WEB-based aluminum cold-rolling mill shape control man-machine interface operation method

A human-machine interface and shape control technology, applied in contour control, comprehensive factory control, comprehensive factory control, etc., can solve the problem that enterprise managers and technicians cannot keep abreast of equipment operation and personnel operations at any time, and remote fault diagnosis is difficult. The problem of high configuration cost can improve the degree of enterprise automation and informatization, facilitate remote fault diagnosis, and reduce system configuration costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

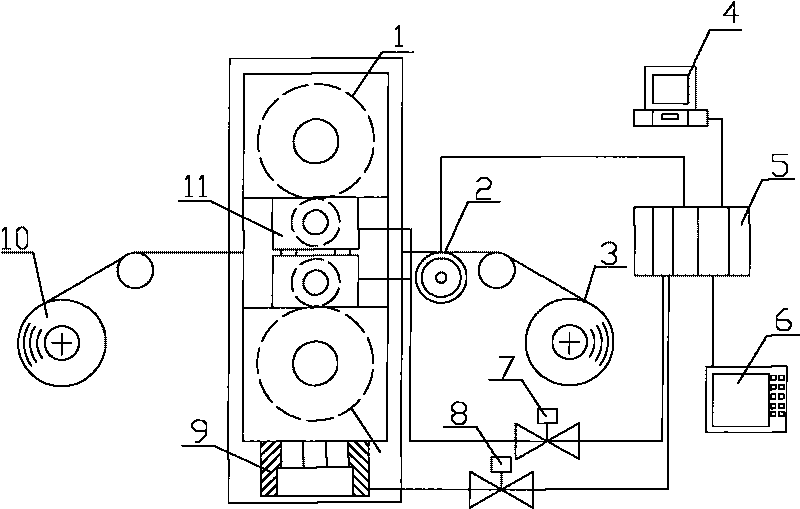

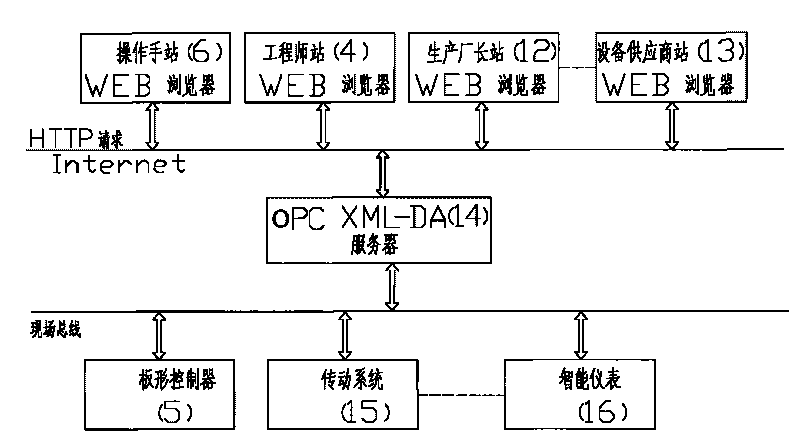

[0023] Aluminum cold rolling mill such as figure 1 As shown, it includes cold rolling mill 1, shape meter 2, coiler 3, engineer station 4, shape controller 5, operator station 6, bending roll servo valve 7, hydraulic cylinder servo valve 8, hydraulic pressure cylinder 9. Uncoiler 10, bending cylinder 11. The present invention is based on the WEB cold rolling mill strip shape control HMI system and network connection method, the system frame model is as follows figure 2 As shown, it includes a shape controller 5, an engineer station 4, a factory manager station 12, an equipment supplier station 13, an OPC XML-DA server station 14, a transmission system 15 and an intelligent terminal 16. The shape controller 5 adopts a programmable The controller PLC or the industrial control computer IPC, the OPC XML-DA server station 14 and the panel shape controller 5 are connected by Internet.

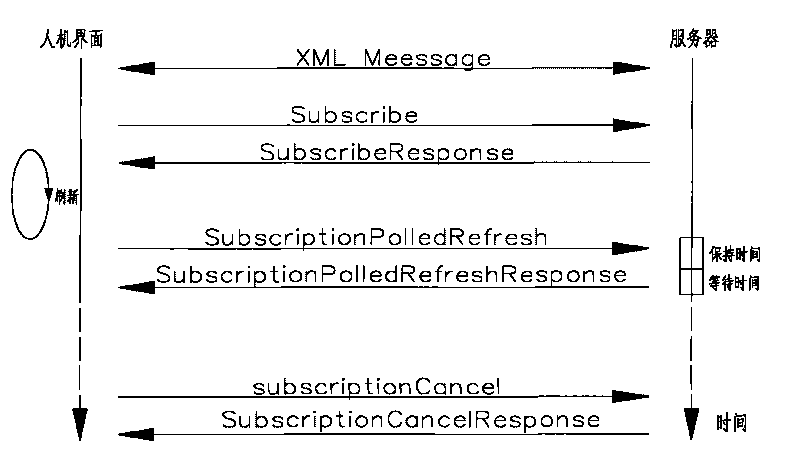

[0024] The man-machine interface workstation uses a PC equipped with IE browser instead of a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com