POSS-modified polypropylene melt-blown nonwoven fabric and preparation method thereof

A polypropylene melt-blown and non-woven fabric technology is applied in the field of non-woven fabrics to achieve the effects of soft hand feeling, low implementation cost and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

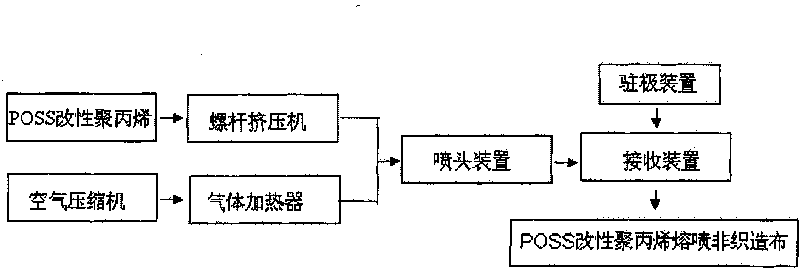

[0030] The preparation method of the POSS modified polypropylene melt-blown nonwoven fabric electret of the present invention's design, comprises the steps:

[0031] (1) For the preparation of polypropylene functional masterbatch, first pour POSS and polypropylene slices into a high-speed mixer and mix for 30 minutes, and then add the mixed raw materials into the twin-screw compounding extruder, at a temperature of 130°C Melt extrusion, cooling in a water bath, cutting into pellets to obtain POSS modified polypropylene functional chips.

[0032] (2) To manufacture melt-blown nonwovens, feed the polypropylene functional masterbatch directly into the screw extruder, melt and extrude it at 250-280°C, and then filter it through a melt filter and measure it with a metering pump. It is sprayed out from the spinneret hole of the melt-blown die head, and under the action of hot air blowing at 250-280 °C on both sides of the spinneret hole of the melt-blown die head, it can be made int...

Embodiment 1

[0041] The polypropylene slices are directly fed into the screw extruder, melted and extruded at 280 ° C, and then filtered through the melt filter and metered by the metering pump, and then input into the spinneret hole of the melt-blown die and ejected in the melt Under the action of hot air blowing at 280°C on both sides of the spinneret hole of the injection die head, the melt-blown nano-microfiber can be made. By adjusting the speed of the screw and the metering pump, the weight of the fiber web can reach 50g / m 2 , and strengthened into a pure polypropylene melt-blown nonwoven fabric by its own waste heat on the receiving device.

[0042] The longitudinal and transverse breaking strengths measured by YG065 electronic fabric strength tester are 30N / 5cm and 24N / 5cm respectively.

Embodiment 2

[0044] (1) Preparation of polypropylene functional masterbatch, first pour 3wt% octavinyl POSS and polypropylene chips into a high-speed mixer and mix for about 30 minutes, then add the mixed raw materials into a twin-screw compounding extruder at 130 Melt and extrude at a temperature of about ℃, cool in a water bath, cut into pellets, and obtain polypropylene functional masterbatches.

[0045] (2) To manufacture melt-blown nonwovens, feed polypropylene functional masterbatch directly into the screw extruder, melt and extrude at 270°C, and then pass through the melt filter and metering pump, and then input into the melt The spinneret hole of the spray die head is sprayed out, and under the action of hot air blowing at 270°C on both sides of the spinneret hole of the melt blown die head, the melt-blown nano-microfiber can be made. By adjusting the speed of the screw and the metering pump, the fiber Mesh weight up to 50g / m 2 , and consolidated into the melt-blown nonwoven fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Transverse breaking strength | aaaaa | aaaaa |

| Transverse breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com