Infrared thermal imaging remote monitoring device for transmission tower

A technology of infrared thermal imaging and transmission tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0197] The present invention will be further described below in conjunction with accompanying drawing:

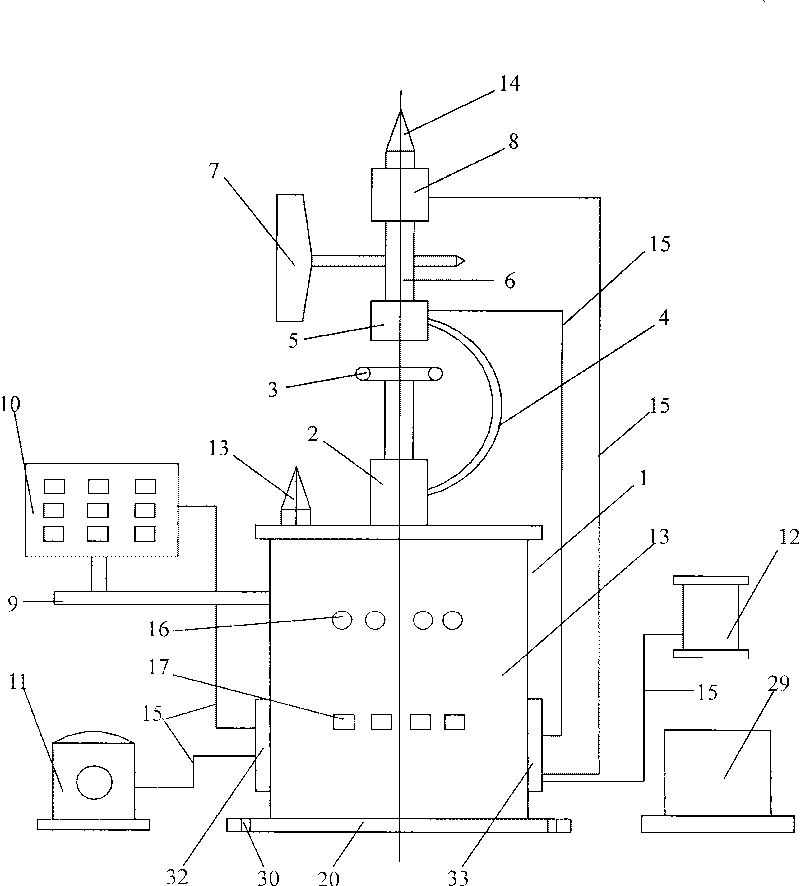

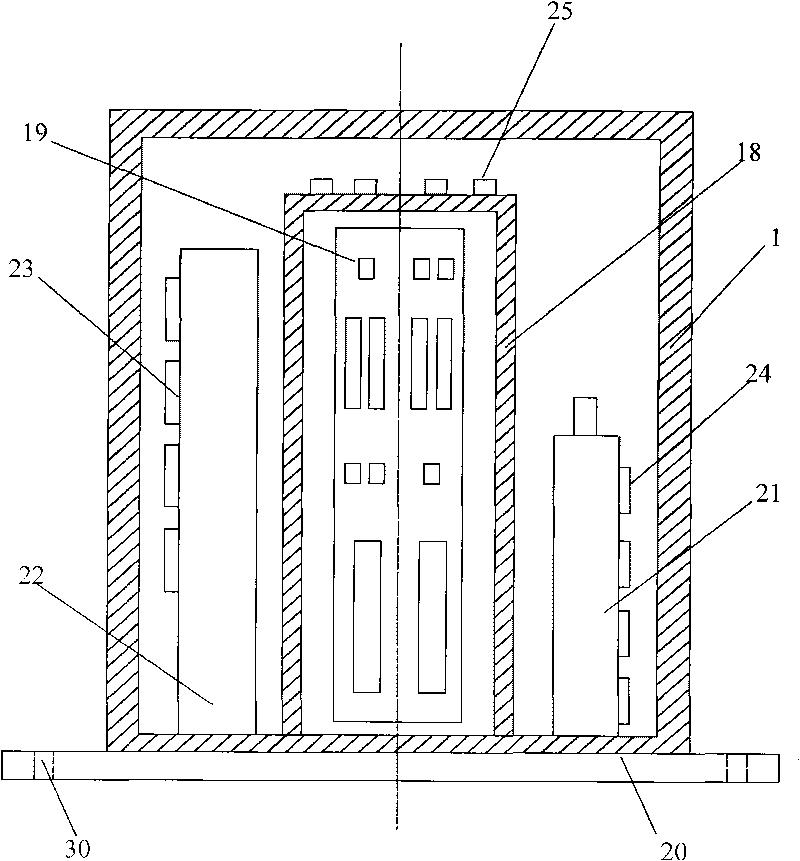

[0198] figure 1 Shown is the layout of the main chassis and its surroundings. The position and connection relationship of each part must be correct and the installation should be firm.

[0199] The main chassis is the main body of the device, made of stainless steel, good in strength, corrosion-resistant, and protective.

[0200] The wind speed scale, wind vane and sensor are set on the upper part of the main box to measure the wind direction and wind speed on the transmission tower and transmit them to the ground.

[0201] The solar panel transmits electric energy to the storage battery in the main chassis for storage of the circuit board operation and signal transmission.

[0202] Install an infrared thermal imager on the right side of the main box to monitor the temperature of the connecting board and the connecting terminal on the high-voltage transmission line tower,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com