Method for coating hydrous zirconium oxide on surface of rutile type titanium dioxide

A titanium dioxide and rutile type technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of paint film yellowing, pulverization, harsh conditions, etc., and achieve simple process, less amount of zirconia, and good coating performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

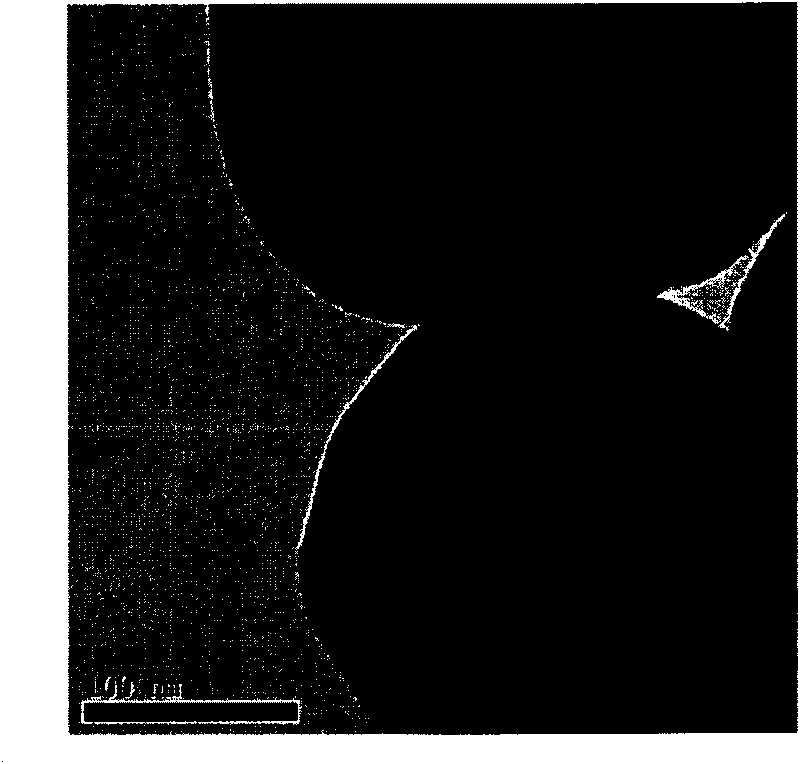

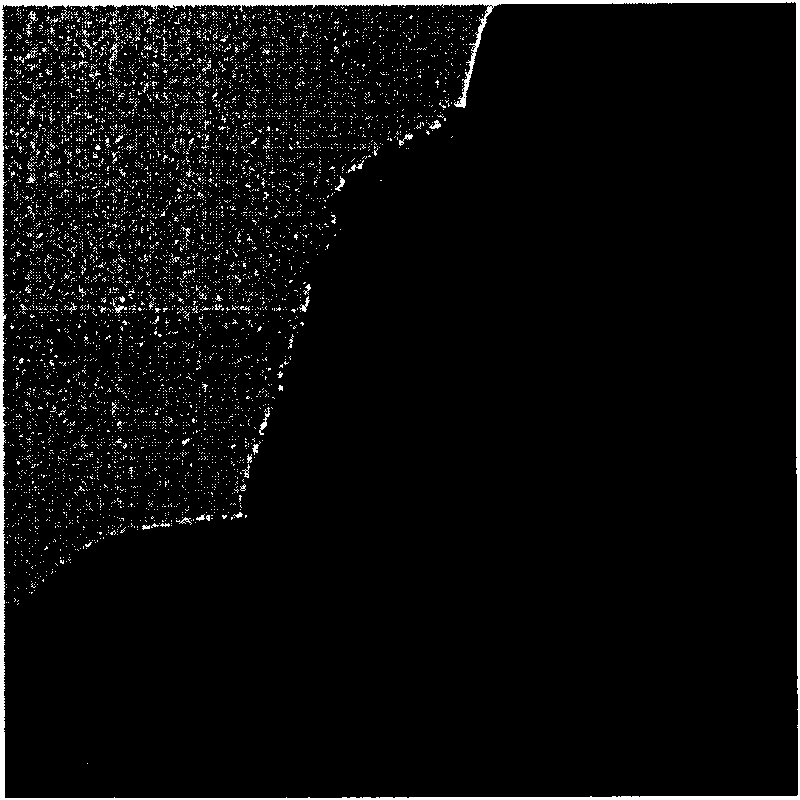

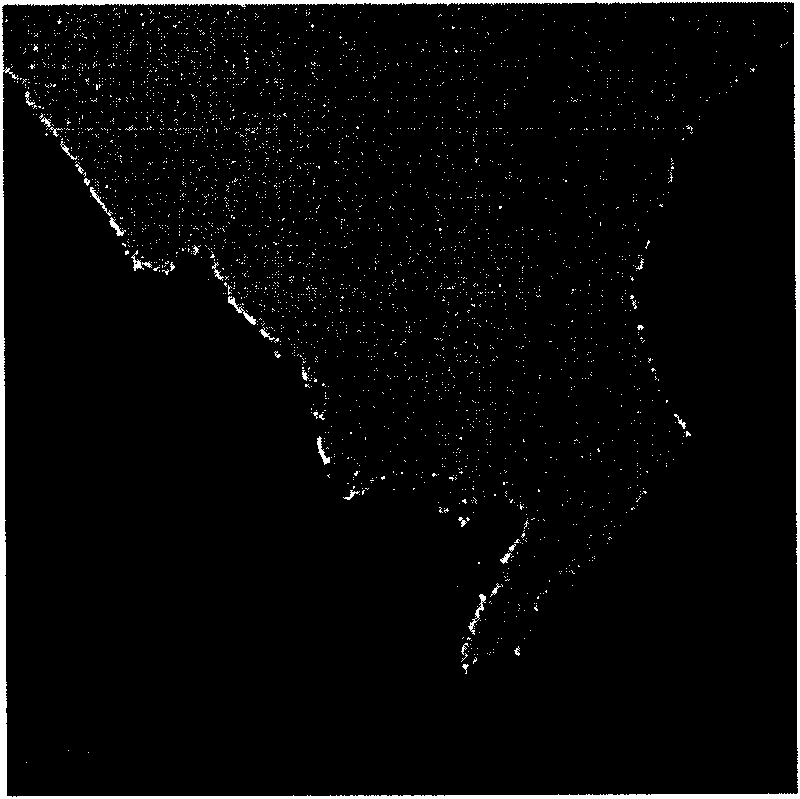

Image

Examples

Embodiment 1

[0019] Disperse 75g of titanium dioxide particles in 750ml of deionized water, add about 6ml of sodium hexametaphosphate solution with a concentration of 50g / L as a dispersant to make a suspension, and ultrasonically disperse for 30min. The titanium oxide particles are basically in a single particle dispersion state. Then, the TiO 2 The suspension was moved to a constant temperature water bath at 80° C., and the temperature was kept constant. Under the condition of rapid stirring, the pH was adjusted to 7 with 0.5 mol / L NaOH solution. Use two constant flow pumps to mix 200ml, 0.1mol / L ZrOCl 2 (make it contain ZrO 2 Weight is TiO 2 3%) solution and 120ml concentration of 1% mass fraction of H 2 SO 4 solution was added to the TiO 2 suspension, ZrOCl was kept during the experiment 2 The feeding rate of solution is constant (feeding time 3h), adjust H at any time 2 SO 4 The feed rate was increased to ensure that the pH of the solution was 7. After the feed was completed, i...

Embodiment 2

