Method for preparing iso-octyl palmitate

A technology for isooctyl palmitate and palmitic acid, applied in the field of preparing isooctyl palmitate, can solve the problems of complex post-processing procedures, strong oxidizing property of concentrated sulfuric acid, strong acidity of concentrated sulfuric acid, etc., and achieves environmental friendliness and equipment investment. And the effect of low operating cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

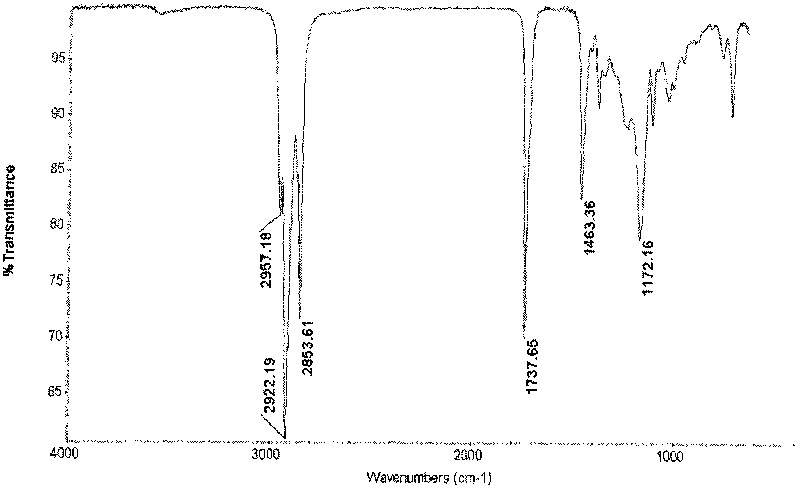

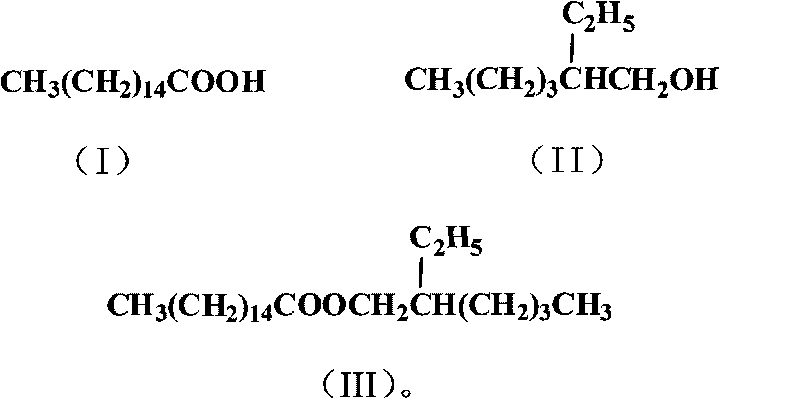

Image

Examples

Embodiment 1

[0027] (1) Esterification reaction: In a 100mL four-neck flask equipped with a stirrer, reflux condenser, and dropping funnel, add 0.078mol of palmitic acid and 5mL of isooctyl alcohol, and add 3 / 4 cyclohexane, nitrogen protection. Heat with an oil bath. After the palmitic acid is completely melted, add 0.525g of stannous oxalate solid acid catalyst and 5mL of cyclohexane, heat and reflux under normal pressure and stir. When the water produced by the reaction is separated from the water separator, start Timing, the reaction temperature is 150°C, and then 13.5mL of isooctyl alcohol is evenly and slowly added dropwise to the reactor through the dropping funnel, and the reaction stops when it enters the water separator until there is no water. The reaction time is 3.5 hours, and the isooctyl palmitate is obtained. The ester crude product is 30.5g, and the acid value is determined by sampling. The determination of the acid value adopts KOH solution as a standard solution and pheno...

Embodiment 2-5

[0030] Except following difference, all the other operations are identical with embodiment 1, and the addition of palmitic acid is identical with that in embodiment 1, and the amount of substance of palmitic acid and isooctyl alcohol is as shown in table 1:

[0031] Table 1

[0032] Example

Embodiment 6-9

[0034] Difference with embodiment 1 is that change catalyst consumption, preparation process is identical with the method for embodiment 1, and the percentage of catalyst consumption and palmitic acid and isooctyl alcohol feeding quality is as shown in table 2:

[0035] Table 2

[0036] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com