Production method and production equipment for synthesizing ethanolamine by ethylene oxide

A technology of ethylene oxide and ethanolamine is applied in the preparation of organic compounds, the method of chemically changing substances by atmospheric pressure, chemical instruments and methods, etc. , the safety factor is improved, the effect of good condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

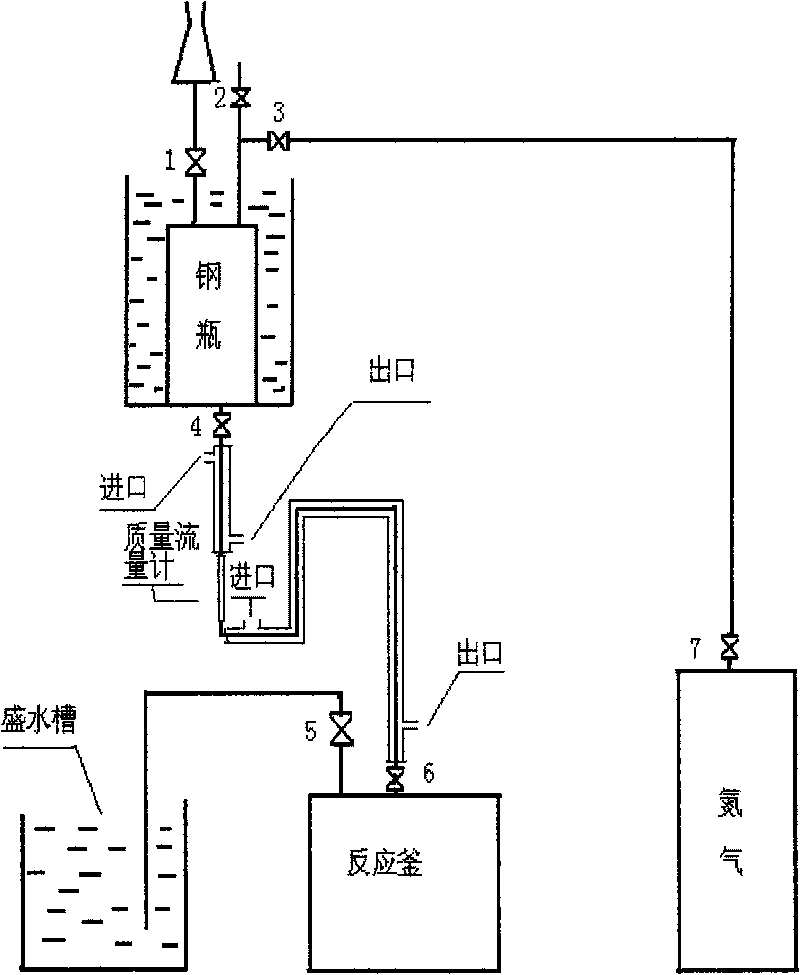

[0038] Example 1: Measure 60 ml of ethylene oxide with a mass content of ≥99% and 100 ml of ammonia water with a mass content of 25% and put them in a freezer at -10 to 5°C for later use. Attached figure 1After the equipment is installed, the pressurizing valves 3 and 7 and the tail gas absorption valve 5 are in the closed state, and the mass flow meter and other valves are in the open state. Pour the prepared ammonia water into the cylinder from the feeding funnel. Close the feed valves 1 and 2, open the pressurization valves 3 and 7, after the ammonia water enters the reactor completely, the internal pressure of the reactor starts to rise until the reading on the nitrogen meter above the reactor is 1.5Mpa, close the pressurization valves 3 and 7 And feed valve 4, open feed valve 1,2. Quickly pour the prepared ethylene oxide into the cylinder from the funnel, and close the feed valves 1 and 2.

[0039] Turn on the heat transfer device and stirring device of the reactor, an...

example 2

[0040] Example 2: Measure 80 ml of ethylene oxide with a mass content of ≥99% and 150 ml of ammonia water with a mass content of 25% and put them in a freezer at -10 to 5°C for later use. Attached figure 1 Install the equipment. The pressurizing valves 3 and 7 and the tail gas absorbing valve 5 are in the closed state, and the mass flow meter and other valves are in the open state. Pour the prepared ammonia water from the funnel into the cylinder. Close feed valve 1, 2, open pressurization valve 3, 7, after ammoniacal liquor enters reactor completely, reactor internal pressure begins to rise, until the reading on the nitrogen gauge above reactor is 1.8MPa, close pressurization valve 3, 7 and feed valve 4, open valves 1 and 2. Quickly pour the prepared ethylene oxide into the cylinder from the feeding funnel, and close the feeding valves 1 and 2.

[0041] Turn on the condensing device and stirring device of the reactor, and control the temperature of the reactor at 25-30°C....

example 3

[0042] Example 3: Measure 110 ml of ethylene oxide with a mass content of ≥99% and 200 ml of ammonia water with a mass content of 25% and put them in a freezer at -10 to 5°C for later use. Attached figure 1 Install the equipment. The pressurizing valves 3 and 7 and the tail gas absorbing valve 5 are in the closed state, and the mass flow meter and other valves are in the open state. Pour the prepared ammonia water into the cylinder from the feeding funnel. Close feed valve 1, 2, open pressurization valve 3, 7, after ammoniacal liquor enters reactor completely, reactor internal pressure begins to rise, until the reading on the nitrogen gauge above reactor is 1.8MPa, close pressurization valve 3, 7 and feed valve 4, open valves 1 and 2. Quickly pour the prepared ethylene oxide into the cylinder from the funnel, and close the feed valves 1 and 2.

[0043] Turn on the condensing device and stirring device of the reactor, and control the temperature of the reactor at 25-30°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com