Method for extracting ascorbyl-2-phosphate through bipolar membrane electrodialysis

A technology of bipolar membrane electrodialysis and ascorbic acid phosphate, which is applied in electrodialysis, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of low product yield, large waste water output, Insufficient dechlorination and other problems can be achieved to improve the separation yield, reduce the cost of raw materials, and reduce the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

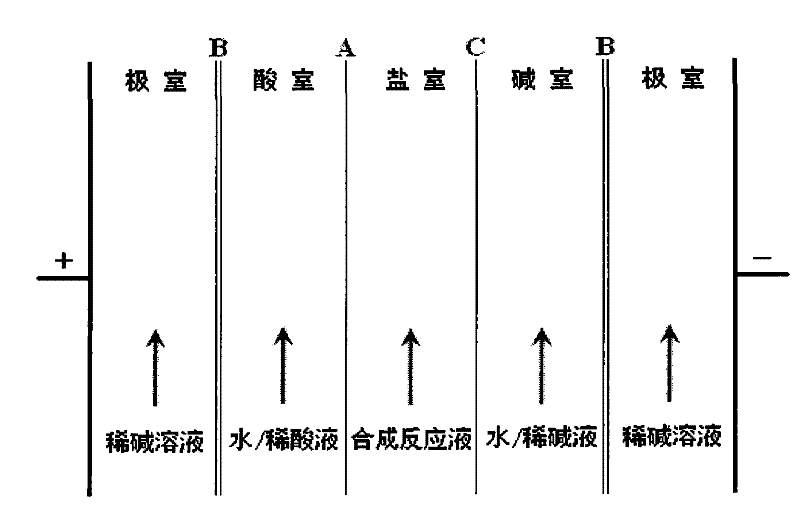

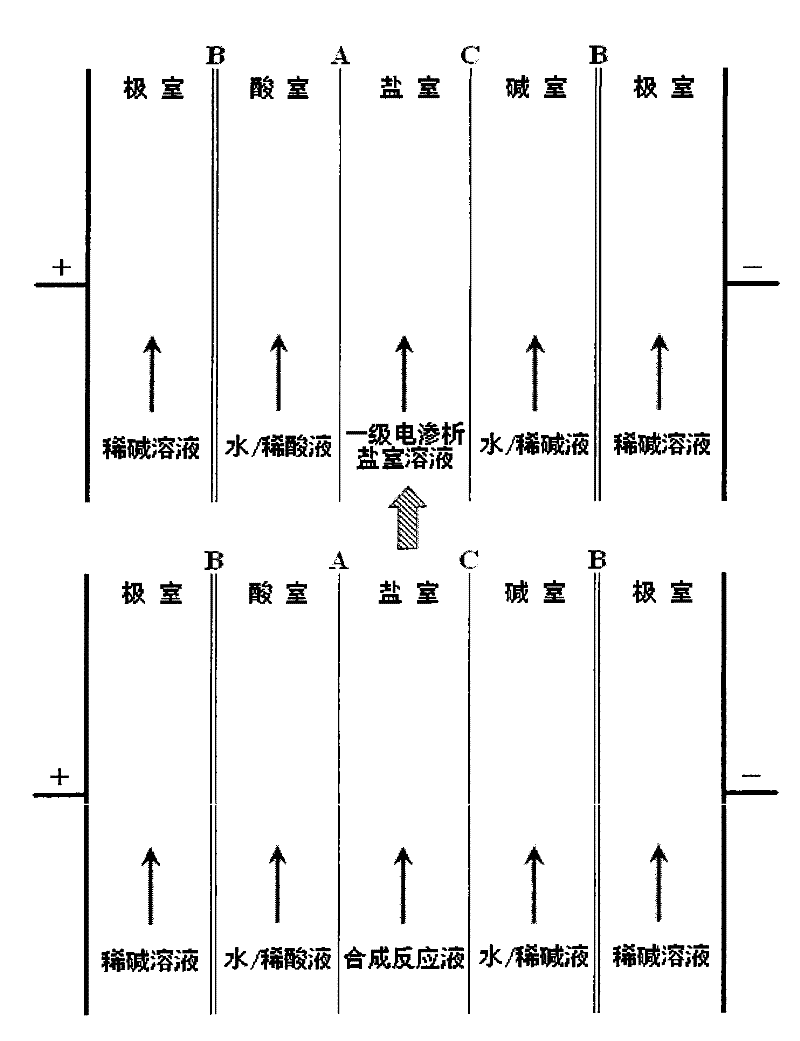

[0045] Pass the synthesized mixed solution into acid / salt / alkali three-chamber electrodialyzer (attached figure 1 ) of the salt chamber, and circulate at a speed of 50L / h. Then pass 500ml of deionized water into the two chambers of acid and alkali respectively, and circulate at a speed of 50L / h respectively. Use 5 mol / L KOH solution to stably control the pH of the salt chamber to 9 through a potentiometric titrator. The control voltage is 10V, and the maximum current density is 10mA / cm 2 , the operating temperature is 30 ° C, after 2 hours of reaction, ion chromatography detects Cl - The residual amount is 6.2g and the removal rate is 83.5%.

[0046] Add 10% H dropwise to the salt chamber 3 PO 4 The pH of the solution was adjusted to 1 and allowed to stand for 30 min. After replacing the HCl solution in the acid chamber with 300ml of deionized water, a second stage of electrodialysis was performed. The control voltage is 10V, and the maximum current density is 10mA / cm ...

Embodiment 2

