Nanometer reinforced bismuth base lead-free high-temperature solder and preparation method thereof

A nano-enhanced, high-temperature welding technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problem of difficulty in controlling the uniformity of nano-enhanced particles, limited use of size restrictions, poor brightness of solder joints, etc. problems, to achieve the effect of improving electrical conductivity, good sealing, and bright solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

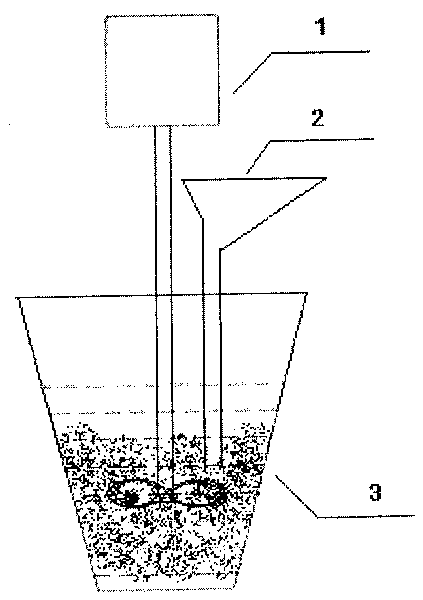

[0038] figure 1 It is a schematic diagram of the preparation device of the nano-reinforced bismuth-based lead-free high-temperature solder of the present invention. Among them, 1 is a stirrer; 2 is a feeding port for bismuth-based powder, ammonia water (or other weak base), reducing agent, etc.; 3 is a turbid liquid container.

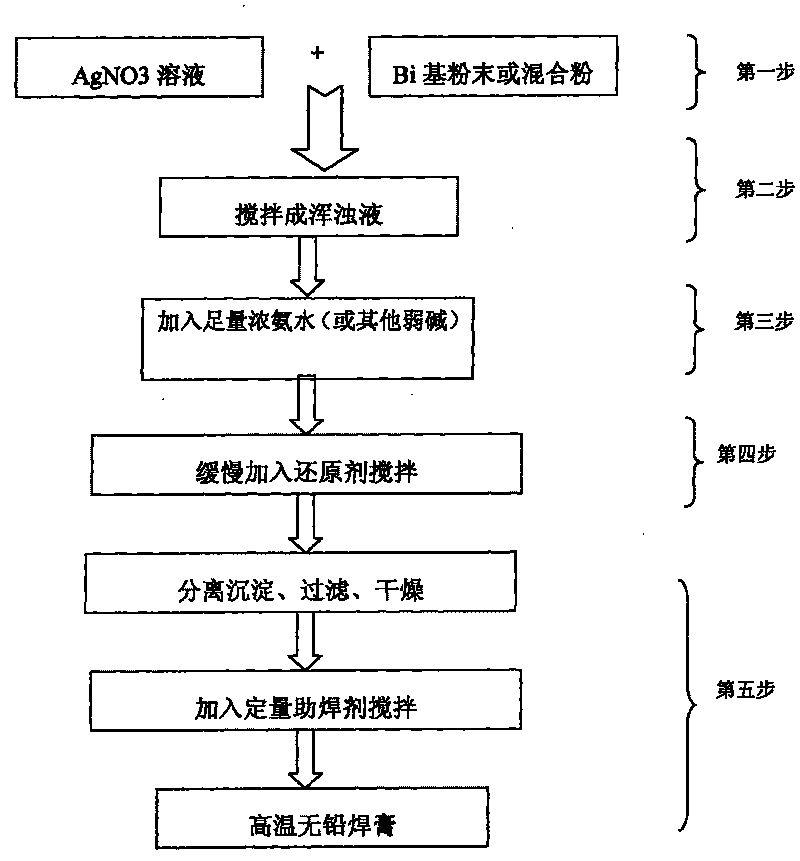

[0039] like figure 2 Shown is a flow chart of the preparation process for preparing the nano-reinforced bismuth-based lead-free high-temperature solder of the present invention. The first step: take bismuth powder (or prepare bismuth / antimony powder in proportion), and its preparation method can be any known powder-making technology such as mechanical crushing or medium atomization; Second step: quantitative bismuth powder (or bismuth powder / antimony powder) evenly import a quantitative silver nitrate solution with a certain concentration of stirring device, and constantly stir to make the solution become a uniform turbid liquid; the third step: ta...

Embodiment 2

[0047] Embodiment 2 (Bi-10Sb)+2.5%Ag nano-reinforced bismuth-based lead-free high-temperature solder and its preparation:

[0048] Prepare 20kg of Bi-10Sb alloy solder, atomize the molten Bi-10Sb alloy solder by ultrasonic atomization powder making technology, and sieve and classify, take 975g of 3# powder (25-45um);

[0049] Weigh 25g of silver scraps, pour into nitric acid and stir thoroughly to dissolve Ag completely;

[0050] Pour the weighed Bi-10Sb alloy powder into the prepared AgNO 3 Solution, stir to make the solution a uniform turbid liquid, in order to prevent the precipitation of Bi-10Sb alloy powder;

[0051] Gradually add sufficient amount of ammonia water (1mol solute) to the turbid liquid under stirring, so that the silver nitrate can completely form a complex (complex (Ag(NH3) n + ) solution);

[0052] Slowly drop excess formaldehyde into the turbid liquid and continue stirring to reduce the complex to form a uniform composite powder of nano-Ag powder and ...

Embodiment 3

[0055] Embodiment 3 (Bi-10Sb-0.5Sn)+5%Ag nano-reinforced bismuth-based lead-free high-temperature solder and its preparation:

[0056] Prepare 50kg of Bi-10Sb-0.5Sn alloy solder, atomize the molten Bi-10Sb-0.5Sn alloy solder by centrifugal atomization powder making technology, and sieve and classify, take 950g of 3# powder (25-45um);

[0057] Pour the weighed Bi-10Sb-0.5Sn powder into 0.463mol (78.7g solute) of AgNO 3 Solution, stirring, so that the solution becomes a uniform turbid liquid, in order to prevent the precipitation of Bi-10Sb-0.5Sn alloy powder;

[0058] Gradually add a mixed solution of dilute NaOH and ammonia water to the turbid liquid under stirring, so that silver nitrate can completely form a complex (complex (Ag(NH3) n + ) solution);

[0059] Slowly add excess glucose solution to the turbid solution under stirring conditions, and reduce the complex to form a uniform composite powder of nano-Ag powder and Bi-10Sb-0.5Sn alloy powder;

[0060] Pour the solu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap