Welding method for welding vent pipe on oil filling pipe

A welding method and ventilation pipe technology, applied in welding equipment, high-frequency current welding equipment, metal processing equipment, etc., can solve the problems of high labor cost of materials, uneven brazing thickness, uneven welding surface, etc., and achieve material and Low labor cost, good welding stability and smooth welding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

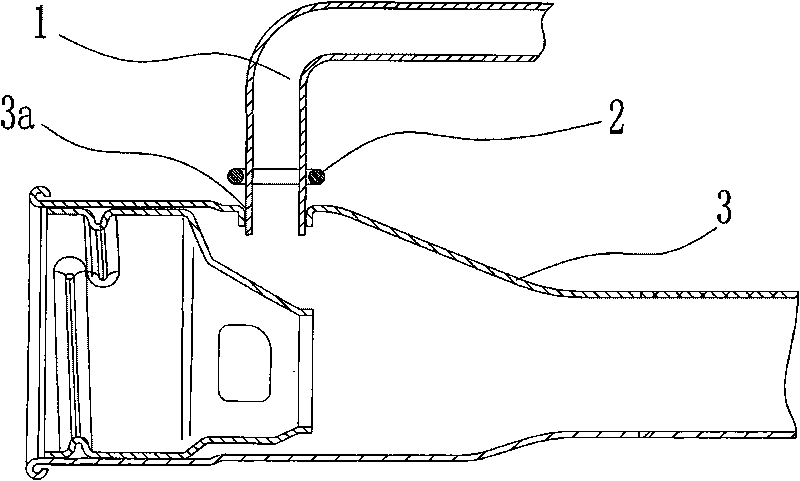

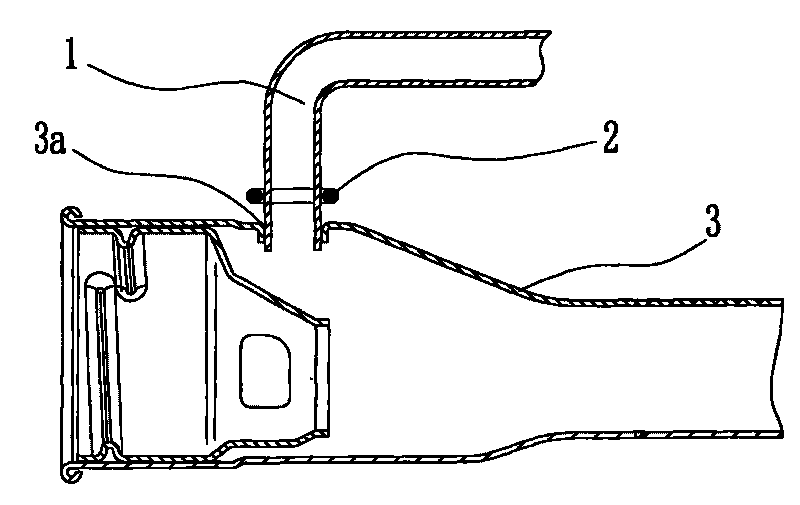

[0034] As shown in the figure, a welding method for welding a vent pipe on a fuel filler pipe includes the following steps:

[0035] a. Select the metal welding ring 2 that is compatible with the vent pipe 1 and set it on the periphery of the welding place of the vent pipe 1;

[0036] b. Select a high-frequency welding machine, and put the refueling pipe 3 on the bench fixture of the high-frequency welding machine, which is used to connect the connecting hole 3a of the refueling pipe 3, and the connecting hole 3a is placed upward;

[0037] c. Put the vent pipe 1 equipped with the metal welding ring 2 into the connecting hole 3a of the fueling pipe 3, and the connecting part of the venting pipe 1 and the fueling pipe 3 is perpendicular to the connecting hole 3a;

[0038] d. Fix the vent pipe 1, and make the metal welding ring 2 cover the top of the connecting hole 3a;

[0039] e. The high-frequency welding head of the high-frequency welding machine is surrounded by the periphe...

Embodiment 2

[0045] The weight percentage of silver in the above-mentioned metal welding ring 2 is 20%, and the weight percentage of copper is 80%. The remaining parts are the same as those in Embodiment 1, and will not be repeated here. However, it is worth noting that due to the change of the ratio of silver to copper, the melting point of the metal welding ring 2 has changed. Therefore, when setting the parameters, it should be adjusted according to the size of the welding seam.

Embodiment 3

[0047] The weight percentage of silver in the above-mentioned metal welding ring 2 is 30%, and the weight percentage of copper is 70%. The remaining parts are the same as those in Embodiment 1, and will not be repeated here. However, it is worth noting that due to the change of the ratio of silver to copper, the melting point of the metal welding ring 2 has changed. Therefore, when setting the parameters, it should be adjusted according to the size of the welding seam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com