Preparation method of sanitary ware with super-hydrophobicity surface

A technology of super-hydrophobicity and sanitary ware, which is applied in the field of surface modification of polymer materials and polymer-based sanitary ware materials, can solve the problems of easy dirtying, short service life, and difficult to clean, and achieves simple production process and low production cost. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Under the processing conditions of hot pressing temperature of 190°C, hot pressing time of 10min and hot pressing pressure of 10MPa; cold pressing temperature of room temperature, cold pressing time of 10min and cold pressing pressure of 10MPa, the injection molding grade ultra-high molecular weight polyethylene The pellets are processed into plastic sheets of a certain size; then, under the condition of 120°C, using the excellent ductility of ultra-high molecular weight polyethylene, the plastic panel for sanitary ware is prepared by vacuum forming; a certain amount of hot xylene solvent (temperature (greater than 120°C) quickly etch the surface of the plastic panel three times (each treatment time is about 30s); after the surface etching treatment, take an appropriate amount of aqueous solution to rinse for 3-5 minutes until the excess solution on the surface is rinsed away.

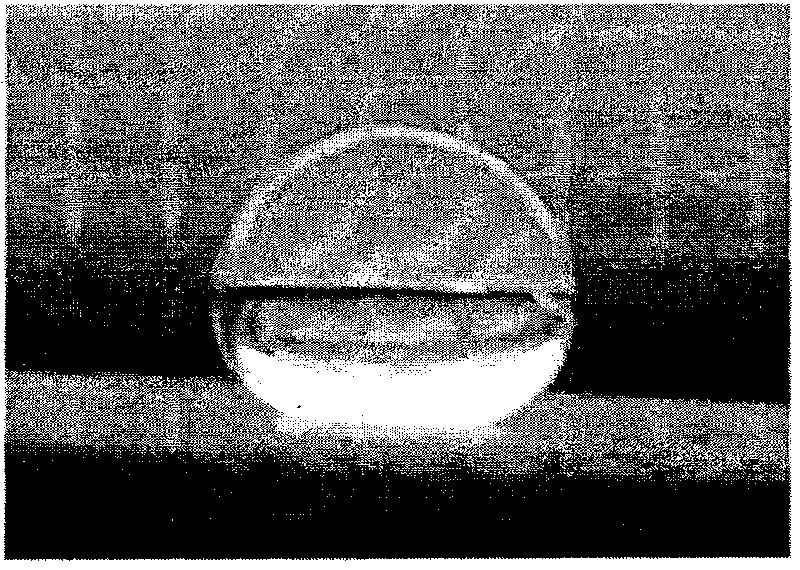

[0012] Attached from the manual figure 1 It can be seen that the ultra-high molecular weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com