[0021] Disperse 75g of titanium dioxide particles in 750ml of deionized water, add about 6ml of sodium hexametaphosphate solution with a concentration of 50g / L as a dispersant to make a suspension, and ultrasonically disperse for 30min. The titanium oxide particles are basically in a single particle dispersion state. Then, the TiO 2 The suspension was moved to a constant temperature water bath at 80°C, and the temperature was kept constant. Under the condition of rapid stirring, the pH was adjusted to 9 with 0.5 mol / L NaOH solution. Use two constant flow pumps to mix 200ml, 0.1mol / L ZrOCl 2 (make it contain ZrO 2 Weight is TiO 2 3%) solution and 120ml concentration of 1% mass fraction of H 2 SO 4 solution was added to the TiO 2 suspension, ZrOCl was kept during the experiment 2 The feeding rate of solution is constant (feeding time 3h), adjust H at any time 2 SO 4 The feed rate is to ensure that the pH of the solution is 9. After the feed is completed, it is aged for 1...

Embodiment 3

[0023] Disperse 75g of titanium dioxide particles in 750ml of deionized water, add about 6ml of sodium hexametaphosphate solution with a concentration of 50g / L as a dispersant to make a suspension, and ultrasonically disperse for 30min. The titanium oxide particles are basically in a single particle dispersion state. Then, the TiO 2 The suspension was moved to a constant temperature water bath at 80° C., and the temperature was kept constant. Under the condition of rapid stirring, the pH was adjusted to 11 with 0.5 mol / L NaOH solution. Use two constant flow pumps to mix 200ml, 0.1mol / L ZrOCl 2 (make it contain ZrO 2 Weight is TiO 2 3%) solution and 120ml concentration of 1% mass fraction of H 2 SO 4 solution was added to the TiO 2 suspension, ZrOCl was kept during the experiment 2 The feeding rate of solution is constant (feeding time 3h), adjust H at any time 2 SO 4 The feed rate is to ensure that the pH of the solution is 11. After the feed is completed, it is aged f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com