UV printing ink capable of being directly printed on UV coating and method for using printing ink

A coating and ink technology, applied in the post-processing of printing, printing, ink, etc., can solve the problems of many processes, low qualified rate of finished products, and time-consuming labor, so as to improve the yield rate, change the three-dimensional texture effect, and achieve continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

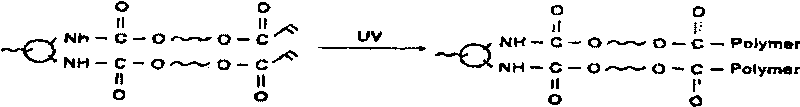

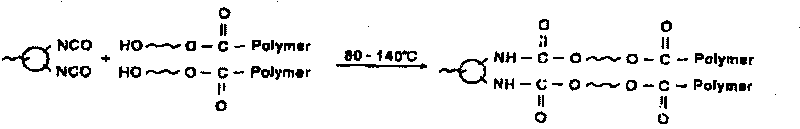

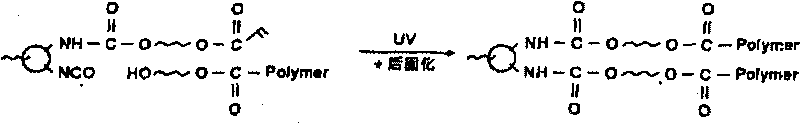

Method used

Image

Examples

Embodiment 1

[0050] UV ink composition:

[0051] SP series ink: 80Kg from Taiwan Yuyuanfu Company;

[0052] SG740 series resin (main component: C 3 h 8 N 2 O) Japan Seiko ink company 9Kg;

[0053] Adhesive: γ-Aminopropyltriethylsilane H 2 NCH 2 CH 2 CH 2 Si(OC 2 h 5 ) 35Kg

[0054] Curing agent: N-methylol-3,4,5,6-tetrahydrophthalimide, molecular formula: C 9 h 11 NO 3 1.5Kg;

[0055]

[0056] Diluent: N-butanone, toluene, 7-acetate mixture 8Kg

[0057] In this embodiment, the UV ink is mixed in advance according to the above ratio, and stirred evenly for later use.

[0058] The process scheme related to the present invention is: paint spraying→drying→UV spraying→drying→UV irradiation→removal→inspection→printing (UV ink)→drying→UV irradiation→inspection→post-processing→finished product packaging.

[0059] Process flow:

[0060] 1. Color paint spraying: On the UV coating of the mobile phone shell, use acrylic or polyurethane type paint, spray 2 coats to achieve the ...

Embodiment 2

[0070] UV ink composition:

[0071] SP series ink: Taiwan Yuyuanfu Company 83Kg;

[0072] SG740 series resin (main component: C 3 h 8 N 2 O) Japan Seiko ink company 9.2Kg;

[0073] Adhesive: g-(2,3-Glycidoxy)propyltrimethoxysilane CH 2 OCHCH 2 O(CH 2 ) 3 SI(OCH 3 ) 3 5.5Kg;

[0074] SG740 curing agent: N-methylol-3,4,5,6-tetrahydrophthalimide, molecular formula: C 9 h 11 NO 3 2.5Kg;

[0075]

[0076] Thinner: N-butanone, toluene, ethyl acetate 12Kg

[0077] Other than that, the process flow is the same.

[0078] The invention is used for the UV coating of consumer electronic products such as mobile phones, PHS, bluetooth earphones and MP3.

[0079] The achievable performance index of the product produced by the present invention is as follows:

[0080] Performance Indicator Type

achieve standard

testing method

Adhesion

≥4B

3M test tape, GB / T 9286-88

Adhesion

5B

3M Test Tape

pencil hardness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com