System device with co-action of ultrasonic wave and far infrared ray on engine

A technology of far-infrared rays and system devices, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems that the products have not been widely used, and achieve the effects of stable and long-lasting emission efficiency, improved power, fuel saving and emission reduction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

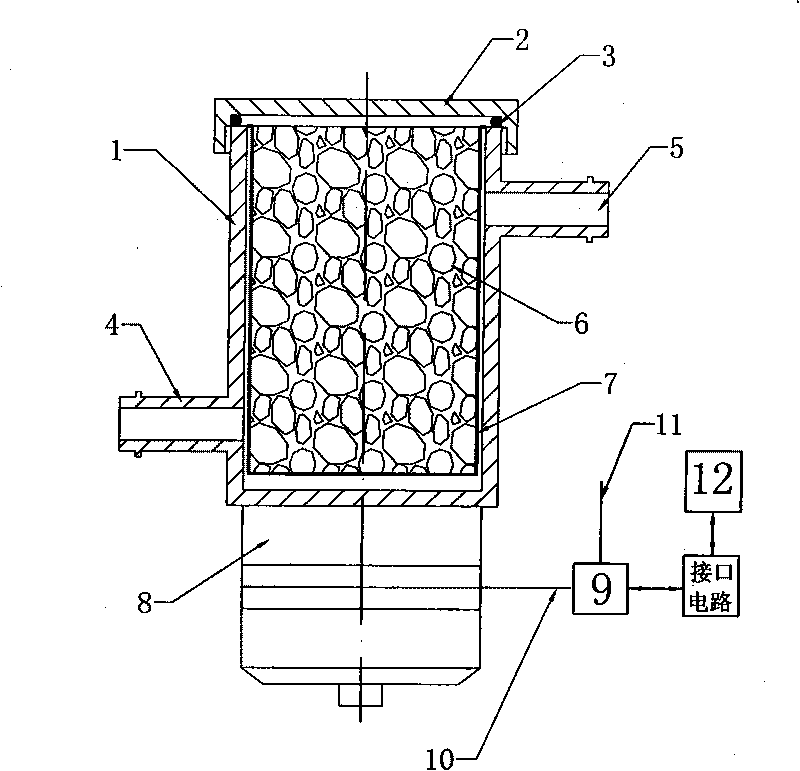

[0052] This example figure 1 Shown: figure 1 Described is the combined part of the fuel action unit, the ultrasonic generator and the single-chip microcomputer in the system device of the present invention. It is also the core part of the present invention. It includes housing 1, cover 2, sealing ring 3, oil inlet 4, oil outlet 5, far-infrared ceramics 6, filter element assembly 7, ultrasonic transducer 8 (the above constitutes a fuel action unit), ultrasonic Generator 9, signal line 10, power line 11, single-chip microcomputer 12.

[0053] The far-infrared ceramics 6 can be loaded into the housing 1 by opening the cover 2. In this embodiment, the far-infrared ceramics 6 are spherical in shape. The cover 2 and the housing 1 are screwed and fixed and sealed with a sealing ring 3 to prevent fuel oil and far-infrared ceramics 6 from leaking out. The filter element assembly 7 inside the housing 1 is used to prevent the far-infrared ray ceramics 6 from leaking out of the housin...

Embodiment 2

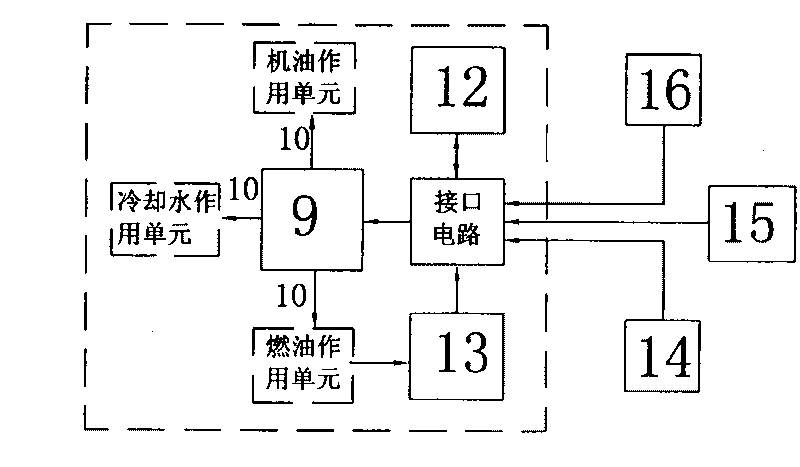

[0058] Such as figure 2 As shown, it is a schematic block diagram of the electronic control system containing the fuel oil action unit, the cooling water action unit, and the lubricating oil action unit with the single-chip microcomputer of the present invention.

