Drip irrigation special fertilizer suitable for whole growth time of cut flower rose

A whole growth period, special fertilizer technology, applied in the application, nitrogen fertilizer, phosphate fertilizer and other directions, can solve the problems of high production cost of roses, lack of professional knowledge, low professional level, etc., to reduce nutrient loss, avoid dripper blockage, and increase yield. and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

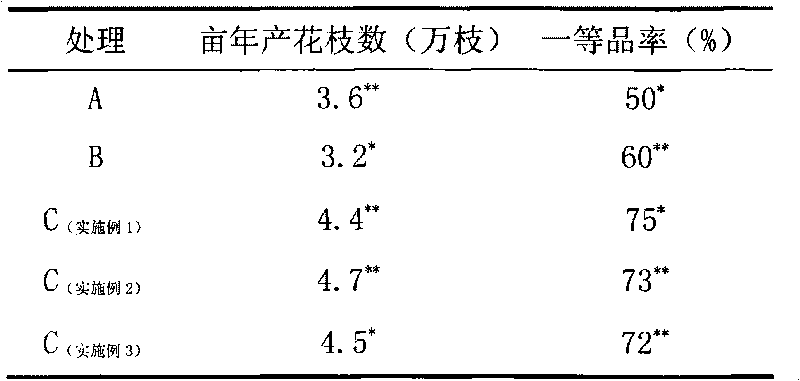

Examples

Embodiment 1

[0018] All raw materials in the special fertilizer of the present invention are calculated in parts by weight: potassium nitrate (KNO 3 )444.44 parts, monoammonium phosphate (NH 4 H 2 PO 4 ) 131.8 parts, urea (N 2 H 4 CO) 210.12 parts, magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O) 206.19 parts, boric acid (H 3 BO 3 ) 0.22 parts, EDTA chelated iron (EDTA-Fe) 4.61 parts, EDTA chelated copper (EDTA-Cu) 0.53 parts, EDTA chelated manganese (EDTA-Mn) 1.54 parts, sodium molybdate (Na 2 MoO 4 ) 0.012 parts, EDTA chelated zinc (EDTA-Zn) 0.53 parts. In order to ensure the water solubility of the special fertilizer and minimize impurities, the raw materials for the production of this special fertilizer are all agricultural grade or industrial grade elemental fertilizers with an insoluble content of less than 1%. The nitrate nitrogen content in the configured finished product is 6.04%, the ammonium nitrogen content is 1.59%, and the urea nitrogen content is 9.37%.

[0019] production proces...

Embodiment 2

[0026] All raw materials in the special fertilizer of the present invention are calculated in parts by weight: potassium nitrate (KNO 3 )442.32 parts, monoammonium phosphate (NH 4 H 2 PO 4 ) 115.72 parts, urea (N 2 H 4 CO) 225.79 parts, magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O) 210.19 parts, boric acid (H 3 BO 3 ) 0.17 parts, EDTA chelated iron (EDTA-Fe) 3.7 parts, EDTA chelated copper (EDTA-Cu) 0.43 parts, EDTA chelated manganese (EDTA-Mn) 1.23 parts, sodium molybdate (Na 2 MoO 4 ) 0.02 parts, EDTA chelated zinc (EDTA-Zn) 0.43 parts. In order to ensure the water solubility of the special fertilizer and minimize impurities, the raw materials for the production of this special fertilizer are all agricultural grade or industrial grade elemental fertilizers with an insoluble content of less than 1%. The nitrate nitrogen content in the configured finished product is 6.02%, the ammonium nitrogen content is 1.40%, and the urea nitrogen content is 10.45%.

[0027] The production pr...

Embodiment 3

[0029] All raw materials in the special fertilizer of the present invention are calculated in parts by weight: potassium nitrate (KNO 3 )466 parts, monoammonium phosphate (NH 4 H 2 PO 4 )148.17 parts, urea (N 2 H 4 CO) 173.7 parts, magnesium sulfate heptahydrate (MgSO 4 ·7H 2 O) 203.19 parts, boric acid (H 3 BO 3 ) 0.25 parts, EDTA chelated iron (EDTA-Fe) 5.54 parts, EDTA chelated copper (EDTA-Cu) 0.64 parts, EDTA chelated manganese (EDTA-Mn) 1.84 parts, sodium molybdate (Na 2 MoO 4 ) 0.03 parts, EDTA chelated zinc (EDTA-Zn) 0.64 parts. In order to ensure the water solubility of the special fertilizer and minimize impurities, the raw materials for the production of this special fertilizer are all agricultural grade or industrial grade elemental fertilizers with an insoluble content of less than 1%. The nitrate nitrogen content in the configured finished product is 6.34%, the ammonium nitrogen content is 1.78%, and the urea nitrogen content is 8.04%.

[0030] The production process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com