Treatment method for organic industrial wastewater

A technology for industrial wastewater and treatment methods, which is applied in biological water/sewage treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc., and can solve high equipment investment and operation costs, waste of water resources, and increased wastewater discharge Total volume and other issues to achieve the effect of low operating cost, environmental protection and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

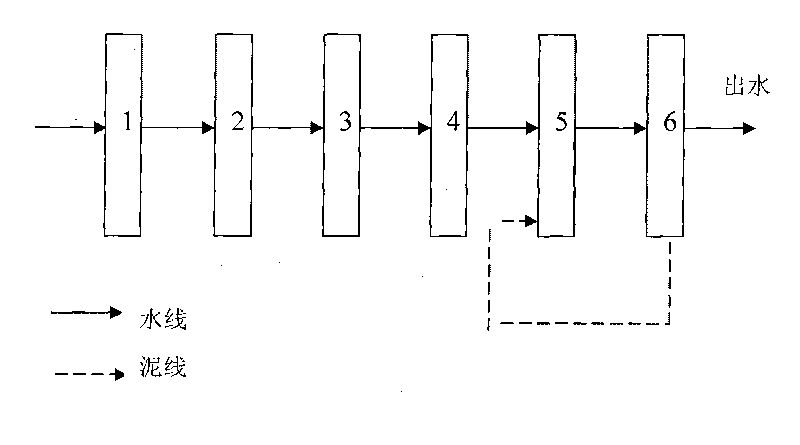

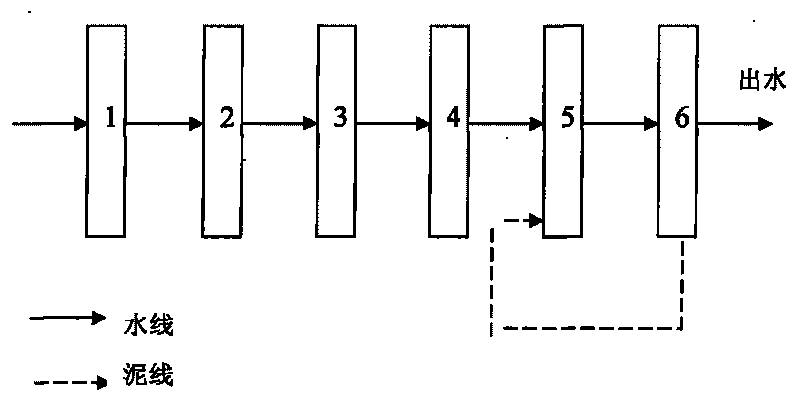

Embodiment 1

[0040] The phenolic wastewater (COD 3688mg / L) from a chemical plant was used for testing. The wastewater is adjusted to pH 4.0 in the adjustment tank 1, and then enters the iron-carbon reaction tank 2, the amount of iron filings is 150g / L, and the activated carbon particles are added according to the iron-carbon ratio (W / W) of 1:1, and the reaction time is 90min. Then enter the Fenton reaction cell 3, H 2 o 2 The dosage is 40mmol / L, the reaction time is 120min, then the wastewater enters the neutralization sedimentation tank 4, the pH is adjusted to 9.0, and after standing for 6 hours, it enters the aerobic aerobic granular sludge tank 5, where it is aerated for 8 hours and then drained for 4 hours It is a cycle, the residence time is 12h, and the secondary sedimentation tank 6, the residence time is 3h, and the water is discharged. Ca 2+ The addition amount is 40mg / L, the ultrasonic frequency is 21kHz, the power is 20W, and the irradiation time is 10min to cultivate and do...

Embodiment 2

[0043] Anthraquinone dyeing and finishing wastewater (COD829mg / L) was taken from a factory for testing. Adjust the wastewater pH to 3.0 in the adjustment tank 1, and then enter the iron-carbon reaction tank 2, the amount of iron filings is 200g / L, and the activated carbon particles are added according to the iron-carbon ratio (W / W) of 3:1, and the reaction time is 150min. Then enter the Fenton reaction cell 3, H 2 o 2 The dosage is 60mmol / L, the reaction time is 90min, then the wastewater enters the neutralization sedimentation tank 4, the pH is adjusted to 9.0, and after standing for 6 hours, it enters the aerobic aerobic granular sludge tank 5, where it is aerated for 6 hours and then drained for 2 hours It is a cycle, the residence time is 8h, and the secondary sedimentation tank 6, the residence time is 3h, and the water is discharged. Ca 2+ The addition amount is 20mg / L, the ultrasonic frequency is 25kHz, the power is 30W, and the irradiation time is 15min to cultivate...

Embodiment 3

[0046] Take a factory yeast wastewater (COD 6078mg / L) for experiment. Adjust the wastewater pH to 2.0 in the adjustment tank 1, and then enter the iron-carbon reaction tank 2, the amount of iron filings is 50g / L, and the activated carbon particles are added according to the iron-carbon ratio (W / W) of 0.5:1, and the reaction time is 30min. Then the wastewater enters the Fenton reaction tank 3, H 2 o 2 The dosage is 50mmol / L, and the reaction time is 60min. Then the waste water enters the neutralization sedimentation tank 4, the pH is adjusted to 10.0, and enters the aerated aerobic granular sludge tank 5 after standing for sedimentation for 1 hour, with aeration for 5 hours, and standing for drainage for 3 hours as a cycle, the residence time is 8 hours, and passed through Secondary settling tank 6, the residence time is 3h, and the water is discharged. Ca 2+ The addition amount is 10mg / L, the ultrasonic frequency is 28kHz, the power is 20W, and the irradiation time is 2min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com