Electromagnetic wave absorption product and manufacturing method thereof

A technology for absorbing products and manufacturing methods, which is applied in the direction of shielding, instruments, and parts of instruments, etc., and can solve problems such as endangering the health of operators, unsatisfactory dispersion effect of fiber absorbing agents, and poor absorbing performance of electromagnetic wave absorbing products. , to achieve the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of Fe by water atomization 74 Cr 2 Mo 2 Sn 2 P 10 Si 6 B 2 C 2 Soft magnetic powder, its microscopic appearance is like Picture 9 As shown, the particles in the powder are approximately spherical. Using absolute ethanol as the dispersion medium, ball milled in a planetary ball mill at 400 rpm for 16 hours, the microscopic appearance is as Picture 10 As shown, the nearly spherical powder turns into a flat powder. The average thickness of the obtained flat powder is about 0.8-1μm, and the aspect ratio is about 10-80 (the powder may contain a small amount of irregular small particles, because the content is very small, so it will not significantly affect the product's absorbing performance) . Subsequently, the powder was heat-treated in a vacuum heat treatment, and the process parameters were heat preservation at 440°C for 1 hour. The powder is insulated and coated with epoxy resin and low molecular polyimide. The specific operation method is as follows: diss...

Embodiment 2

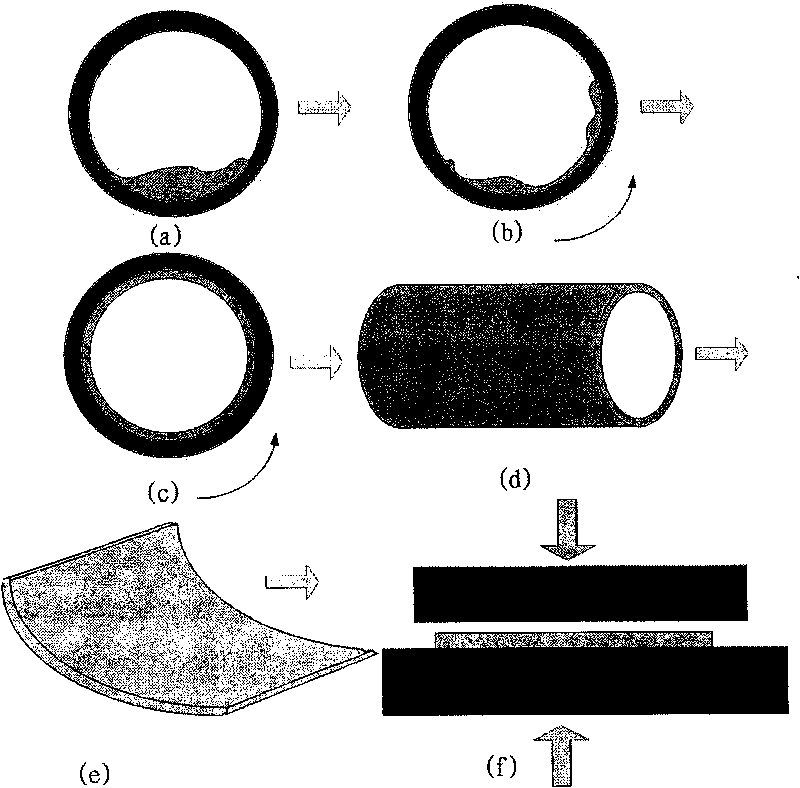

[0061] Using the same method as in Example 1, a flat powder wave absorbing agent was prepared. Mix it with a two-component liquid silicone resin at a filling rate of 20vol.%, according to Figure 8 The manufacturing process prepares three-dimensional electromagnetic wave absorbing products. The process uses dual-axis rotation, and the speed of both shafts is 100 rpm. Cured for 6h at room temperature. Demoulding to obtain three-dimensional electromagnetic wave absorbing products.

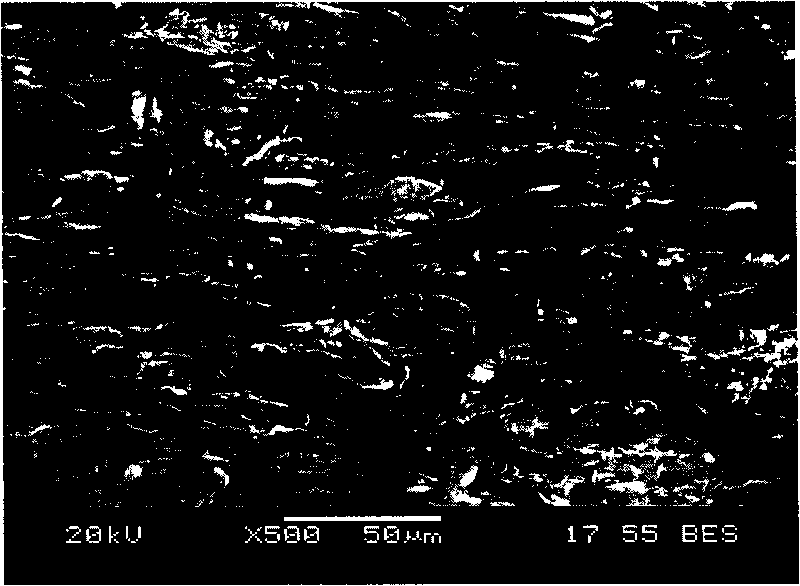

[0062] Observe its cross section with a scanning electron microscope, such as image 3 As shown, the absorber is distributed in orientation.

Embodiment 3

[0064] In order to obtain an electromagnetic wave absorbing sheet with a filling rate of 50 vol.%, the following experiment was performed.

[0065] Considering that the small amorphous particles in the absorber will reduce the filling rate of the electromagnetic wave absorbing sheet, FeNi with good plasticity is used 50 Aerosolized powder (shape like Picture 12 Shown) ball milling. Process: Using absolute ethanol as the dispersion medium, ball milled in a planetary ball mill at a speed of 400 rpm for 12 hours, the microscopic appearance is as Figure 13 As shown, the nearly spherical powder turns into a flat powder with a thickness of about 0.6-0.8 μm and an aspect ratio of about 50-200. Adopting pouring polyurethane with good fluidity as the polymer matrix, mixing it with flat powder wave absorbing agent, and putting it into a rotating mold for molding. The centrifugal force is 50G. After rotating for 30 minutes, heat the mold to 80° and keep it for 2 hours to make the polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Centrifugal force | aaaaa | aaaaa |

| Centrifugal force | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com