Surface treatment method for C-C heating element

A surface treatment, heating element technology, applied in chemical instruments and methods, silicon compounds, coatings, etc., can solve the problems of life discount, easy peeling off of coatings, corrosion, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention promotes H 2 and SiCl 4 At an appropriate temperature, dense polysilicon is formed on the surface of the C-C heating element material, and then in a hydrogen environment, by adjusting the temperature, the polysilicon reacts with the C of the C-C heating element to form a SiC protective film to extend the life of the C-C heating element the goal of.

[0009] 2H 2 +SiCl 4 →Si+4HCl

[0010] Si+C→SiC

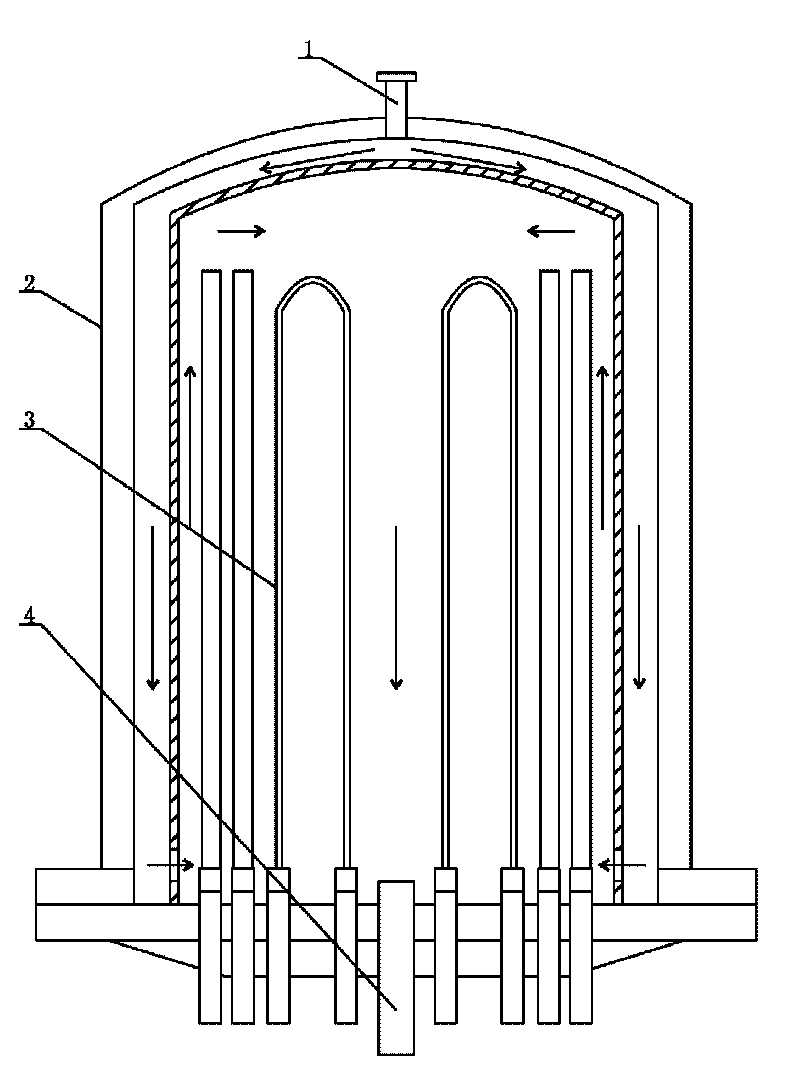

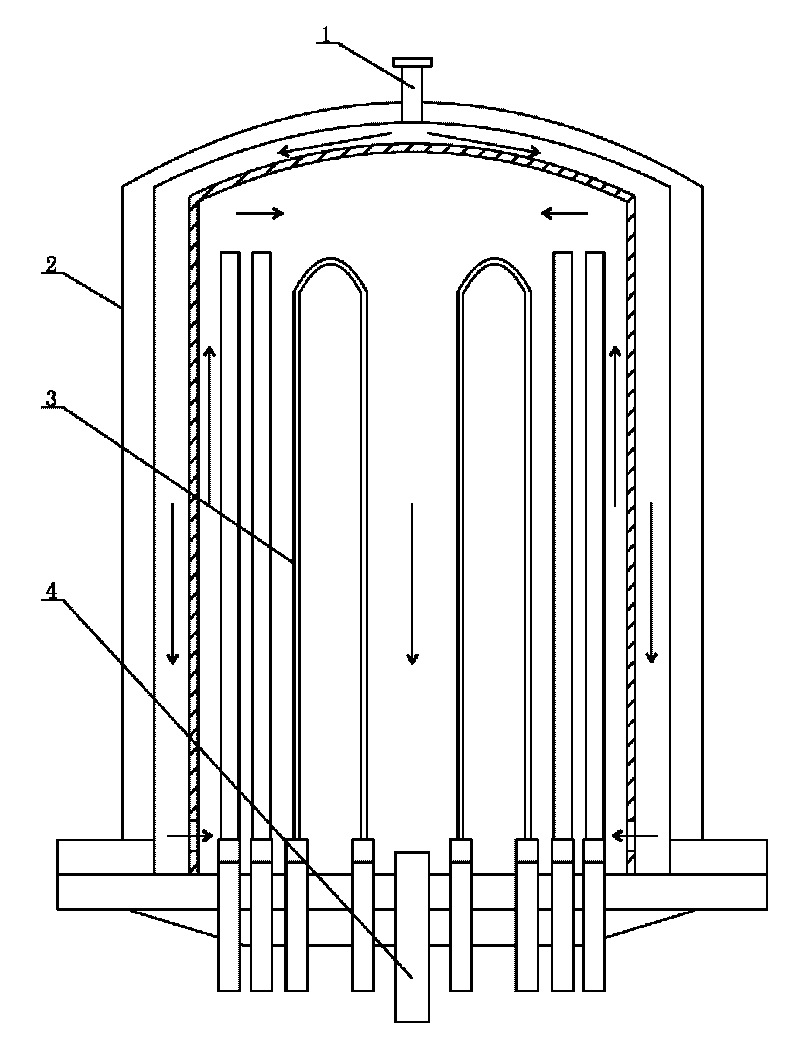

[0011] Such as figure 1 Among them, a method for surface treatment of a C-C heating element, the C-C heating element 3 is loaded in the furnace body 2 of the hydrogenation furnace, and the N 2 Replace the air in the furnace body 2, energize the C-C heating element 3, catch up with nitrogen and air-fire, and gradually raise the temperature to 800°C; use H from the process gas inlet 1 2 replace N 2 , heated to 1080-1200°C for 1 hour, and then passed into H according to a certain molar ratio of 10-20:1 2 with SiCl 4 Mixed gas, chemical vapor depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com