[0059] Including fuel action unit, cooling water action unit, engine oil action unit, ultrasonic generator 9, single chip microcomputer 12, fuel temperature sensor 13, water temperature sensor 14, intake air temperature sensor 15, throttle opening sensor and / or speed sensor 16. The single-chip microcomputer 12 is respectively connected with the fuel temperature sensor 13, the water temperature sensor 14, the intake air temperature sensor 15, the throttle opening sensor and / or the speed sensor 16 and the ultrasonic generator 9 through an interface circuit. The fuel oil action unit of the above three action units is the fuel oil action unit described in Embodiment 1. On this basis, this embodiment further expands the...

Embodiment 3

[0073] In Embodiment 2, the fuel action unit and the engine oil action unit described in the present invention can also be extended in their functional application, that is, they can be used as a fuel filter and an oil filter respectively.

[0074] The following is only an example of extending the oil action unit to an oil filter:

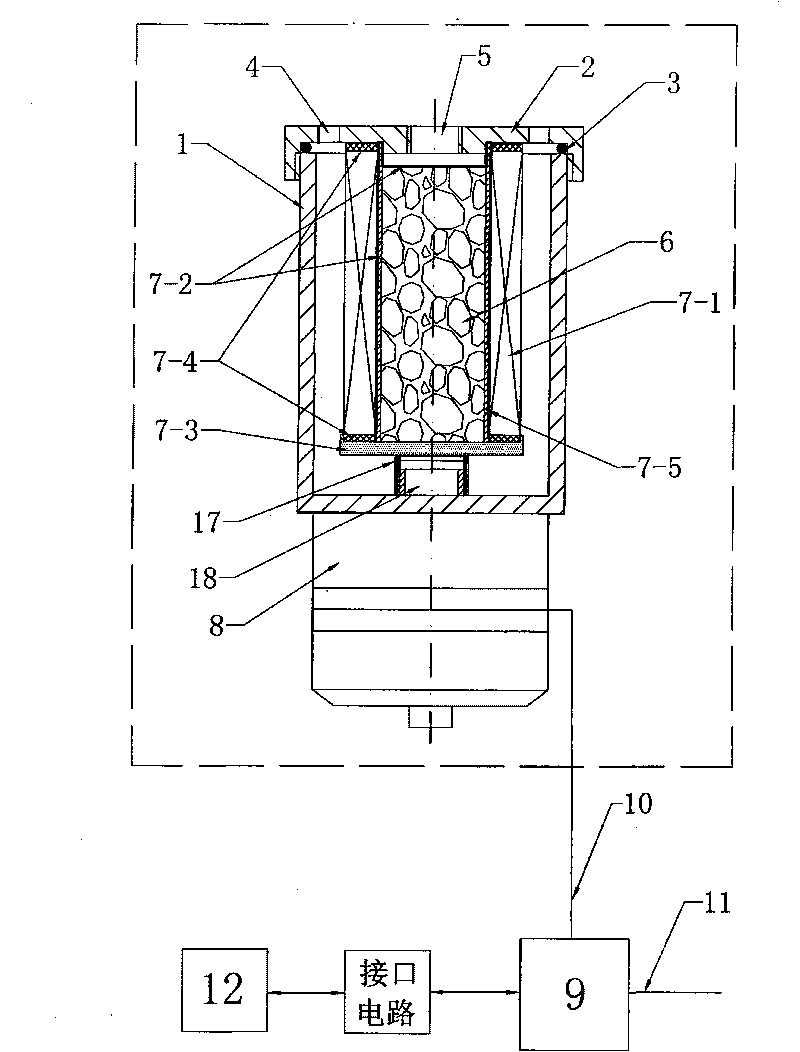

[0075] Such as image 3 Shown in the dotted line box is a view of the main structure of the oil action unit of this embodiment. Its structure is composed of shell 1, cover 2, sealing ring 3, oil inlet 4, oil outlet 5, far-infrared ceramics 6, paper filter element 7-1, metal filter 7-2, pressure plate 7-3, Gasket 7-4, support tube 7-5, ultrasonic transducer 8, elastic support 17, support seat 18.

[0076] The filter element assembly 7 described in the present invention is composed of a paper filter element 7-1 on the outer layer, an inner layer and an upper metal filter screen 7-2, a pressing plate 7-3, a gasket 7-4 and a support Tubes 7-5 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com