Method for producing no-fishy smell scale collagen peptide by utilizing macroporous absorbent resin

A fish scale collagen and collagen peptide technology, which is applied in the field of fish scale collagen peptide production, can solve the problems of product odor, low overall quality, and low activity, and achieve the effect of ensuring activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

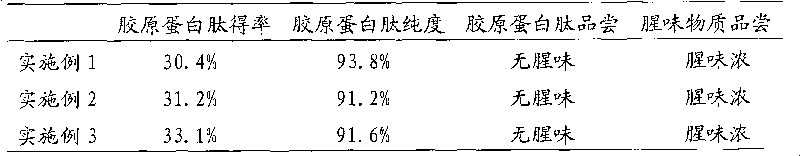

Embodiment 1

[0029] Soak 20kg of fish scales in 0.4mol / L HCl, which is 5 times the weight of the relative fish scales, for 20 hours, wash with water until neutral, then soak in 0.1 mol / L NaOH, which is 5 times the weight of the relative fish scales, for 20 hours, and wash in water until neutral; Double water, hydrolyze 200g of papain for 2.5 hours, hydrolysis pH 7.0, hydrolysis temperature 50°C; after enzymolysis, heat to 90°C, keep for 10 minutes to inactivate the enzyme; the enzymolysis solution is decolorized by activated carbon and then filtered; the obtained clarified enzymolysis solution On the macroporous adsorption resin column, the column loading conditions are pH5.6, the flow rate is 3BV / h, and the column volume is 5BV; after the column is loaded, it is eluted with 2BV20% ethanol at an elution rate of 1BV / h, and then washed with 3BV pure water to The eluent has no obvious ethanol smell, collect ethanol eluate and pure water eluate after alcohol, spray dry after dealcoholization, a...

Embodiment 2

[0031] Soak 20kg of fish scales in 0.4mol / L HCl, which is 5 times the weight of the relative fish scales, for 20 hours. Double water, hydrolyze 400g of animal proteolytic enzyme for 2.5h, hydrolysis pH 6.0, hydrolysis temperature 60°C; after enzymolysis is completed, heat to 90°C and keep for 10 minutes to kill the enzyme; the enzymolysis solution is decolorized by activated carbon and then filtered; The solution is put on a macroporous adsorption resin column, the column loading conditions are pH5.8, the flow rate is 4BV / h, and the column volume is 6BV; after the column is completed, it is eluted with 3BV30% ethanol, and the elution rate is 2BV / h, and then purified with 4BV Wash with water until the eluent has no obvious ethanol smell, collect the ethanol eluate and pure water eluate after alcohol, spray dry after dealcoholization, and obtain 5.1g of fishy smell substance; then elute with 3BVpH7.4 ammonia water, the elution speed is 2BV After washing with 4BV pure water until...

Embodiment 3

[0033] Soak 20kg of fish scales in 0.4mol / L HCl, which is 5 times the weight of the relative fish scales, for 20 hours, wash with water until neutral, then soak in 0.1 mol / L NaOH, which is 5 times the weight of the relative fish scales, for 20 hours, and wash in water until neutral; Double the water, hydrolyze with 600g alkaline protease for 2.5h, the hydrolysis pH is 7.5, and the hydrolysis temperature is 55°C. After the enzymolysis is completed, heat to 90°C and keep for 10 minutes to inactivate the enzyme; the enzymolysis solution is decolorized by activated carbon and then filtered; the obtained clarified enzymolysis solution is put on a macroporous adsorption resin column, and the column conditions are pH 6.0, flow rate 5BV / h, and The column volume is 7BV; after loading the column, use 4BV40% ethanol to elute, the elution speed is 3BV / h, and then wash with 5BV pure water until the eluate has no ethanol smell, collect ethanol eluate and pure water eluate after alcohol, Spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com