Green carbon dioxide supercritical fluid semiconductor cleaning equipment

A supercritical fluid, carbon dioxide technology, applied in semiconductor/solid-state device manufacturing, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cleaning a lot of water, pollute the environment, particle adsorption, etc. Enhance safety and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

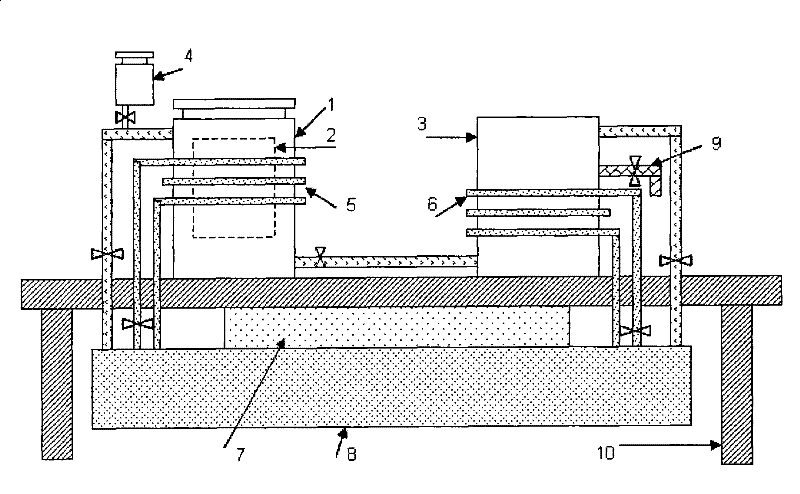

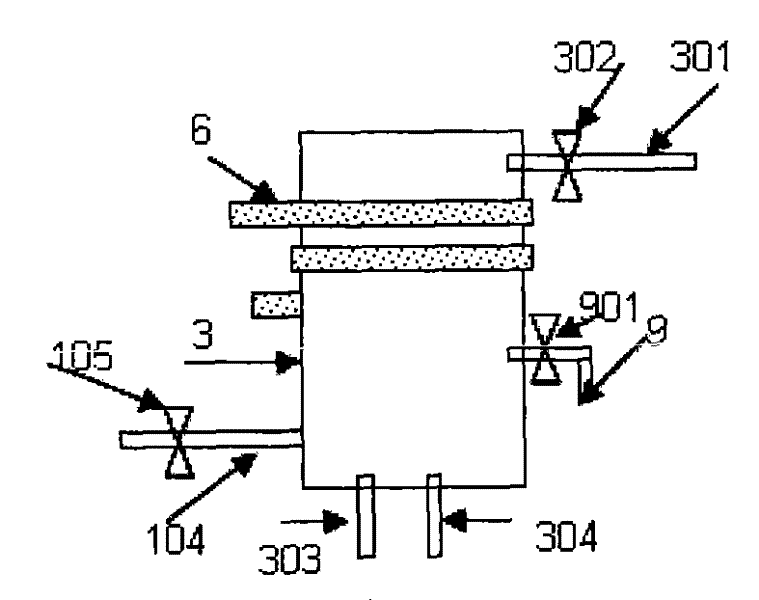

[0035] Such as figure 1 as shown, figure 1 Schematic diagram of the structure of the carbon dioxide superfluid semiconductor cleaning equipment provided by the present invention. The equipment is mainly composed of a working chamber 1, a separation chamber 3, a cleaning agent and co-solvent temporary storage tank 4, a temperature and pressure control system 7 and a carbon dioxide cycle control system 8. Wherein, both the main working chamber 1 and the separation chamber 3 are fixed on the support 10 .

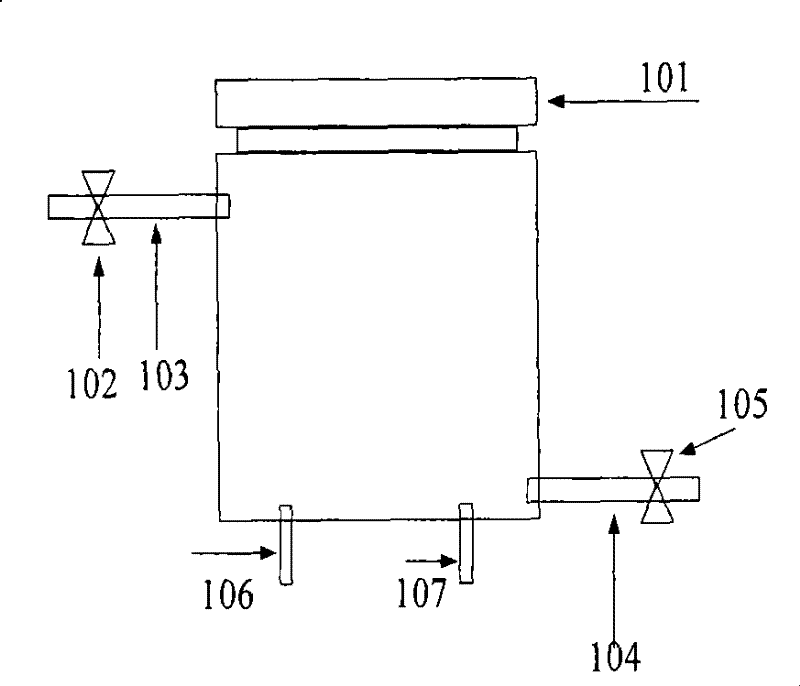

[0036] The main working chamber 1 is connected to the carbon dioxide storage tank through the main chamber liquid inlet pipe 103 with the liquid inlet solenoid valve 102, and is connected with the separation chamber 3 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com