Method for producing needle coke by utilizing delay coking of coal tar

A technology of delayed coking and needle coke, which is applied in the direction of coking carbonaceous materials, coking ovens, petroleum industry, etc., can solve the problems of large investment and complicated process, and achieve the effect of shortening the processing process, low cost and widely used

Active Publication Date: 2010-06-09

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above method still requires a special coal tar raw material pretreatment device, the process is complicated and the investment is large

In addition, the above method is mainly to remove quinoline insolubles and impurities in coal tar, and when producing needle coke, some components with higher cracking reactivity and higher polymerization reactivity will also degrade the needle coke. The formation of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

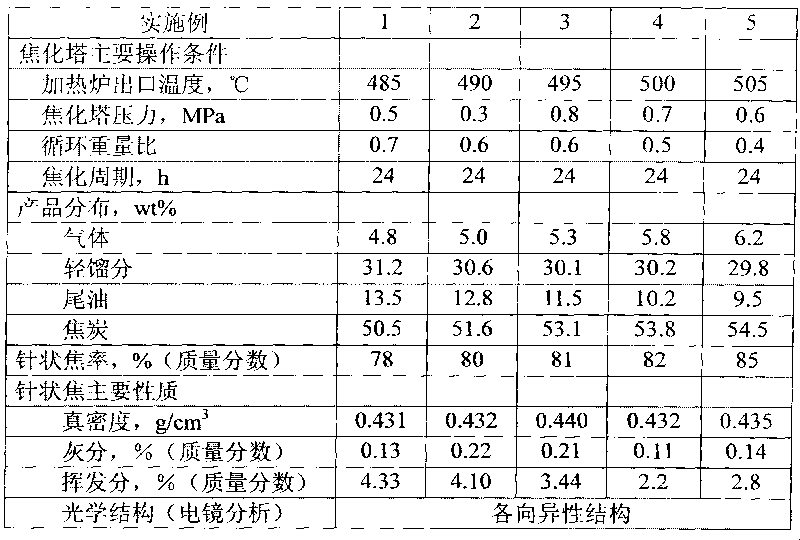

Embodiment 1-5

[0028] In the embodiment, all experiments use the same raw material oil, aiming to compare the effects under different operating conditions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

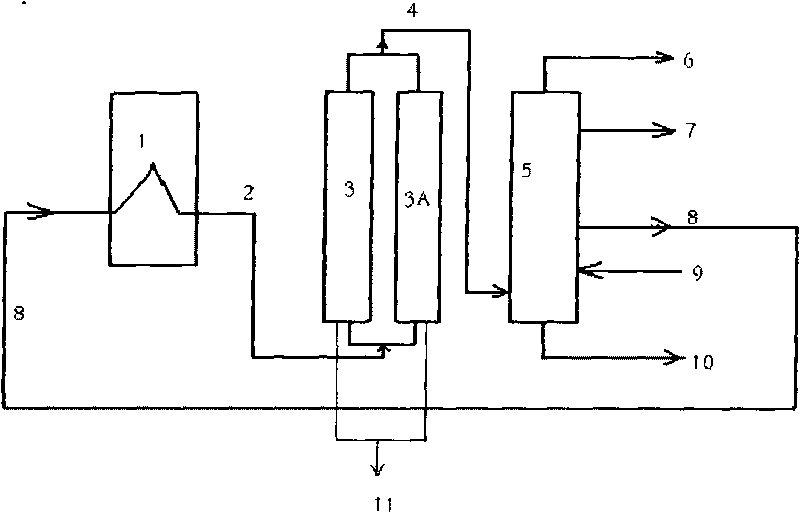

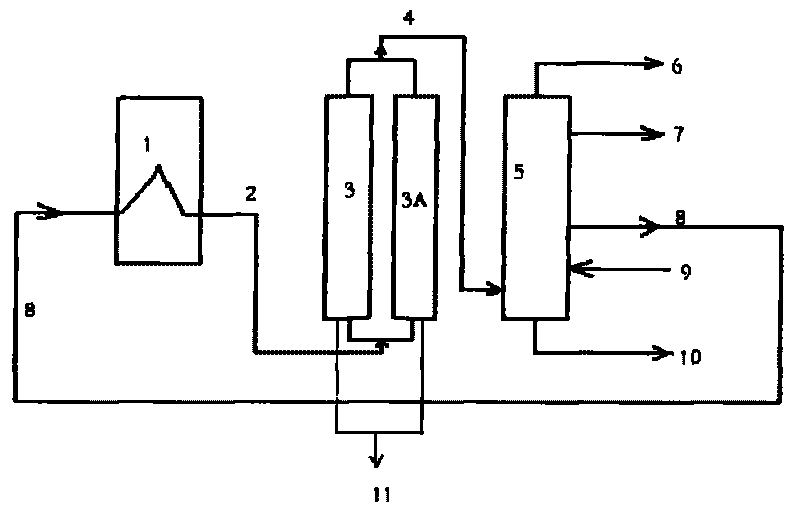

The invention discloses a method for producing needle coke by utilizing delay coking of coal tar. The method comprises the following steps of: putting fraction gasified tar into a coking fractionator, countercurrently contacting with high-temperature oil gas from a coking tower, carrying out heat exchange and eluting coke powder, and simultaneously separating to obtain light fraction, intermediate fraction and tail oil, wherein the intermediate fraction is used as a coking raw material to produce the needle coke with anisotropic optical structure under the process condition of being suitable for producing the needle coke. In the method, the separating treatment is carried out on the fraction gasified tar without an independent fractionator, and the high-temperature oil gas from the cokingtower is simultaneously separated in the coking fractionator, not only the flow is simple, the investment is saved, but also the light fraction and the tail oil which are not beneficial to producing the needle coke in the fraction gasified tar can be simultaneously separated out, and the obtained needle coke has high yield and good quality.

Description

technical field [0001] The invention belongs to a process method for preparing needle coke. Specifically, it is a method of producing needle coke by using a delayed coking process, and at the same time obtains light distillate oil as a by-product. Background technique [0002] Needle coke is the main raw material for producing high-power and ultra-high-power graphite electrodes, and its economic value is very high. The main method of producing needle coke is the delayed coking process. The most critical issue in the production of needle coke is to pretreat the raw material to remove the components and impurities in the raw material that are unfavorable to the production of needle coke. [0003] At present, the conventional raw materials suitable for the production of needle coke are heavy petroleum raw materials with high aromatic content, low colloid and asphaltene content, and low sulfur content, such as pyrolysis tar, catalytic cracking clarified oil, and extracted oil ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10B55/00

Inventor 张学萍任翠霞勾连忠巩济新初人庆石岩高翔朱文权

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com