Method for preparing N-acetylamino acid

A technology of acetyl amino acid and amino acid, which is applied in the field of preparation of N-acetyl amino acid, can solve the problems of low yield of N-acetyl amino acid, difficult effective separation of sodium acetate, large consumption of reagents, etc., and achieves less reagent consumption and easy separation , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

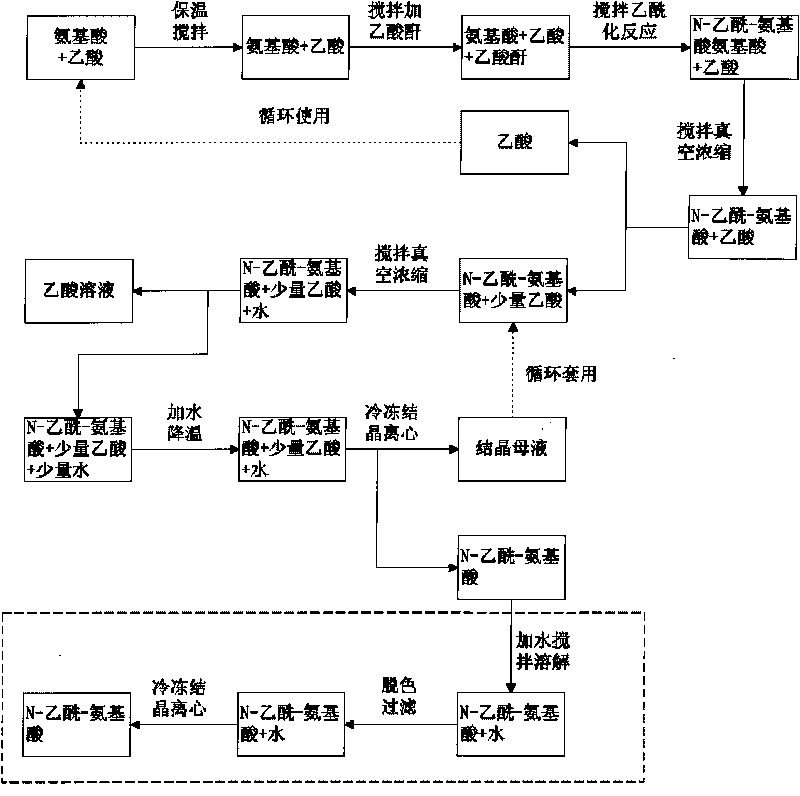

Image

Examples

Embodiment 1

[0015] A preparation method of N-acetylamino acid, which consists of the following steps: first, put 100g of D, L-methionine and 160ml of acetic acid into a dry 500ml Erlenmeyer flask and stir evenly, place the temperature in an electric heating mantle to raise the temperature to 50°C, and keep it warm for 1 hour, 70ml of acetic anhydride was added evenly, and the time of controlling feeding was 1.5 hours, and the temperature was 50° C.; after stirring and insulating for 1.5 hours, sampling was diluted to twice the original value, and monitored with ninhydrin (1% dehydrated alcohol). If the solution is colorless or basically colorless, it can be regarded as the end point; the temperature is controlled at 80°C, the vacuum degree is 0.076MPa, until the distilled liquid volume is about 200ml, and the remaining mass is kept at about 140g; then add 120ml of water, stir and cool down to 20°C, store in refrigerator at 5°C for 10 hours, then suction filter and dry. Using the same meth...

Embodiment 2

[0018] A preparation method of N-acetyl amino acid, which consists of the following steps: first, put 100g of D, L-methionine and 170ml of acetic acid into a dry 500ml Erlenmeyer flask and stir evenly, place the temperature in an electric heating mantle to raise the temperature to 55°C, and keep it warm for 1 hour; 72ml of acetic anhydride was evenly added dropwise, and the controlled feeding time was 3 hours, and the temperature was 55°C; after 1.5 hours of insulation, the sample was diluted to twice the original value, and was monitored with ninhydrin (1% dehydrated alcohol). The colorless or almost colorless solution can be regarded as the end point; once concentrated: the temperature is controlled at 75°C, the vacuum degree is 0.08MPa, the volume of the distilled liquid is about 220ml, and the remaining mass is kept at about 135g; after applying the mother liquor, the second Sub-concentration: the required time is 1 hour, the temperature is controlled below 80°C, the vacuum...

Embodiment 3

[0020] The method of the present invention in 3m 3 It is carried out in an open enamel stirred reactor. The specific process is as follows: First, add 500kg D, L-methionine and recovered 1100L acetic acid into the reactor and stir evenly, the temperature is controlled at 45-60°C, and the jacket is kept warm for 1 hour; at this time, 380L of acetic anhydride is added, and the control time is 5 Hours, the temperature is 50 ℃; keep warm for 3 hours. Concentrate at a vacuum of 0.08MPa and control the temperature at 75°C until the distilled liquid is about 1150L; continue to concentrate after applying the mother liquor: control the temperature below 80°C and vacuum at 0.075-0.08MPa until the distilled liquid is About 750L; finally add 1000L of water, stir and cool down to 20°C, pass through frozen brine to cool down to 5°C, keep warm for 6 hours, precipitate crystals, and filter with suction. The average recovery rate of five batches of continuous application of the mother liquor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com