Submerged arc welding process for low-temperature high-toughness niobium micro-alloy steel and welding wire thereof

A technology of micro-alloy steel and submerged arc welding, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of low-temperature toughness decrease of welded joints, difficult control of welding quality, and too far difference in toughness index, etc., and achieve fast welding speed , high safety margin, excellent low temperature impact and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

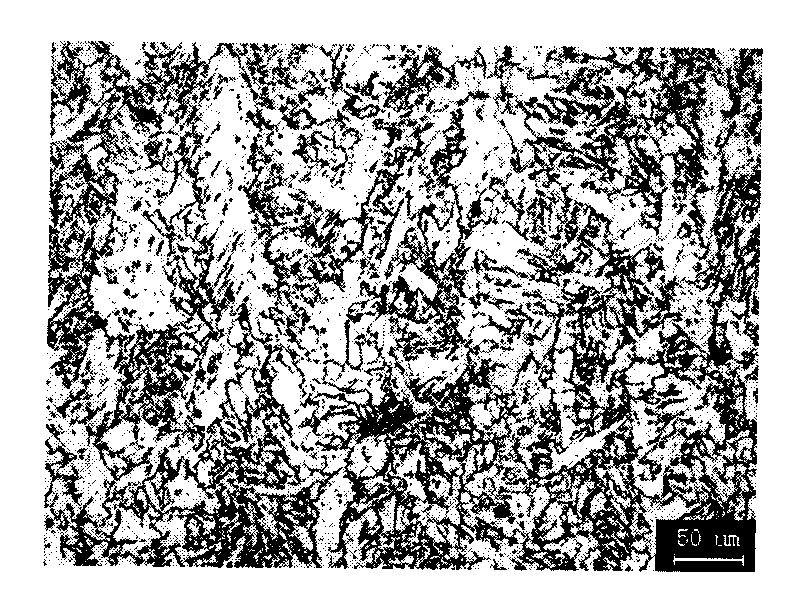

Embodiment 1

[0035] Substrate: Low-temperature high-toughness niobium microalloy steel plate produced by thermomechanical controlled rolling process (TMCP) + normalizing, the thickness combination is 30mm+30mm; the mechanical properties of the steel plate are: yield strength R p0.2 : 380MPa, tensile strength R m : 490MPa, Elongation A: 33%, -70℃CA KV Impact energy: 181J. The size of the test plate is 600mm×400mm×12mm; the submerged arc welding groove adopts X-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 6mm.

[0036] The results of welding heat simulation are shown in the table below:

[0037] Table 1

[0038] Line energy / (kJ / cm)

10

20

30

40

50

A KV (-70℃) / (J)

345 370

410 427

423 301

102 98

27 18

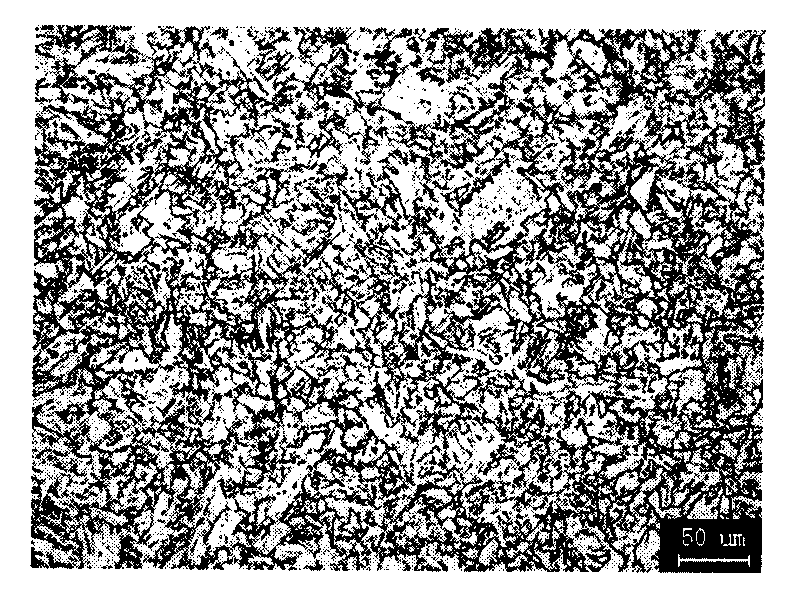

[0039] From the above thermal simulation results, it can be seen that the welding input energy is not more than 30kJ / cm, and the sample has high impact toughness. Select the following w...

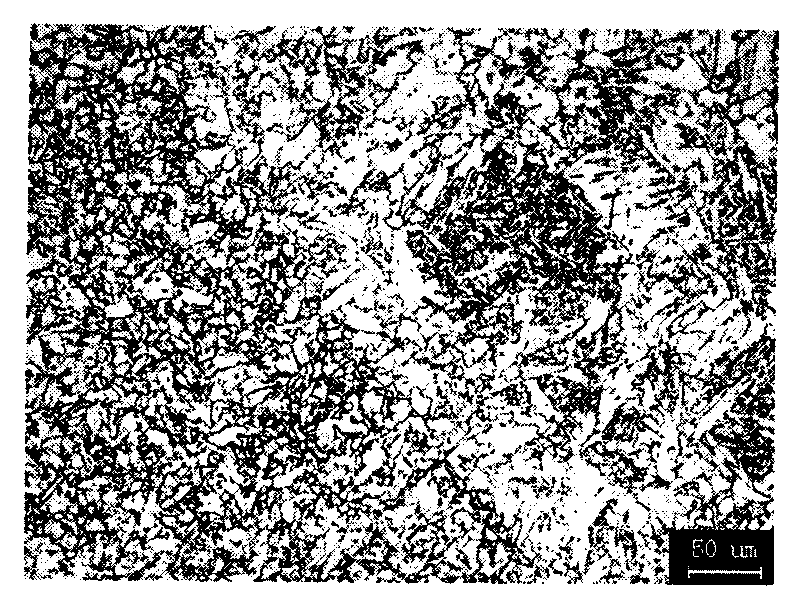

Embodiment 2

[0044]Substrate: Low-temperature high-toughness niobium microalloy steel plate produced by thermomechanical controlled rolling process (TMCP) + normalizing, the thickness combination is 52mm+52mm; the mechanical properties of the steel plate are: yield strength R p0.2 : 370MPa, tensile strength R m : 480Pa, Elongation A: 32%, -70℃CA KV Impact energy: 192J. The size of the test plate is 600mm×400mm×30mm; the submerged arc welding groove adopts X-shaped symmetrical groove, the groove angle is 60°, and the blunt edge is 6mm.

[0045] The results of welding heat simulation are shown in the table below:

[0046] Table 2

[0047] Line energy / (kJ / cm)

10

20

30

40

50

A KV (-70℃) / (J)

327 351

370 384

208 231

87 78

30 28

[0048] From the above thermal simulation results, it can be seen that the welding input energy is not more than 30kJ / cm, and the sample has high impact toughness. Select the following weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com