Preparation method of diammonium phosphate

A technology of diammonium phosphate and phosphoric acid, used in ammonium orthophosphate fertilizers, phosphates, phosphorus oxyacids, etc., can solve the problems of difficult to reach the design load, poor product performance, unsightly product appearance, etc., and achieve cleaning and maintenance. The effect of reduced workload, low production cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, the method for producing diammonium phosphate

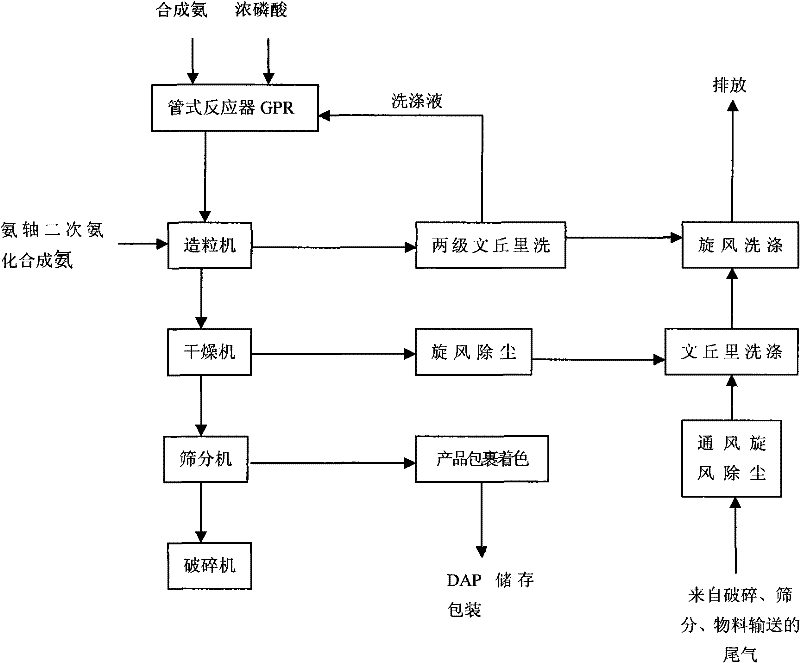

[0017] According to this embodiment figure 1 The process flow diagram shown is prepared, and the steps are as follows:

[0018] 1) the phosphoric acid (20 tons) of reaction raw material phosphoric acid gross mass 54% contains P 2 o 5 Add 40% fertilizer-grade industrial wet-process phosphoric acid and 78%-90% ammonia (10 tons) with a purity of 99.95% as the raw material for reaction to the tubular reactor of the granulator for rapid neutralization. Generate ammonium phosphate slurry;

[0019] 2) Spray the ammonium phosphate slurry prepared in step 1) into the rotary drum ammonification granulator through the nozzle of the tubular reactor, and then pass 1 to 3 tons of liquid into the material bed through the ammonia flow axis installed in the granulator. Ammonia, the ammonium phosphate slurry is further ammonified to a neutralization degree of 1.7-1.9, and granulated at the same time as the ammonification, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com