentage), temperature 2.5-4.5 ℃, humidity 65%-75%, pickle 7-10d.

[0047] (4) Cleaning and dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com