Biological treatment device for exhaust gas

A technology of biological treatment and biological treatment pool, which is applied in the direction of air quality improvement, separation of dispersed particles, chemical instruments and methods, etc. It can solve problems such as difficulty in adapting to large-scale engineering applications, treatment effect not meeting requirements, troublesome collection and processing, etc. , to achieve the effect of good microbial film-hanging characteristics, convenient procurement and processing, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

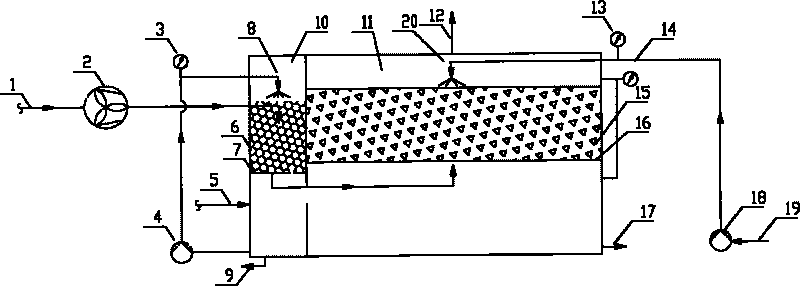

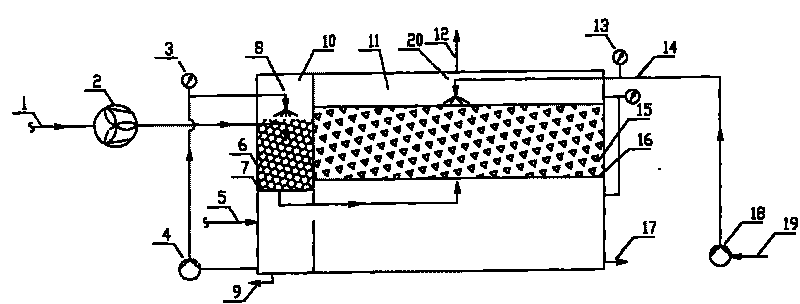

[0012] Such as figure 1 As shown, the exhaust gas is sent to the pre-wash tank 10 through the air inlet pipe 1 under the action of the air inlet fan 2, and the exhaust gas after passing through the spray packing layer 6 enters the biological treatment through the air outlet in the spray tank and the biological treatment tank. pool 11, and then discharge into the atmosphere by the exhaust pipe 12 at the upper end of the biological treatment pool after passing through the filler layer 15 of the biological treatment pool.

[0013] The spray water is continuously sprayed to the surface of the spray packing layer 6 through the spray nozzle 8 at high speed under the action of the spray water pump 4 (3-4 bar), forming a liquid film, and then enters the spray water pump 4 again through the spray water pipe. When the exhaust gas passes through the spray packing layer 6, it fully contacts with the liquid film formed on its surface, a part of the pollutants are absorbed into the spray wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com