Technological method of parallel-connected sequencing batch dry type anaerobic digestion treatment of organic solid waste

A technology of organic solids and process methods, applied in biochemical equipment and methods, waste fuels, solid-phase fermentation bioreactors, etc., can solve the problems of difficult mixing of materials and easy acidification of fermentation materials, and achieve economical and concrete Operational feasibility, shortened start-up time, simple construction and construction facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: This example is a preferred example.

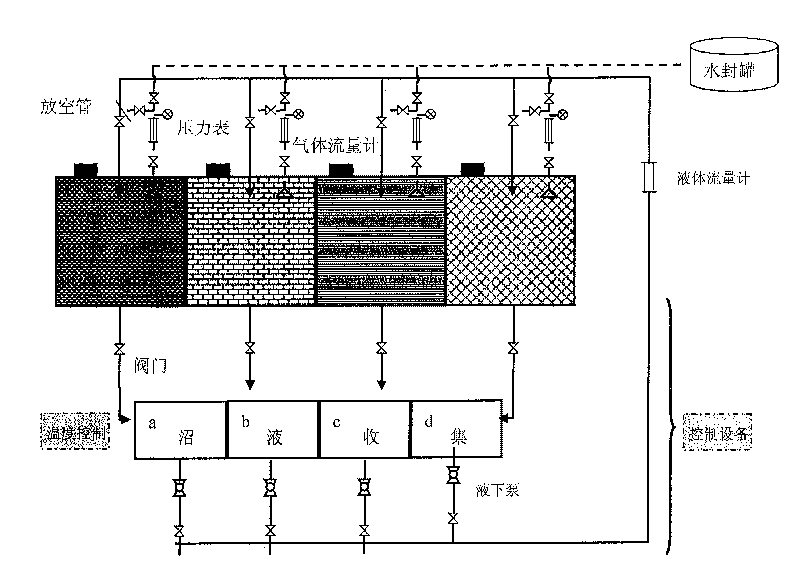

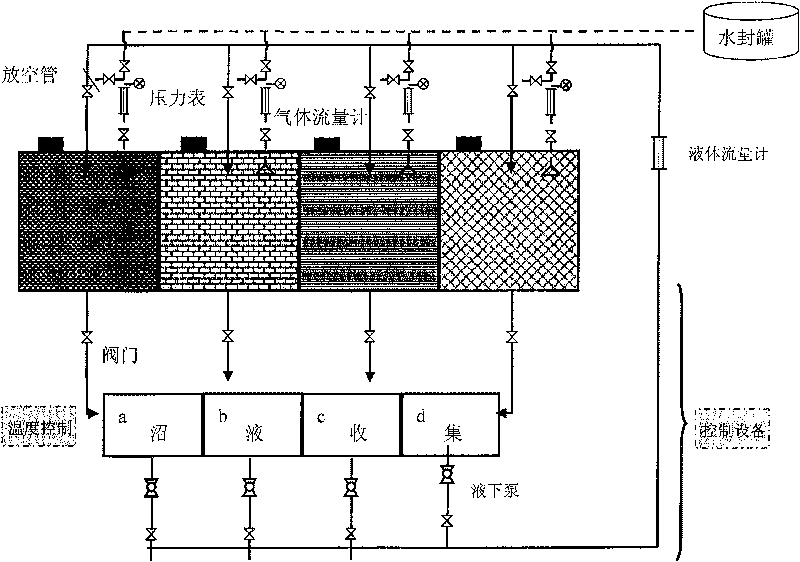

[0024] Such as figure 1 As shown, four reaction tanks are set up in this anaerobic digestion process, and the processing scale of each reaction tank is 10t. A biogas slurry collection tank is installed in the middle of the bottom of the reaction tank, and a single-flange perforated collection pipe is used for biogas slurry collection. The liquid enters the biogas slurry collection pond through the collection branch pipe and the main pipe. There is a heating coil in the biogas slurry collection pond, and the temperature can be adjusted according to the needs. The biogas slurry inlet and outlet pipes of the collection pond are equipped with valves, and the biogas slurry is collected and recharged according to actual needs. The temperature-adjusted biogas slurry is recharged through the submerged pump. If conditions permit, the controller can also be set according to the pH value and gas production rate of the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com