[0050] The method is the same as in Example 1, except that different experimental conditions are selected for separation. The results are shown in Table 1-3.

[0051] Table 1 Cl-removal rate under different pretreatment and primary electrodialysis conditions

[0052]

[0053] Table 2 AMP yield under different deprotection, two-stage electrodialysis and salt-forming conditions

[0054]

[0055] Note: *N AMP : Multiple of AMP moles

[0056] Table 3 Product purity and separation total yield obtained under different concentration, decolorization, crystallization and drying conditions

[0057]

[0058]

Embodiment 3

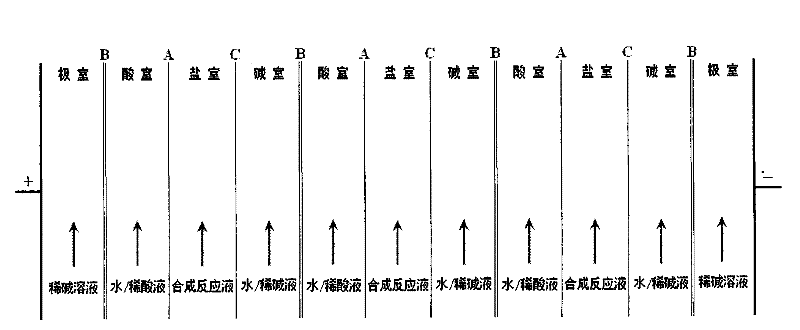

[0060] The same as the method of Example 1, the difference is that the electrodialyzer is assembled between a pair of electrodes with three groups of attached figure 1 Repeat unit membrane groups shown, forming multiple compartments, as attached figure 2 As shown, the compartment combination is anode chamber / acid chamber / salt chamber / alkali chamber / acid chamber / salt chamber / alkali chamber / acid chamber / salt chamber / alkali chamber / cathode chamber. The salt chamber was all poured into the reaction solution (5,6-O-isopropyl-AMP: 25.2g; Cl - : 47.5g; PO 4 3- : 20.6g) a total of 590ml. The primary electrodialysis control voltage is 18V, and the maximum current density is 30mA / cm 2 , reaction 1.5h, Cl - The residual amount is 3.1 g, and the removal rate is 93.4%. The condition of the second-stage electrodialysis is consistent with that of the first-stage electrodialysis. After 2 hours of reaction, the content of AMP in the acid chamber solution is 24.7 g, and the yield is 98%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com