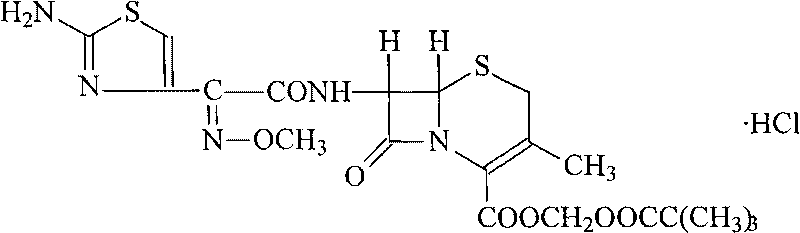

Cefetamet pivoxil hydrochloride submicron emulsion solid preparation and new application thereof

A technology of ceftazidime hydrochloride and metil submicroemulsion, which is applied in the field of medicine, can solve the problems of low dissolution rate, sticky granulation of raw materials, poor stability, etc., and achieve increased solubility, improved stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

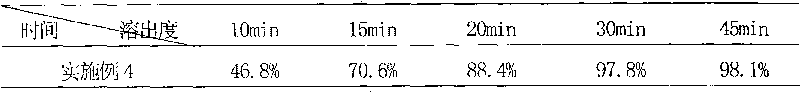

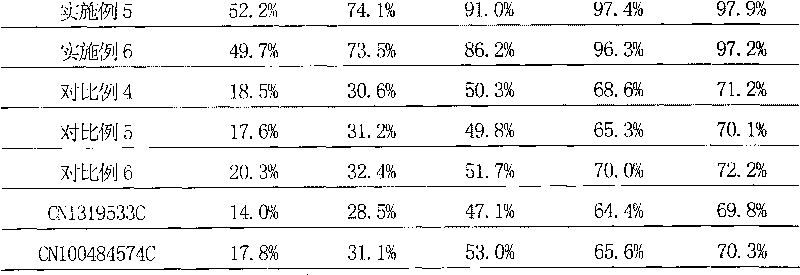

Examples

Embodiment 1

[0046] The preparation of embodiment 1 ceftamet pivoxil hydrochloride submicron emulsion particles

[0047]Add 1650g of cholesterol, 1025g of poloxamer 188 and 575g of sodium deoxycholate into 20L of water for injection, then add 250g of ceftazidime hydrochloride and mix evenly, heat and stir in a water bath at 80°C until it melts, and cut it with a tissue masher Stir for 15 minutes at a rotating speed of 13000r / min to obtain the first emulsion, then circulate and emulsify it through a high-pressure homogenizer for 5 times to obtain an emulsion, and then spray dry to obtain 3248g of submicron emulsion particles of ceftazidime hydrochloride, with a yield of 92.8%.

Embodiment 2

[0050] The preparation of embodiment 2 ceftamet pivoxil hydrochloride submicron emulsion particles

[0051] Add 500g of cholesterol, 325g of poloxamer 188 and 125g of sodium deoxycholate into 6000ml of water for injection, then add 125g of ceftazidime hydrochloride and mix well, heat and stir in a water bath at 90°C until it melts, and cut it with a tissue masher Stir for 20min, rotating speed 12000r / min, get first emulsion, then circulate emulsification through high-pressure homogenizer 5 times, get emulsified liquid, then freeze-dry in large plate, pulverize, obtain the submicroemulsion particle 988g of ceftamet pivoxil hydrochloride, yield 91.9 %.

Embodiment 3

[0054] The preparation of embodiment 3 ceftamet pivoxil hydrochloride submicron emulsion particles

[0055] Add 1250g of cholesterol, 750g of poloxamer 188 and 437.5g of sodium deoxycholate into 15,000ml of water for injection, then add 125g of ceftazidime hydrochloride and mix evenly, heat and stir in a water bath at 70°C until it melts, and cut it with a tissue masher. Cut and stir for 20min, rotating speed 15000r / min, to obtain the primary emulsion, and then circulate emulsification through a high-pressure homogenizer for 5 times to obtain an emulsion, then spray dry to obtain 2390g of submicron emulsion particles of ceftamet pivoxil hydrochloride, with a yield of 93.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com