Thermoplastic flame-retardant alloy and preparation method thereof

A thermoplastic and alloy technology, which is applied in the field of flame-retardant ABS resin, can solve the problems of no consideration of processability and physical performance requirements, and there is no flame-retardant ABS/polyester/copolyester alloy, etc., to make up for easy yellowing, good Mechanical properties, continuous effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

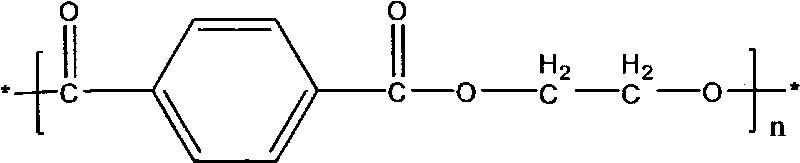

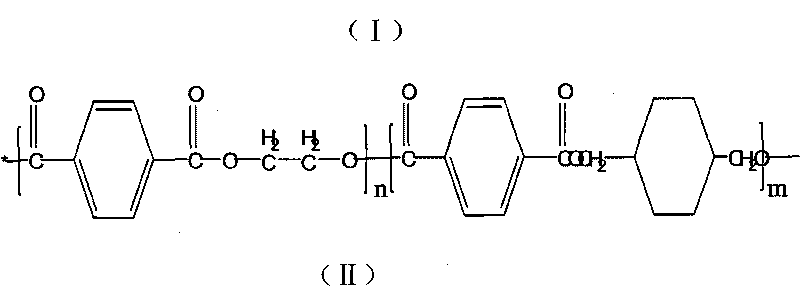

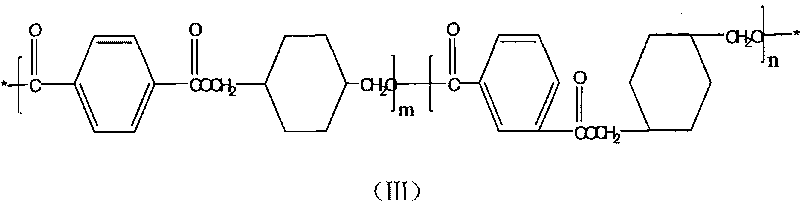

Method used

Image

Examples

Embodiment 1

[0041] Accurately weigh 100Kg of ABS resin, 40Kg of PET, 20Kg of tetrabromobisphenol A, 10Kg of CPE, 9Kg of antimony trioxide powder, tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionic acid] Pentaerythritol ester (anti-photothermal oxidant) 1Kg, vinylbisstearamide 0.8Kg, anti-dripping agent perfluoropolyethylene 0.5Kg. The novel thermoplastic flame-retardant alloy of the present invention is obtained through thorough mixing by a high-speed mixer, and a method of melt blending and one-step extrusion using a co-rotating twin-screw extruder. The physical properties of the obtained material are (ISO standard): IZOD notched impact strength 25KJ / m 2 , Bending strength 66MPa; Gloss (60-degree incident angle): 94.5; Flame-retardant grade (UL94): 1.5mm V-0.

Embodiment 2

[0043] Accurately weigh 100Kg of ABS resin, 30Kg of PET, 15Kg of PETG, 15Kg of tetrabromobisphenol A, 15Kg of CPE, 5Kg of antimony trioxide powder, tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxy Phenyl)propionic acid]pentaerythritol ester (anti-photothermal oxidant) 1Kg, vinylbisstearamide 0.3Kg, perfluoropolyethylene 0.8Kg. The novel thermoplastic flame-retardant alloy of the present invention is obtained through thorough mixing by a high-speed mixer, and a method of melt blending and one-step extrusion using a co-rotating twin-screw extruder. The physical properties of the obtained material are (ISO standard): IZOD notched impact strength 28KJ / m 2 , Bending strength 64MPa; Gloss (60-degree incident angle): 92; Flame-retardant grade (UL94): 1.5mm V-0.

Embodiment 3

[0045] Accurately weigh 100Kg of ABS resin, 25Kg of PETG, 25Kg of PCTG, 10Kg of tetrabromobisphenol A, 5Kg of brominated epoxy, 8Kg of CPE, 3Kg of antimony trioxide powder, tetrakis[β-(3',5'-di-tert-butyl Base-4'-hydroxyphenyl)propionic acid]pentaerythritol ester (anti-photothermal oxidant) 0.5Kg, vinylbisstearamide 2Kg, perfluoroethylene 0.5Kg. The novel thermoplastic flame-retardant alloy of the present invention is obtained through thorough mixing by a high-speed mixer, and a method of melt blending and one-step extrusion using a co-rotating twin-screw extruder. The performance of the obtained material is (ISO standard): IZOD notched impact strength 30KJ / m 2 , Bending strength 63MPa; Gloss (60-degree incident angle): 89; Flame-retardant grade (UL94): 1.5mm V-0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com