Cadmium telluride in-situ passivation method of mercury cadmium telluride infrared focal plane chip

An infrared focal plane, mercury cadmium telluride technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problem of affecting the process stability of the device, loss of part passivation of the mercury cadmium telluride infrared focal plane detection chip performance, mercury cadmium telluride detection chip surface contamination and other issues, to achieve the effect of good passivation effect, high stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

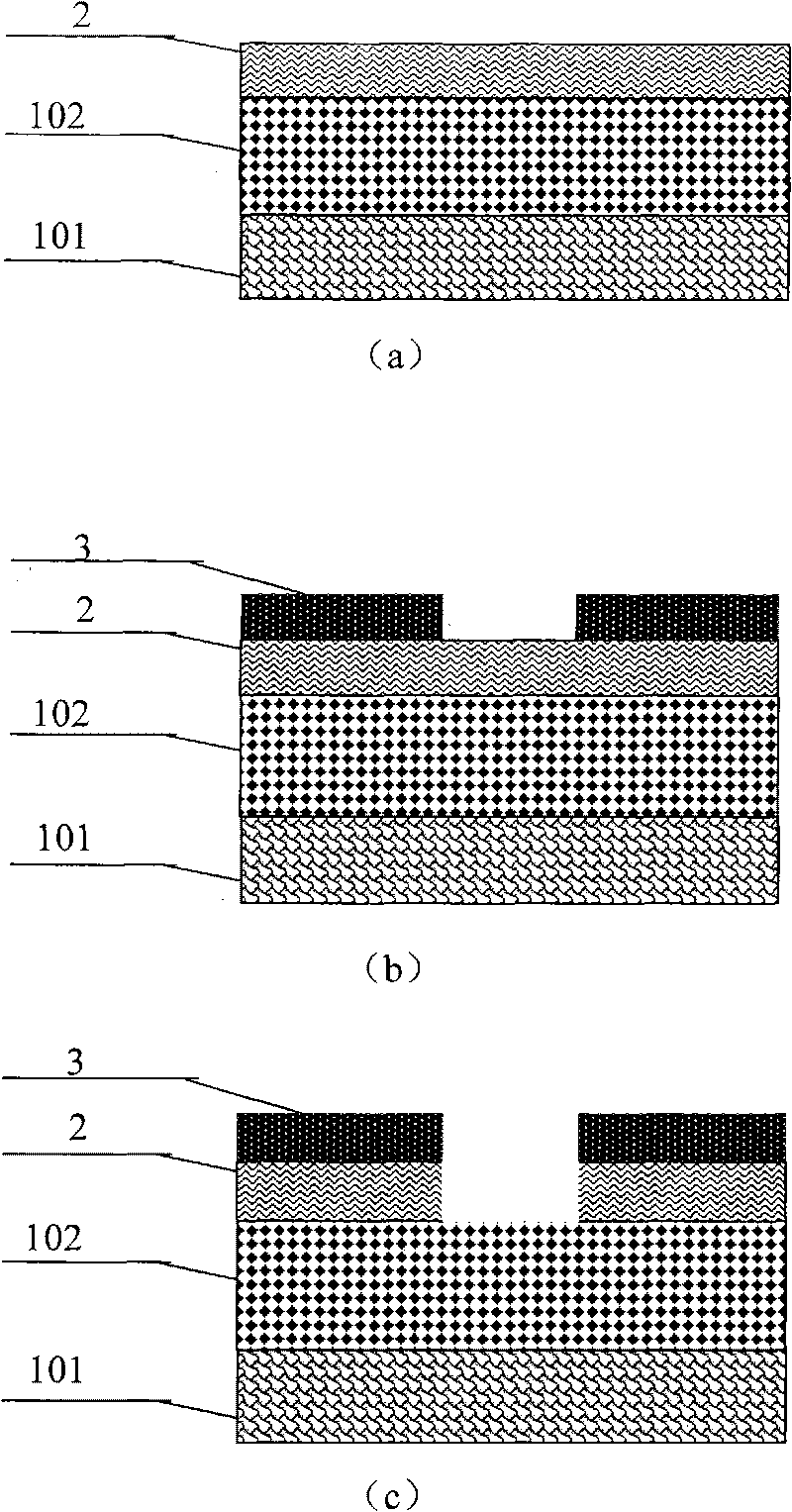

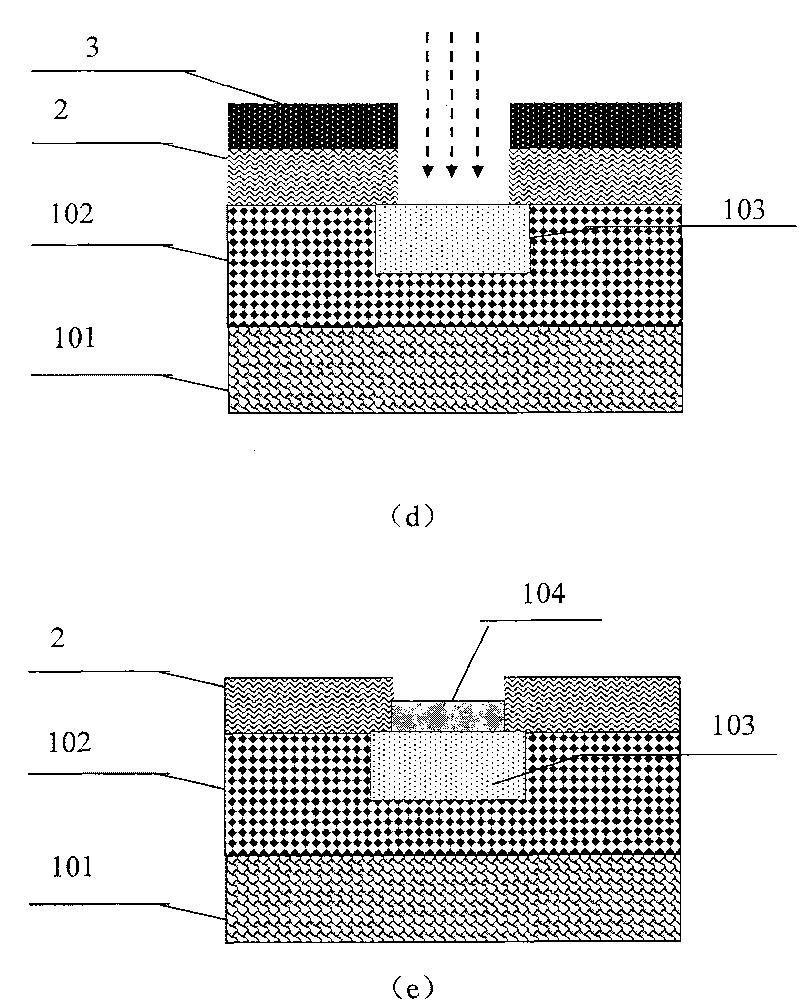

[0019] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

[0020] A. Using molecular beam epitaxy, at the end of the growth of the mercury cadmium telluride infrared detection material 1, a layer of cadmium telluride film 2 is grown in situ on the surface of the mercury cadmium telluride film 102, and the film thickness is

[0021] B. Using traditional photolithography technology, on the surface of the HgCdTe infrared focal plane detection chip, a photoresist masking film pattern 3 for limiting the ion implantation area is made. The thickness of the masking film is 1-3 μm, and the ion implantation area defined by the masking film pattern is Square array, the square side length is 20μm.

[0022] C. Utilize the wet chemical etching method to etch away the cadmium telluride thin film in situ in the ion implantation area limited by the pattern of the photoresist masking film. The etching solution used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com